Rapid heating electronic cigarette heating tube with carbon nanofiber membrane

A nano-carbon fiber, electronic cigarette technology, applied in tobacco and other directions, can solve the problems of poor thermal shock resistance, short service life, burnout, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

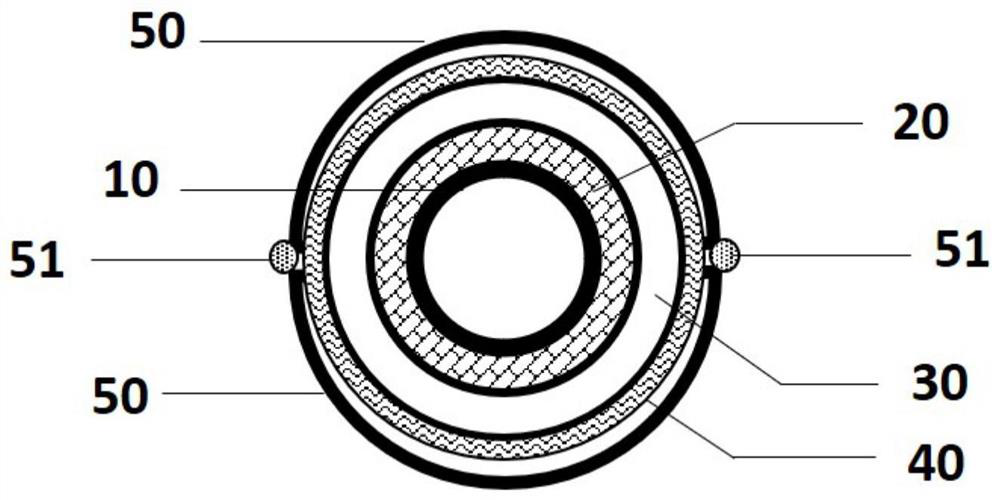

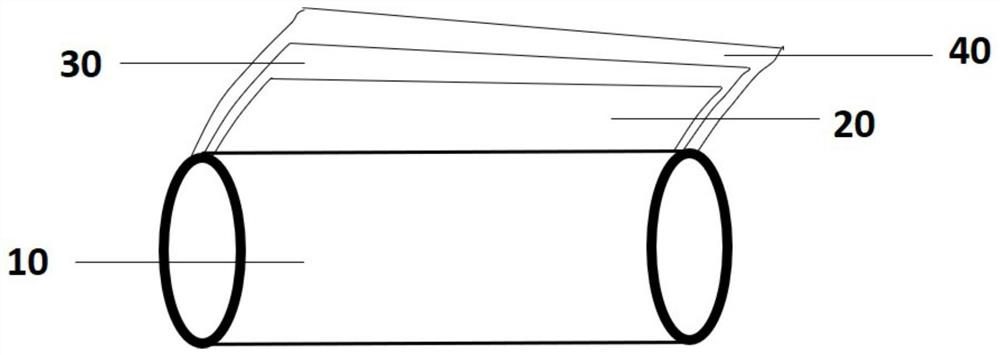

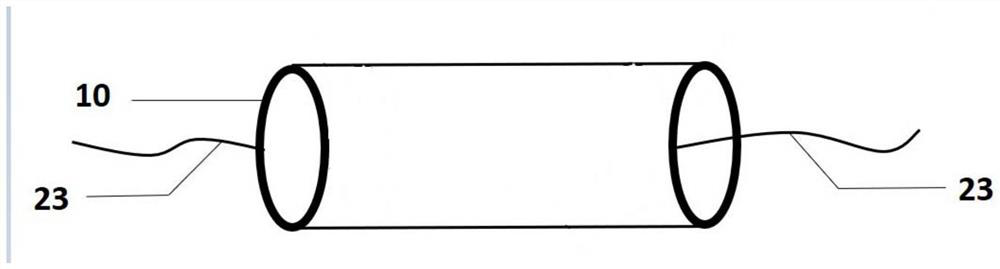

[0025] This embodiment relates to a nano-carbon fiber membrane rapid heating electronic cigarette heating tube, such as Figure 1-3 As shown, it includes: a hollow tube 10 , an electric heating layer 20 , an insulating and heat insulating layer 30 , an infrared reflection layer and a fixing layer 50 .

[0026] Specifically, the hollow tube 10 is used to accommodate tobacco leaves or cartridges. The electric heating layer 20 is coated on the outer wall of the hollow tube 10 and is electrically connected to the external circuit board for heating the tobacco leaves or cartridges placed in the hollow tube 10 . The insulation and heat insulation layer 30 covers the outer sidewall of the electric heating layer 20 . The insulating and heat insulating layer 30 is coated on the surface of the electric heating layer 20 to reduce the heat diffusion loss, enhance the heating effect of the hollow heating chamber, and reduce the temperature of the outer packaging to prevent hot hands. The...

Embodiment 2

[0032] Implementation example 2: the main difference between this embodiment and embodiment 1 is:

[0033] The graphitization treatment temperature of the carbon nanofiber film in the present invention is 2000° C., and the time is 2 hours, and the remaining conditions are the same as those in Example 1.

[0034]The nano-carbon fiber film prepared in this implementation example rapidly heats up the electronic cigarette heating tube. Under the voltage of 5V, the current is 1.6A, the temperature rises to 360°C within 3 seconds and maintains stable heat generation. After 4 hours of continuous power-on work, its resistance gradually increases to 5Ω. , the working temperature is gradually reduced to 290-310°C.

Embodiment 3

[0035] Implementation example 3: the main difference between this embodiment and embodiment 1 is:

[0036] The graphitization treatment temperature of the carbon nanofiber film in the present invention is 2800° C., and the time is 2 hours, and other conditions are the same as those in Example 1.

[0037] The nano-carbon fiber film prepared in this implementation example rapidly heats up the electronic cigarette heating tube. Under the voltage of 5V, the current is 2.1A, and the temperature rises to 400°C within 3 seconds and maintains stable heat. It works continuously for 1000h, and its resistance is 2.4Ω. Obviously, the working temperature is stable at 395-400°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com