Natural ester transformer oil and preparation method thereof

A technology of transformer oil and natural ester, applied in the field of transformer oil, can solve the problems of easy precipitation, short shelf life, poor stability of transformer oil, etc., and achieve the effect of slow increase of acid value, reduction of sludge amount, and good oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

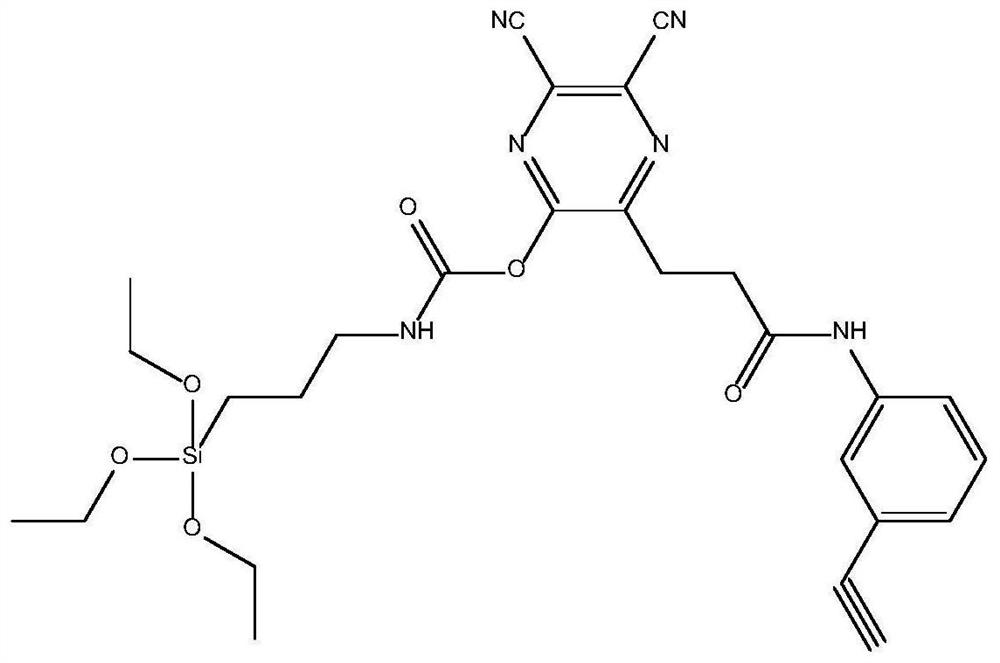

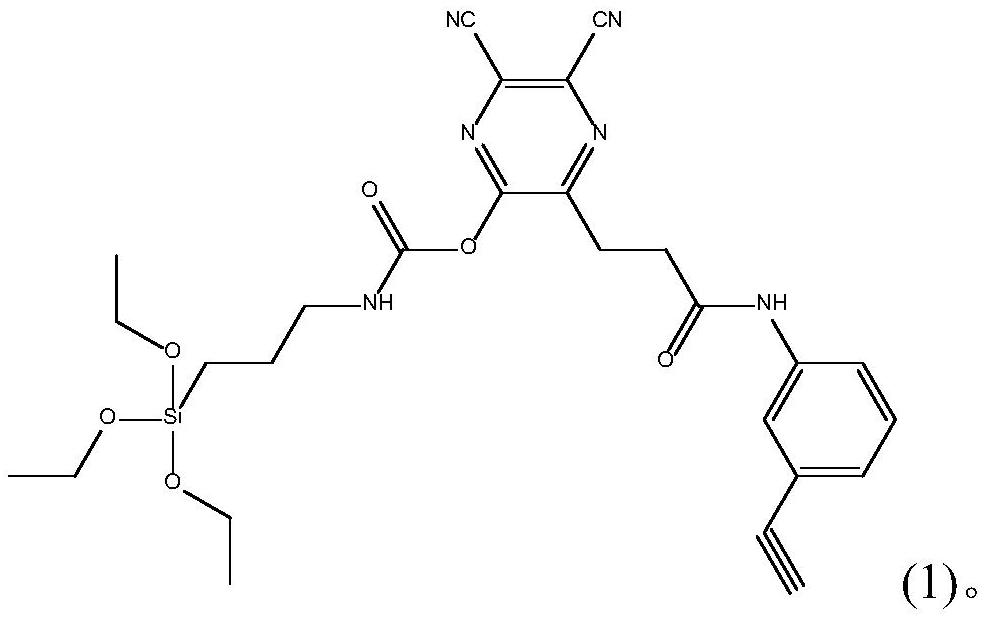

Image

Examples

Embodiment 1

[0081] This example provides a natural ester base oil derived from soybean oil:

