Heating system for natatorium

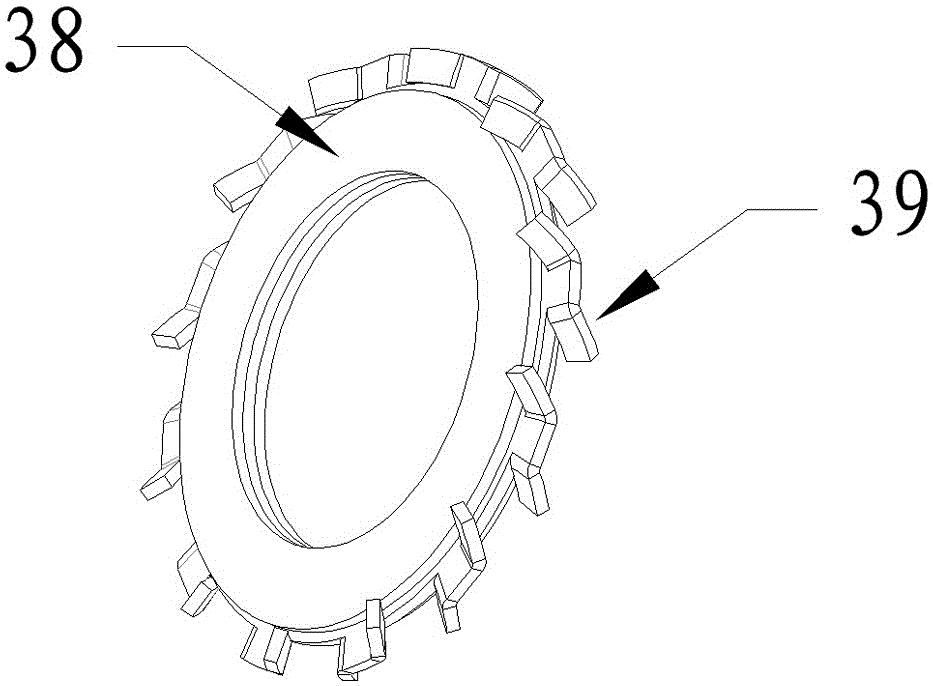

A technology for heating systems and swimming pools, which is applied in the field of heating systems for swimming pools, can solve problems such as difficulty in disassembly, achieve the effects of improving disassembly and assembly technology, facilitating repeated and quick assembly and disassembly, and enhancing axial elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

