Production method of vinyl acetate

A vinyl acetate and vinyl acetate technology, applied in the field of vinyl acetate production, can solve the problems of high energy consumption and low product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

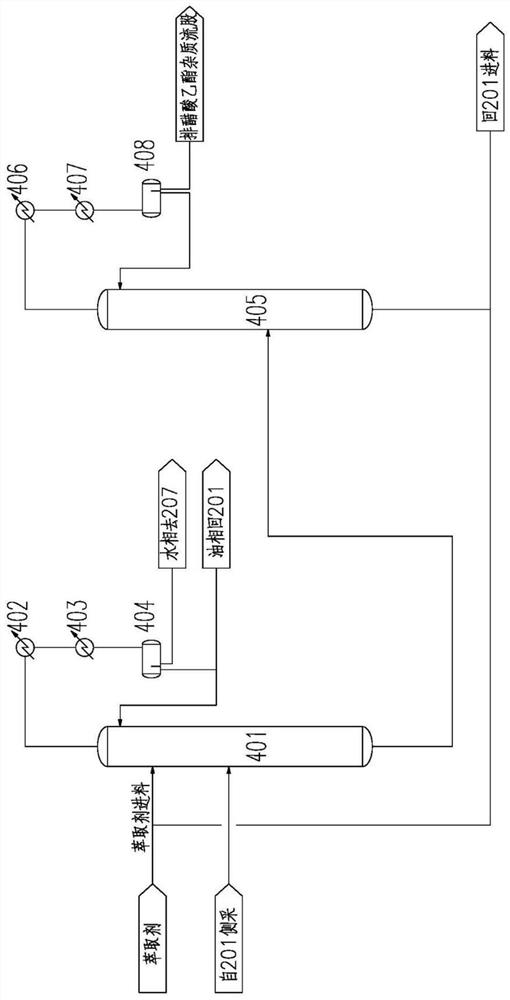

[0050] The method and device for removing ethyl acetate in the vinyl acetate production process proposed by the present invention mainly include an extractive distillation tower system and an ethyl acetate tower (405) system. The following is a description of the method and device of the present invention in conjunction with the accompanying drawings.

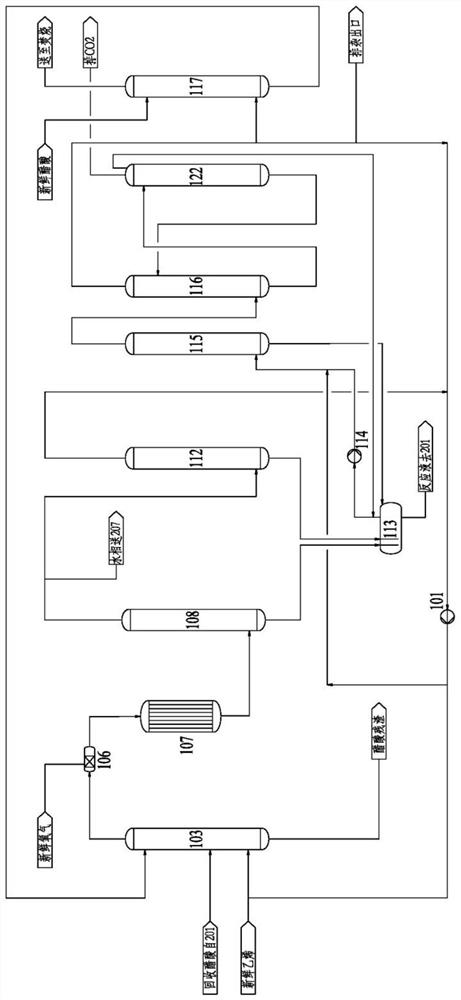

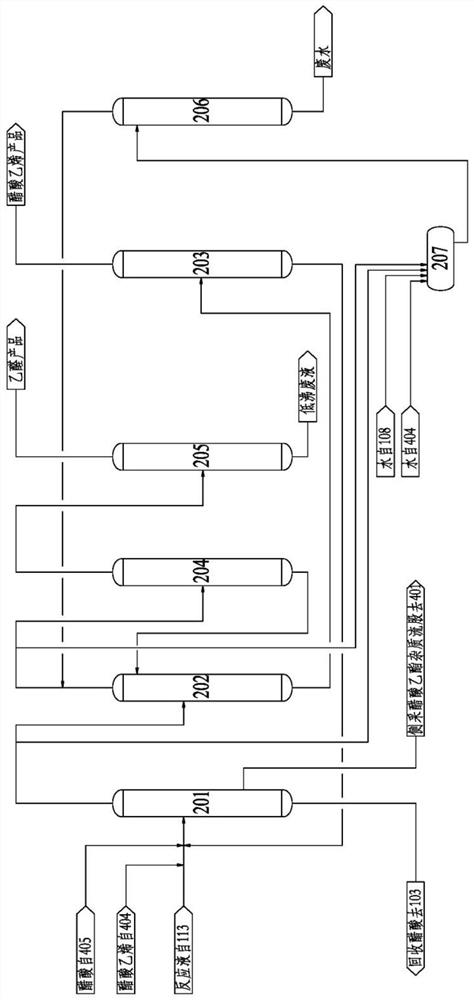

[0051] The present invention passes figure 1 , figure 2 , image 3 The method shown implements:

[0052] Specifically, fresh ethylene enters the lower part of the acetic acid evaporator (103) after being mixed with the circulating gas from the circulating gas compressor (101), and is mixed with the fresh acetic acid from the acetic acid tower (201) in the rectification section and the fresh acetic acid from the ethylene recovery tower (117). countercurrent contact. The mixed gas of ethylene and acetic acid obtained at the top of the acetic acid evaporator (103) is further mixed with fresh oxygen in the oxygen mixer (106) an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com