Environment-friendly paper waste incineration device with material turning function

A garbage incineration, environmental protection technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of lack of material turning function, poor incineration effect, affecting the user experience of the incineration device, etc., to achieve good incineration effect and structure Simple, enhance the effect of user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

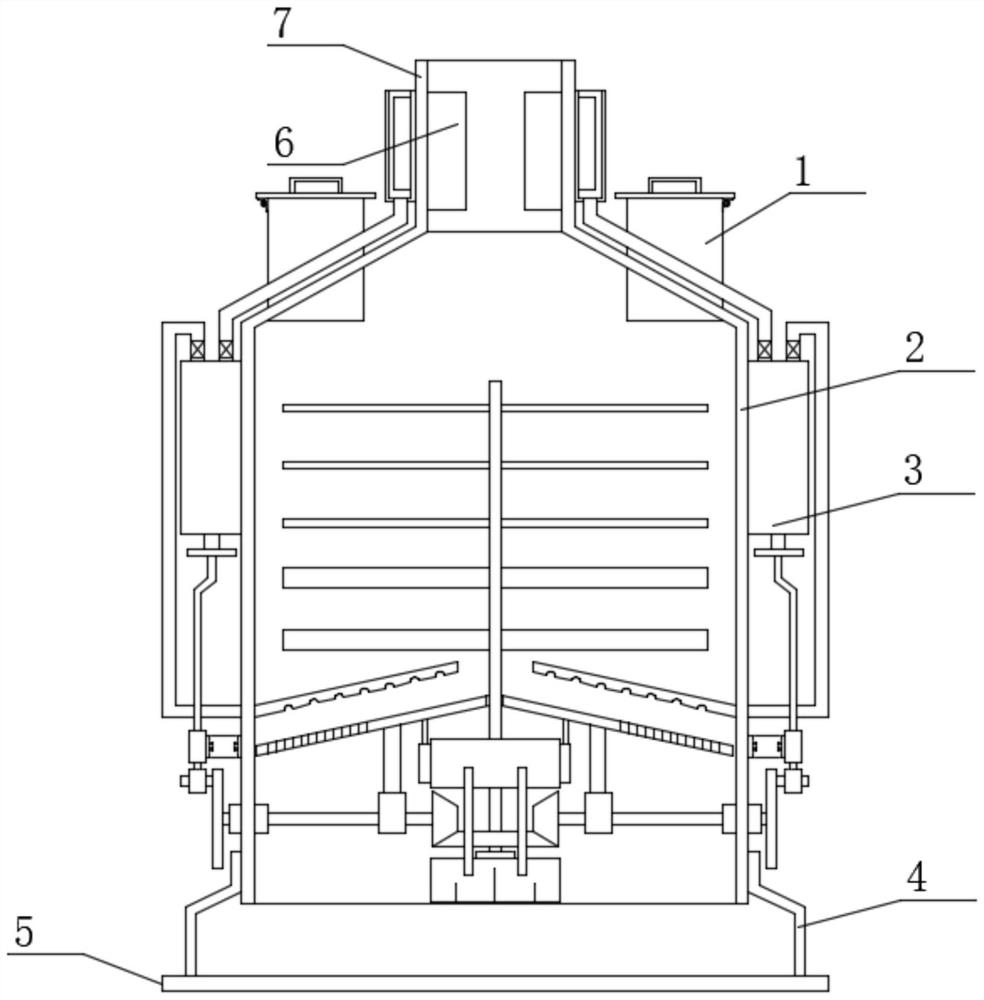

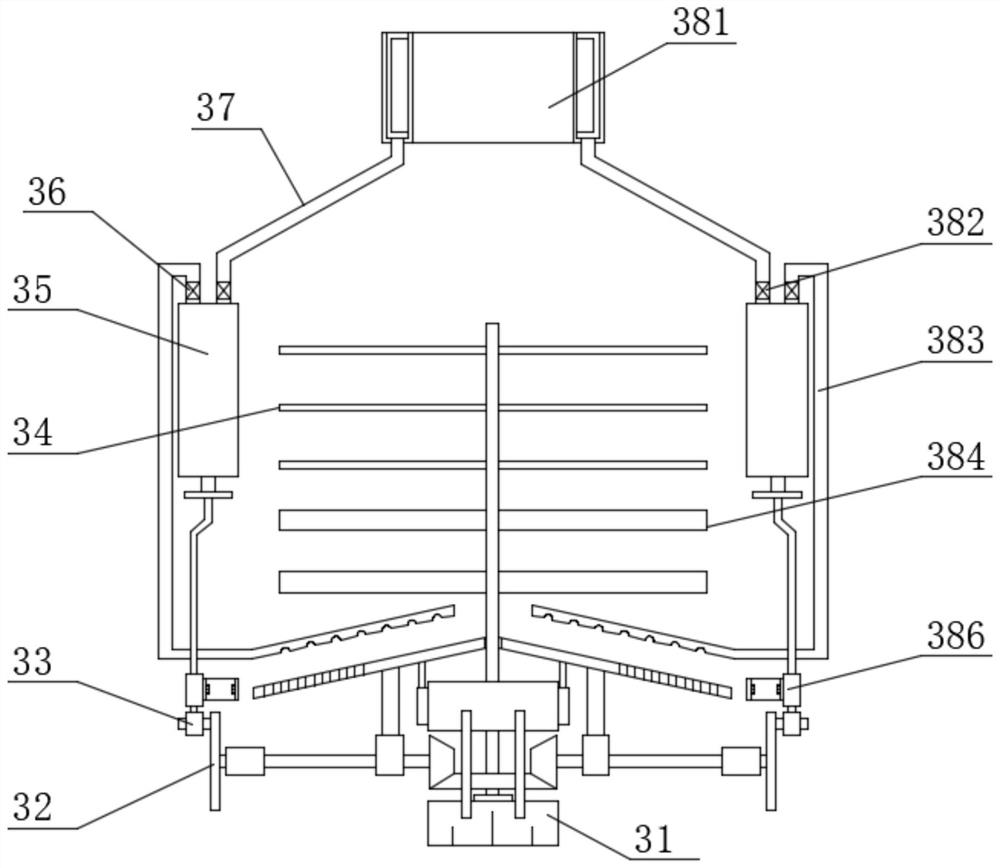

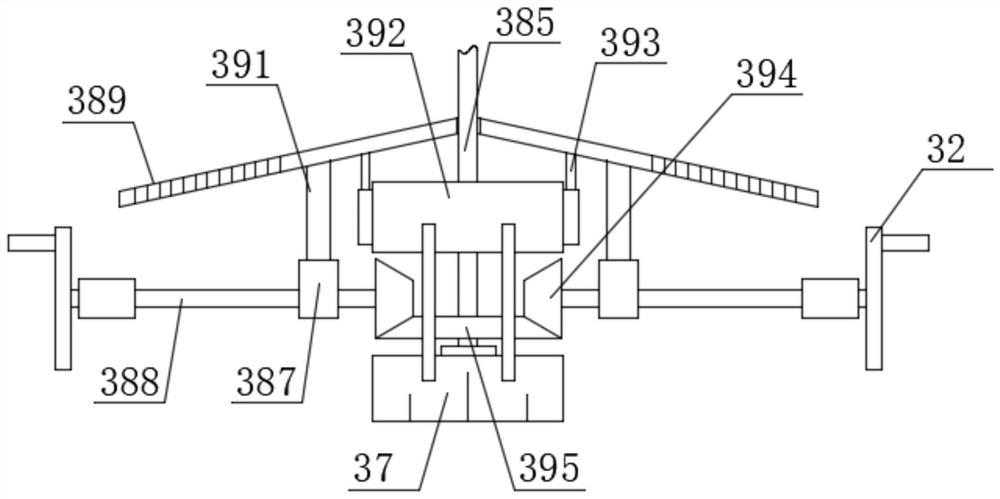

[0024] see Figure 1-Figure 4 , the present invention provides a technical solution: an environmentally friendly paper waste incineration device with material turning function, comprising a furnace body 2, the top of the furnace body 2 is welded with a feed pipe 1, and the middle part of the upper surface of the furnace body 2 is welded The exhaust pipe 7 is fixedly connected, the bottom of the furnace body 2 is provided with a support base plate 5, the two ends of the upper surface of the support base plate 5 are provided with support feet 4 corresponding to the furnace body 2, and the bottom end of the furnace body 2 is provided with a flip The material mechanism 3, the material turning mechanism 3 comprises a drive motor 31, a gearbox 392 is arranged above the drive motor 31, a drive shaft 385 is provided at the output end of the gearbox 392, and a crushing knife 34 is fixedly connected to the top of the drive shaft 385 by welding. , the bottom end of the drive shaft 385 is...

Embodiment 2

[0032] On the basis of Embodiment 1, in order to enrich the functions of the garbage incinerator, in this embodiment, preferably, a heater 381 corresponding to the intake pipe 37 is arranged above the piston cylinder 35, and the two ends of the heater 381 Screws are provided, and the heater 381 is fixed on the exhaust pipe 7 through the screws at both ends;

[0033]During use, the heater 381 is heated through the exhaust pipe 7, so that the gas blown into the furnace body 2 is heated through the heater 381, so as to prevent the incineration device from affecting the incineration effect of the garbage due to the low blowing temperature;

[0034] In order to make the heating effect of the heater 381 better, in this embodiment, preferably, the inside of the heater 381 is provided with a second heating fin 396, the second heating fin 396 is a rectangular parallelepiped structure, and the second heating fin 396 is made of copper, and the second heating fin 396 is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com