A process and device for deep recovery and treatment of synthetic leather wastewater

A technology for recycling and processing synthetic leather, which is applied in the field of advanced recycling and treatment of synthetic leather wastewater and equipment, which can solve the problems of long residence time, large investment in equipment, and only consideration of recycling, etc., to reduce residence time, reduce separation equipment, and reduce decomposition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

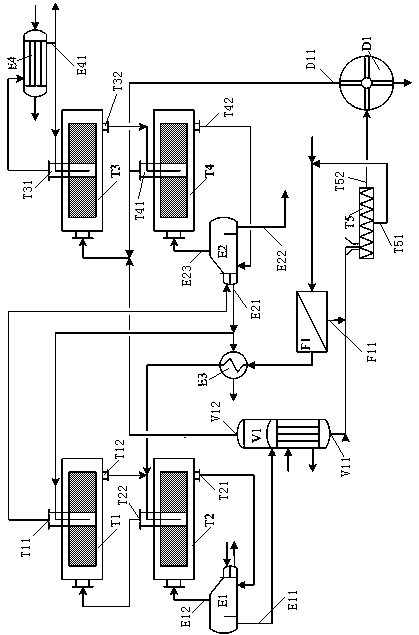

[0022] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

[0023] refer to figure 1

[0024] A synthetic leather wastewater advanced recovery treatment process, including a deep recovery treatment device composed of a DMF refining rectification system, a DMF dehydration rectification system, an evaporation system, a filtration system, a pressing system and a drying system, the steps are as follows:

[0025] 1) The DMF wastewater produced by synthetic leather is filtered through the filter system F1 to exchange heat with the steam condensate heated by the second reboiler E2 installed in the DMF refining and rectifying system (T3 and T4). DMF wastewater After preheating, it is transported into the DMF dehydration and rectification system (T1 and T2) in liquid form;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com