Nickel phosphide/carbon/nickel phosphide composite material as well as preparation method and application thereof

A composite material, nickel phosphide technology, applied in the field of materials, can solve problems such as performance to be improved, and achieve the effects of improving reversible lithium intercalation capacity, improving rate performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

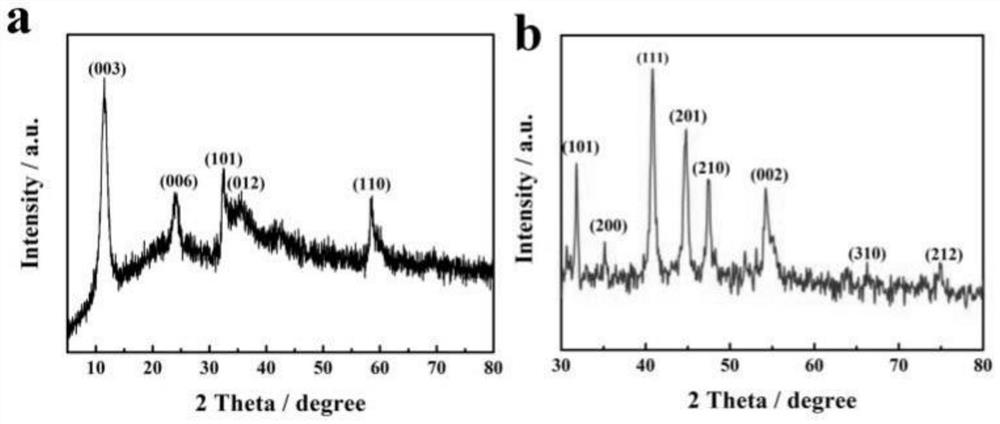

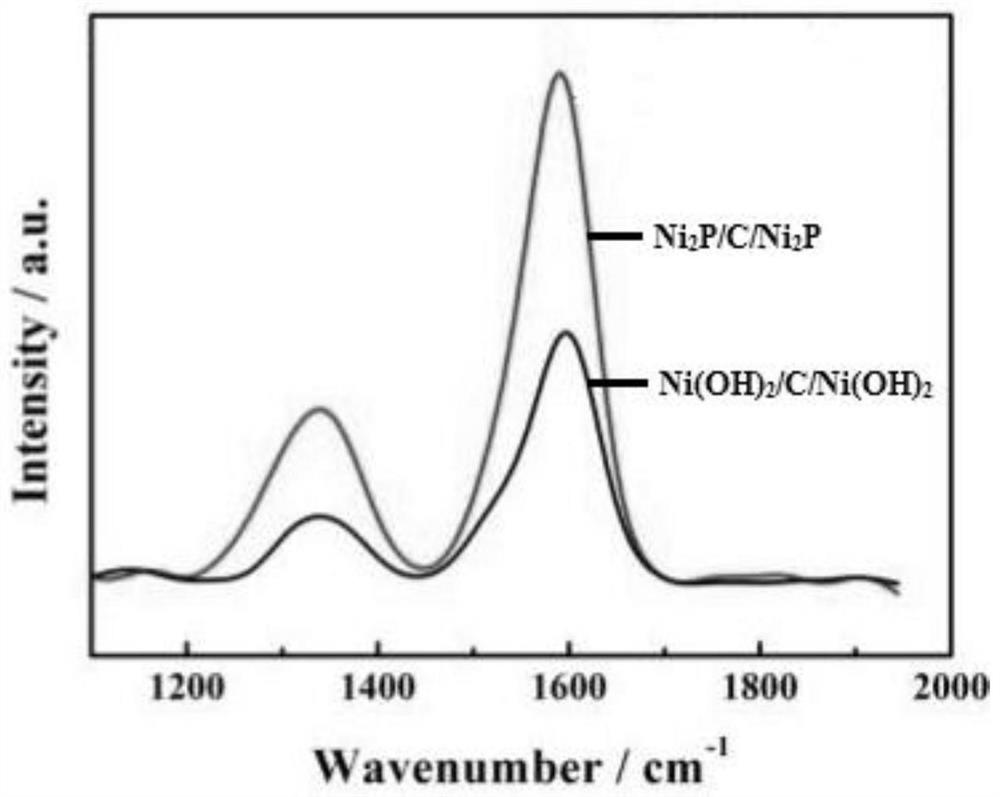

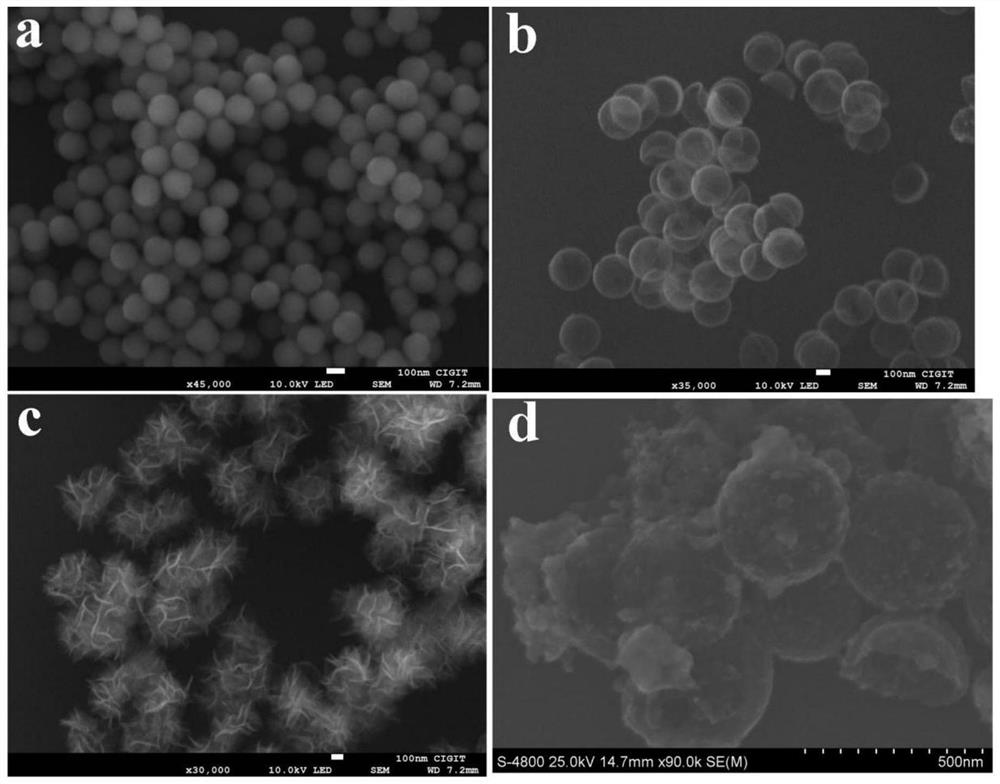

[0039] Preparation of Nickel Phosphide / Carbon / Nickel Phosphide Composite Materials

[0040] (1) SiO 2 The microspheres were dispersed in water, then formaldehyde and resorcinol were added, and the reaction was stirred for 24 hours to obtain SiO with a core-shell structure. 2 / resorcinol-formaldehyde oligomer complex, where SiO 2 The mass molar ratio of microspheres, formaldehyde and resorcinol is 300:0.0036:0.007, mg:mol:mol, SiO 2 / The resorcinol-formaldehyde oligomer complex was alternately washed with distilled water and absolute ethanol for 4 times, dried at 70°C to constant weight, and then placed in a tube furnace at 700°C for 5 hours under an argon atmosphere. Prepared SiO with core-shell structure 2 / C complex, and finally the SiO 2 / C complex was soaked in 2mol / L sodium hydroxide solution for 5h to remove SiO 2 SiO in / C composite 2 , to prepare hollow mesoporous carbon spheres;

[0041] (2) Dissolve urea, nickel nitrate and polyvinylpyrrolidone in ethanol solu...

Embodiment 2

[0054] Preparation of Nickel Phosphide / Carbon / Nickel Phosphide Composite Materials

