Mini LED device packaging method and Mini LED device packaging structure

A device packaging and substrate technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of large size, poor heat dissipation of the LED device base, and inability to flexibly control the light-emitting angle, so as to improve the service life and prevent damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

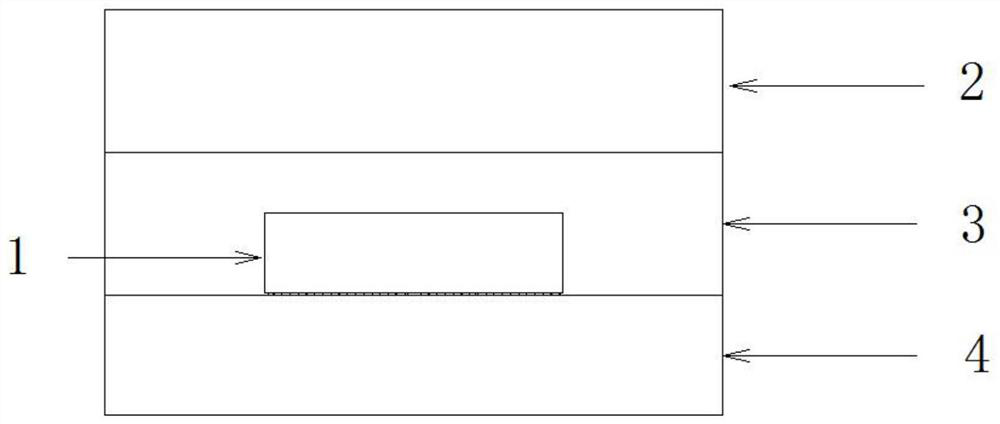

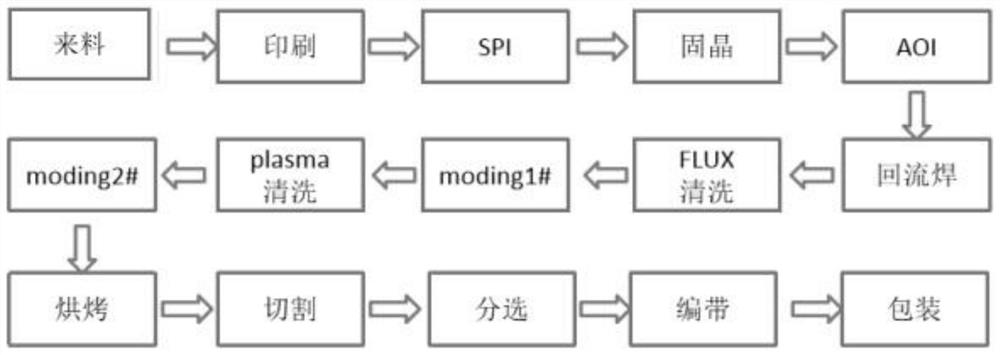

[0062] Embodiment one, such as Figure 1-2 shown;

[0063] Step 1: Preparation and inspection of incoming materials;

[0064] Step 2: printing solder on the substrate 4;

[0065] Step 3: After the printed solder substrate 4 is tested by SPI, the Mini LED chip 1 is solidified on the substrate 4;

[0066] Step 4: After the substrate 4 with the crystal bonding completed is tested by AOI, reflow soldering is performed, and the Mini LED chip 1 is soldered to the front side of the substrate 4;

[0067] Step 5: Clean the residues and impurities on Mini LED chip 1 and the side of Mini LED chip 1;

[0068] Step 6: Molding with transparent glue material to complete the first glue layer 3;

[0069] Step 7: Bake to cure the first adhesive layer 3;

[0070] Step 8: Perform PLASMA cleaning;

[0071] Step 9: Molding with opaque white highly reflective glue material to complete the second glue layer 2;

[0072] Step 10: Bake again to fully cure the second adhesive layer 2;

[0073] St...

Embodiment 2

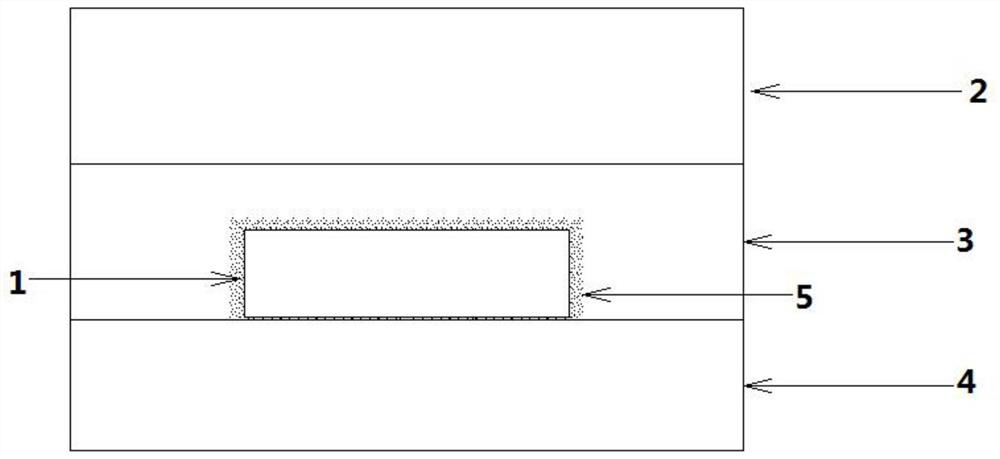

[0076] Embodiment two, such as Figure 3-4 shown;

[0077] Step 1: Preparation and inspection of incoming materials;

[0078] Step 2: printing solder on the substrate 4;

[0079] Step 3: After the printed solder substrate 4 is tested by SPI, the Mini LED chip 1 is solidified on the substrate 4;

[0080] Step 4: After the substrate 4 with the crystal bonding completed is tested by AOI, reflow soldering is performed, and the Mini LED chip 1 is soldered to the front side of the substrate 4;

[0081] Step 5: Clean the residues and impurities on the Mini LED chip 1 and the peripheral side of the Mini LED chip 1, and then use the powder spraying process to mix the glue of phosphor particles on the Mini LED chip 1 to obtain the powder spray glue layer 5;

[0082] Step 6: Molding with transparent glue material to complete the first glue layer 3;

[0083] Step 7: Bake to cure the first adhesive layer 3;

[0084] Step 8: Perform PLASMA cleaning;

[0085] Step 9: Molding with opaqu...

Embodiment 3

[0090] Embodiment three, such as Figure 5-6 shown;

[0091] Step 1: Preparation and inspection of incoming materials;

[0092] Step 2: printing solder on the substrate 4;

[0093] Step 3: After the printed solder substrate 4 is tested by SPI, the Mini LED chip 1 is solidified on the substrate 4;

[0094] Step 4: After the substrate 4 with the crystal bonding completed is tested by AOI, reflow soldering is performed, and the Mini LED chip 1 is soldered to the front side of the substrate 4;

[0095] Step 5: Clean the residues and impurities on Mini LED chip 1 and the side of Mini LED chip 1;

[0096] Step 6: Molding with the glue material mixed with phosphor particles to complete the phosphor glue layer 6;

[0097] Step 7: Bake to cure the first adhesive layer 3;

[0098] Step 8: Perform PLASMA cleaning;

[0099] Step 9: Molding with opaque white highly reflective glue material to complete the second glue layer 2;

[0100] Step 10: Bake again to fully cure the second adh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com