Unreinforced precast concrete thin-wall pile and manufacturing method and application thereof

A prefabricated concrete and thin-walled pile technology, applied in the field of prefabricated pile manufacturing, can solve the problems of poor economy, large amount of steel and high cost of foundation reinforcement scheme, and achieve high cost performance and practicability, improved bearing capacity, and large expansion area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

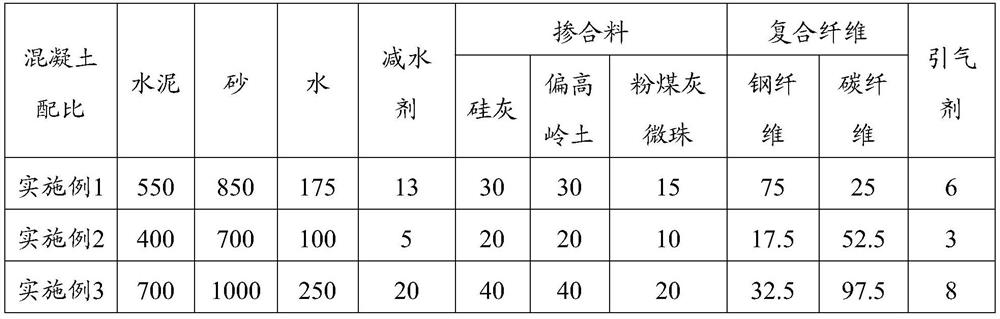

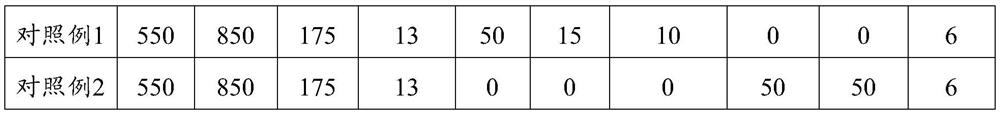

[0036] Step 1, preparation of ultra-high performance concrete:

[0037] Put sand, cement, and admixtures into a forced mixer and stir evenly. After adding about 30% of water while stirring, continue to add water reducing agent, air-entraining agent, composite fiber and the remaining water and continue stirring until the fluidity meets the requirements. According to the technical requirements, fresh concrete with a slump of 70-120mm is made.

[0038] Step 2. Make thin-walled piles:

[0039]The freshly mixed concrete after stirring is distributed, molded, and centrifugally formed to make pipe piles with a wall thickness of 30-50mm; After the concrete strength reaches the demoulding standard, remove the formwork and let it stand for a period of time, and then put it in an autoclave to continue the secondary curing, so that the concrete of the pile body can reach the strength standard of C80 and above when it leaves the factory.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com