[0082] -Alkali refining: soybean oil is heated to 40°C, stirred at 30r / min, and 40°C lye is added to the vegetable oil raw material by spraying method. The lye is 0.1% sodium hydroxide solution, and the amount added is 15% of the weight of soybean oil. , then stirred at 90r / min for 30min, then stirred at 30r / min for 25min, raised the temperature to 54°C at 3°C / min, stood still for 12h, took the upper layer of oil and washed it with soft water, and added soft water at 97°C in a uniform spraying method, and added The amount of water is 10% of the oil amount, and the time for adding water is 20 minutes;

[0083] -Decolorization: heat the oil after alkali refining to 100°C, add 5% of oil weight activated carbon and 2.5% activated clay to decolorize for 24 hours under stirring at 60r / min, filter impurities and sediment after decolorization is completed;

[0084] -Deacidification: under vacuum, the de...

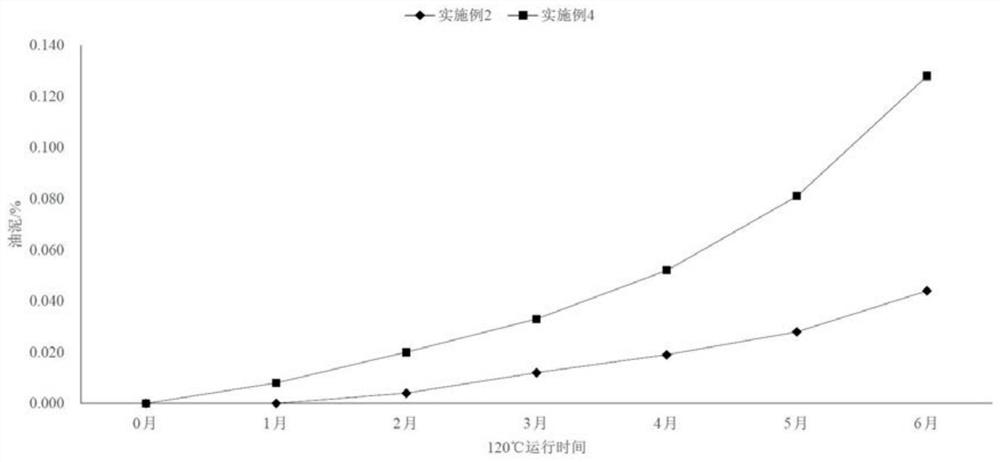

Embodiment 2

[0088] The present embodiment provides a kind of natural ester transformer oil, and its formula is as follows:

[0089] The natural ester base oil described in embodiment 1, 97.00%;

[0090] Modified aluminum nitride nanoparticles, 0.50%;

[0091] Modified silicon nitride nanoparticles, 1.25%;

[0092] Metal deactivator benzotriazole (BTA), 0.10%;

[0093] Pour point depressant T602HB, 1.0%;

[0094] Anti-photosensitizer HE1127 light stabilizer, 0.15%.

[0095] According to the formula quantity, add modified aluminum nitride nanoparticles and modified silicon nitride nanoparticles to the natural ester base oil described in Example 1, add metal passivation agent, pour point depressant and anti-light sensitivity agent after mixing, Add molecular sieves and absorb at 135°C for 4 hours to obtain natural ester transformer oil.

[0096] The preparation method of modified aluminum nitride nanoparticles is: get 10g nano aluminum nitride (particle diameter 30nm, density 2.72g / cm ...

Embodiment 3

[0100] This example provides another natural ester transformer oil, its formula and preparation method are basically the same as Example 1, the difference is that no modified aluminum nitride nanoparticles and modified aluminum nitride nanoparticles are added to the natural ester transformer oil in this example. Silicon nitride nanoparticles, the deficiency of which is made up with natural ester base oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com