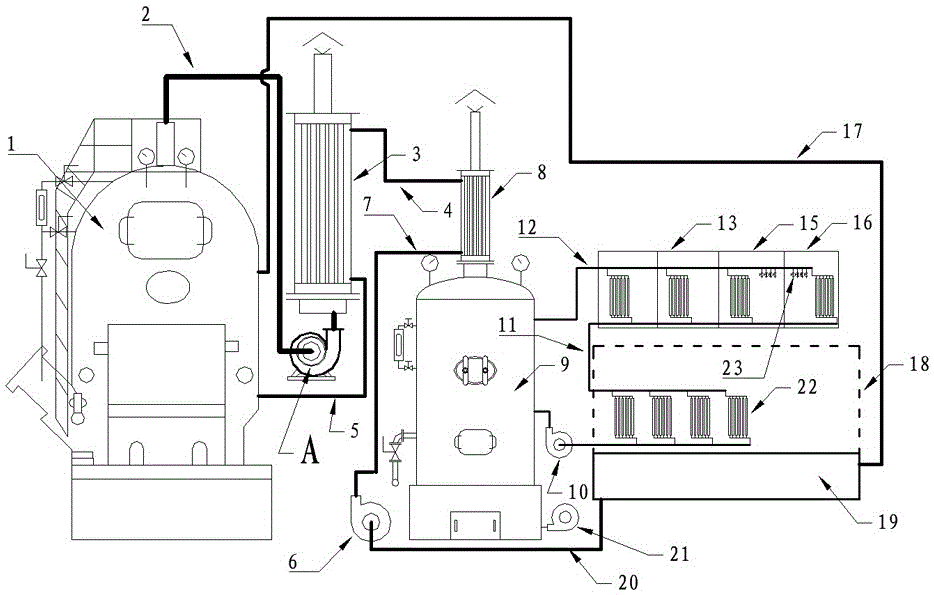

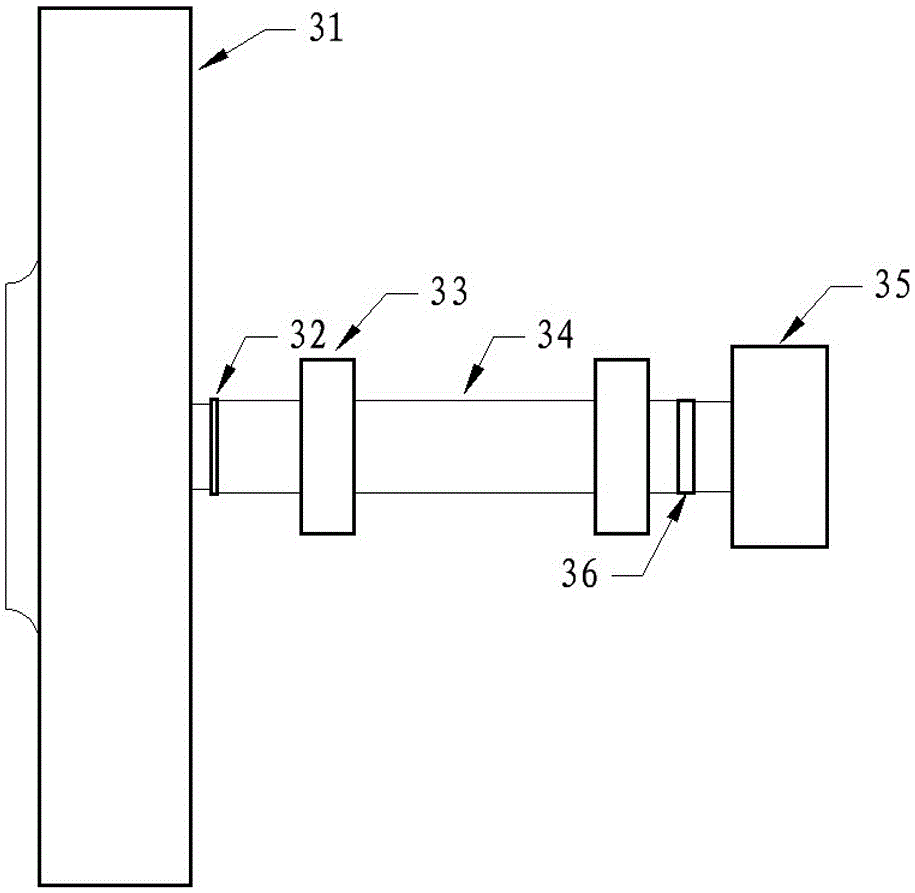

[0025] Now in conjunction with accompanying drawing, the present invention is described in further detail.

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 The heating system of the swimming pool shown in the figure includes a grate biomass boiler 1 and a fixed bed biomass boiler 9. The tail gas pipe 2 of the grate biomass boiler 1 is connected to the tube heat exchanger through the induced draft fan A and then 3 is emptied by the chimney. The tail gas pipe of the bed biomass boiler 9 is connected to the tube heat exchanger 8 and then emptied by the chimney; the hot water outlet pipe 17 of the grate biomass boiler is connected to the swimming pool 19, and the outlet pipe 20 of the swimming pool is connected and fixed successively through the pool water circulation pump 6 The tube heat exchanger of the bed biomass boiler and the grate biomass boiler is connected to the grate biomass boiler inlet pipe 5; the fixed bed biomass boiler 9 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com