[0055] (1) SiO 2 The microspheres were dispersed in water, then formaldehyde and resorcinol were added, and the reaction was stirred for 20 hours to obtain SiO with a core-shell structure. 2 / resorcinol-formaldehyde oligomer complex, where SiO 2 The mass molar ratio of microspheres, formaldehyde and resorcinol is 350:0.0038:0.008, mg:mol:mol, SiO 2 / The resorcinol-formaldehyde oligomer complex was alternately washed with distilled water and absolute ethanol for 3 times, dried at 85°C to constant weight, and then placed in a tube furnace at 800°C for 3 hours under a helium atmosphere. Prepared SiO with core-shell structure 2 / C complex, and finally the SiO 2 / C complex was soaked in 3mol / L sodium hydroxide solution for 4h to remove SiO 2 SiO in / C composite 2 , to prepare hollow mesoporous carbon spheres;

[0056] (2) urea, nickel nitrate and polyvinylpyrrolidone are dissolved in ethanol...

Embodiment 3

[0059] Preparation of Nickel Phosphide / Carbon / Nickel Phosphide Composite Materials

[0060] (1) SiO 2 The microspheres were dispersed in water, then formaldehyde and resorcinol were added, and the reaction was stirred for 22 hours to obtain SiO with a core-shell structure. 2 / resorcinol-formaldehyde oligomer complex, where SiO 2 The mass molar ratio of microspheres, formaldehyde and resorcinol is 320:0.004:0.007, mg:mol:mol, SiO 2 / The resorcinol-formaldehyde oligomer complex was alternately washed twice with distilled water and absolute ethanol, dried at 100°C to constant weight, and then placed in a tube furnace at 750°C for 4 hours under an argon atmosphere. Prepared SiO with core-shell structure 2 / C complex, and finally the SiO 2 / C complex was soaked in 5mol / L sodium hydroxide solution for 3h to remove SiO 2 SiO in / C composite 2 , to prepare hollow mesoporous carbon spheres;

[0061] (2) urea, nickel nitrate and polyvinylpyrrolidone are dissolved in ethanol solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com