Air bag type pipeline isolator

A balloon type, isolator technology, applied in the direction of pipe components, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problem that protective measures cannot provide effective protection, maintain durability and reliability, and improve personal safety. , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

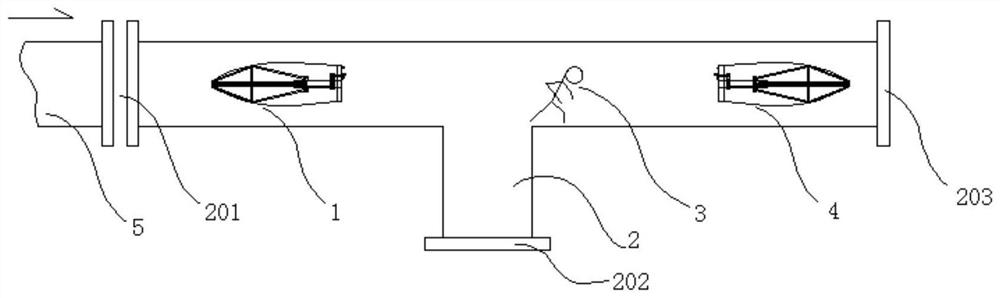

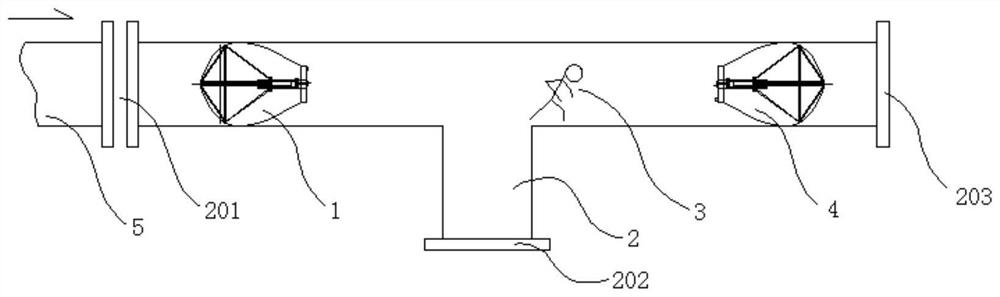

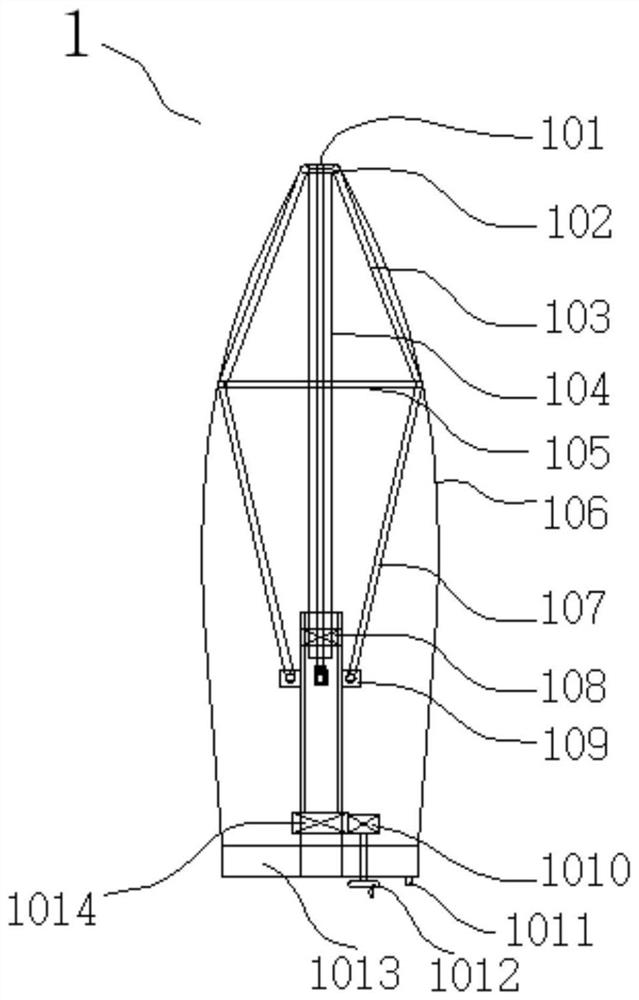

[0044] Such as Figure 1 to Figure 8 As shown, the airbag-type pipeline isolator of the present invention includes an airbag 106, a pressure gas source 2 that supplies air to the airbag 106 through a pipeline, a linear drive mechanism and a plurality of movable supports 1017 that are all located inside the airbag 106, and the airbag 106 is a rotating body, and its two ends are telescopic end and fixed end respectively, and the driving direction of described driving mechanism is parallel with the axis of air bag 106, and it is fixed on the fixed end, and its driving end is connected with telescopic end, and described movable bracket 1017 includes the detection end movable bracket 103 and the isolation section movable bracket 107 which are sequentially hinged, and the ends of the detection end movable bracket 103 and the isolation section movable bracket 107 which are far away from each other are respectively hinged to the telescopic end and the fixed end.

[0045] A plurality o...

Embodiment 2

[0051] This embodiment is to illustrate the implementation of the drive mechanism.

[0052] The driving mechanism can adopt pneumatic rod, hydraulic rod screw mechanism and the like. The present invention specifically adopts the screw mandrel structure that can be directly manually driven, and the specific implementation is as follows:

[0053] Such as image 3 , Figure 4 as well as Figure 7 As shown, in the present invention, the drive mechanism includes a positioning tube 104 connected in sequence, a transmission gear sleeve 1014, and a hand wheel 1012 that drives the transmission gear sleeve 1014 to rotate around its own axis through a gear drive assembly. One end of the positioning tube 104 It is connected with the telescopic end, and its other end is inserted into the transmission gear sleeve 1014 and screwed therewith. The transmission gear sleeve 1014 is rotatably mounted on the fixed end, and the hand wheel 1012 is located outside the airbag 106 .

[0054] Furthe...

Embodiment 3

[0059] This embodiment is based on the above embodiments to further illustrate the implementation of the present invention.

[0060] Such as image 3 , Figure 4 as well as Figure 7 As shown, in the present invention, a fixing ring 1011 is installed on the side of the fixing end away from the inner cavity of the airbag 106 .

[0061] Located at the fixed end of the airbag-type pipeline isolator 1, when the pipeline used is a pipeline with a large inclination angle and a vertical state, the fixing ring 1011 is easy to fall or cannot be fixedly installed when the airbag-type pipeline isolator 1 is installed and disassembled fixed safety device. Specifically, an iron chain or a rope is connected to the fixing ring 1011, thereby connecting the airbag-type pipeline isolator 1 to one end of the iron chain or rope, and the other end of the iron chain or rope is connected to a fixable structure outside the pipeline, and then Keep the effective work of the airbag type pipeline iso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com