Nonlinear automobile exhaust pipe with inner wall self-cleaning function

A kind of automobile exhaust, nonlinear technology, applied in the direction of exhaust device, internal combustion piston engine, muffler device, etc., can solve the problems of tailpipe blockage, difficult particle cleaning, affecting the normal exhaust of tailpipe, etc., to reduce friction The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

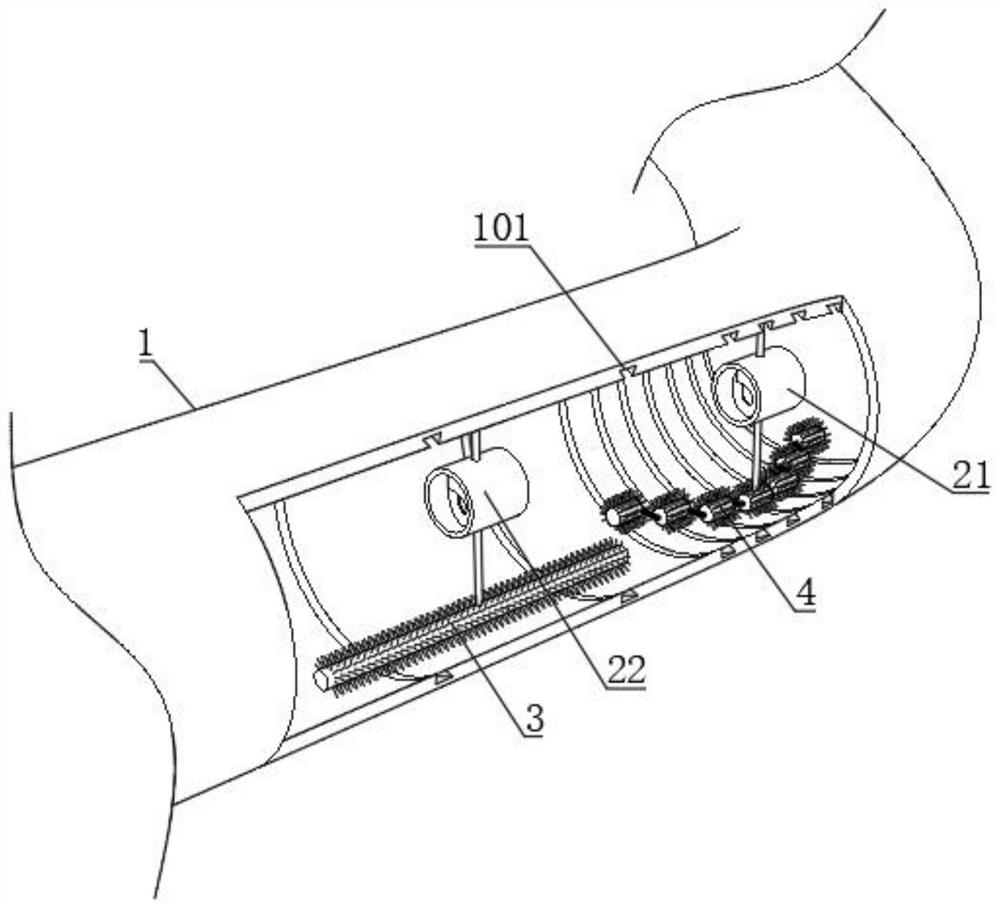

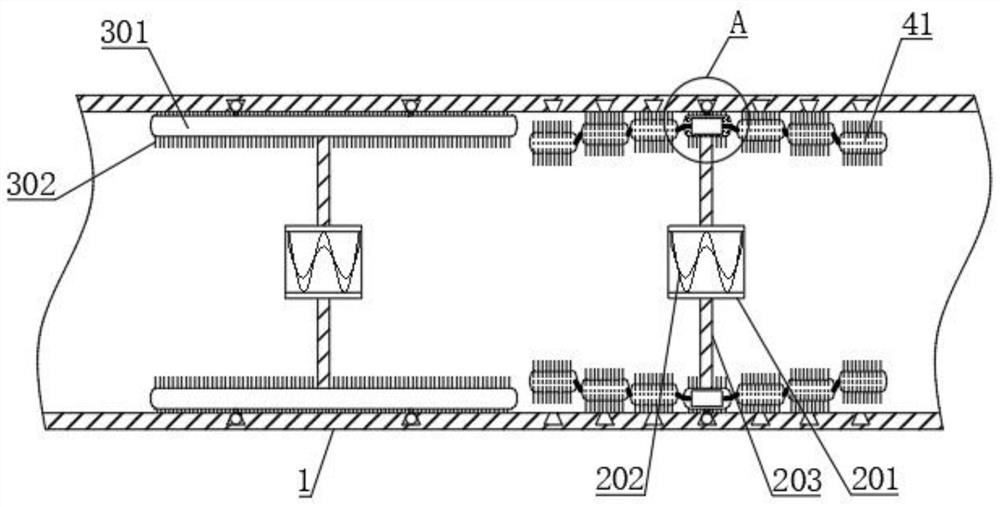

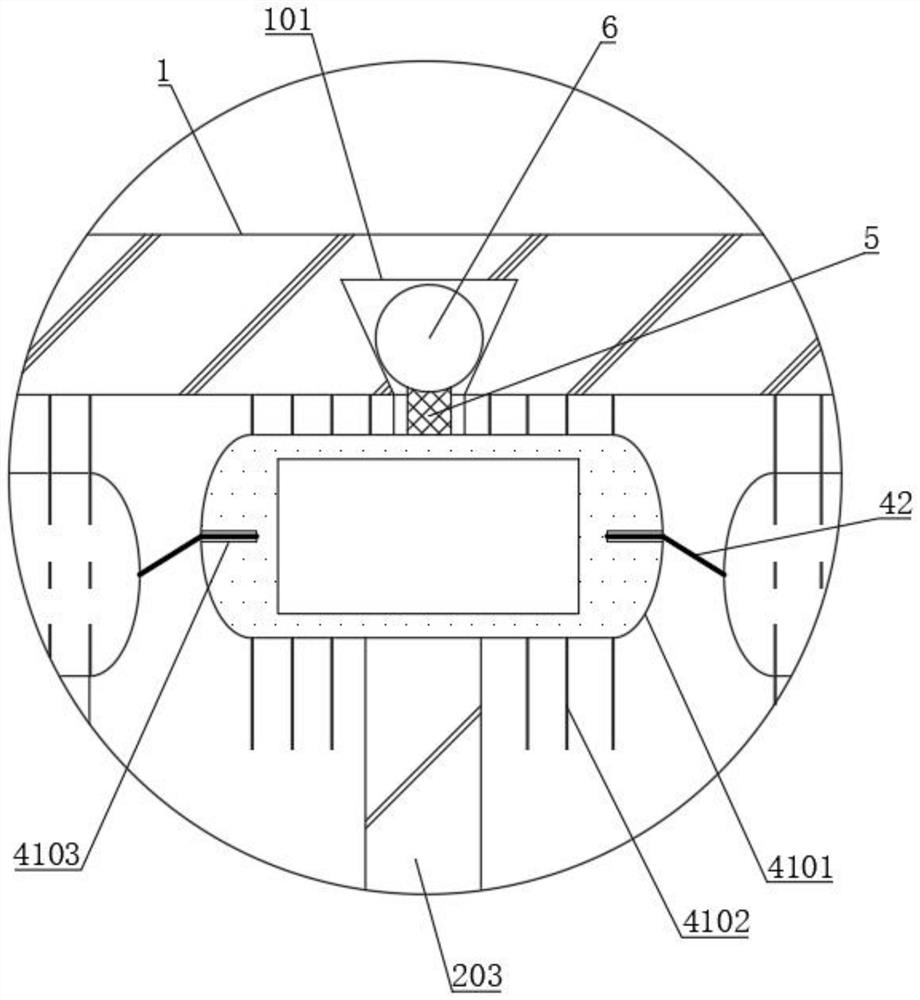

[0042] see figure 1 and figure 2 , a nonlinear automobile exhaust pipe with inner wall self-cleaning function, comprising a nonlinear exhaust pipe 1, a plurality of main in-situ rotating frames 21 and a plurality of secondary in-situ rotating frames are arranged inside the nonlinear exhaust pipe 1 22. Both the main in-situ rotating frame 21 and the auxiliary in-situ rotating frame 22 are located on the center line of the nonlinear exhaust pipe 1, the main in-situ rotating frame 21 is located in the linear area of the nonlinear exhaust pipe 1, and the auxiliary in-situ rotating frame The frame 22 is located in the bending area of the nonlinear exhaust pipe 1. A pair of bulk cleaners 4 are fixedly connected to the main in-situ rotating frame 21, and a pair of linear cleaners 3 are fixedly connected to the secondary in-situ rotating frame 22. Both the frame 21 and the auxiliary in-situ rotating frame 22 include a drum 201, a spiral plate 202 and a pair of struts 203, the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com