Manufacturing process of terrazzo-imitating porcelain plate and product obtained by applying process

A manufacturing process and terrazzo technology, applied in manufacturing tools, ceramic molding machines, ceramic molding workshops, etc., can solve the problem of inability to produce sharp-edged tablets, and achieve the effects of simple installation, strong product competitiveness, and low input cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

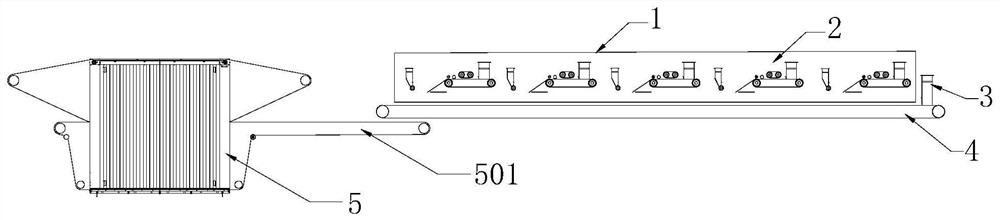

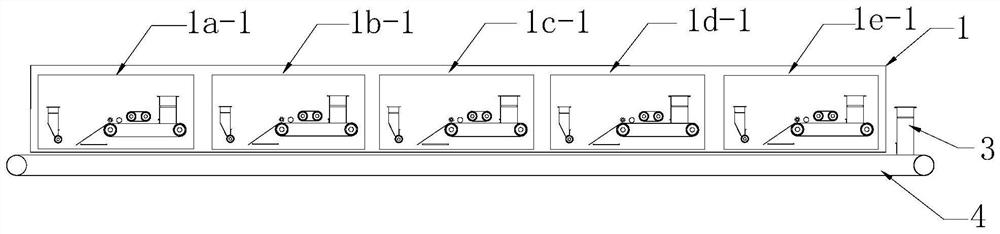

[0066]referenceFigure 1~4, This embodiment discloses a manufacturing process of imitation terrazzo porcelain plate, including the following process steps:

[0067]Step S1: Equipment installation

[0068]The manufacturing equipment used in this embodiment includes a ceramic powder compressed tablet module 1. The ceramic powder compressed tablet module 1 consists of 1 to 5 sets of ceramic powder compressed tablet particle modules 2. In this embodiment, 5 sets are provided Ceramic powder compressed tablet particle module 2, respectively 1a-1, 1b-1, 1c-1, 1d-1, 1e-1, ceramic powder compressed tablet module 1 and front lower hopper 3, receiving belt 4 Combined into an integrated cloth system, installed on a production line equipped with a ceramic press. The production line of the ceramic press includes a press 5 and a belt conveyor carrier 501. The press 5 is connected to the belt conveyor carrier 501. The belt conveyor carrier 501 Undertake the mixture conveyed by the belt 4 and convey it to ...

Embodiment 2

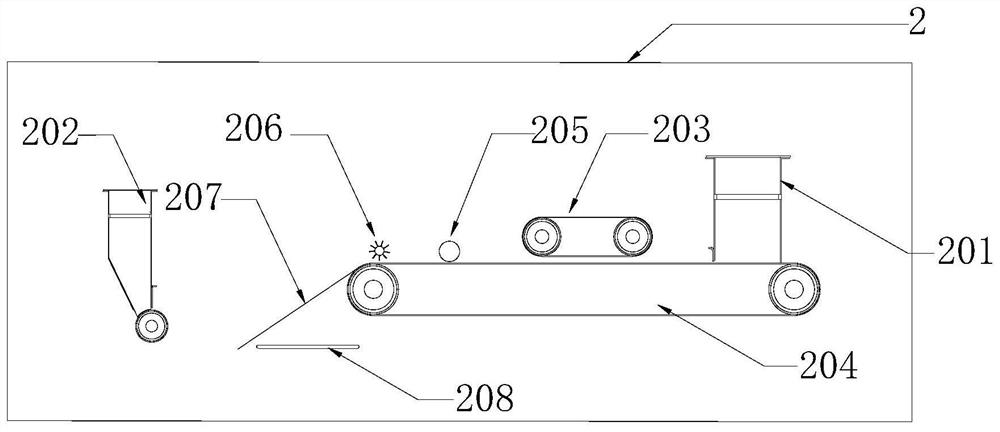

[0092]referenceFigure 5 This embodiment discloses another terrazzo-like porcelain plate manufacturing process, which is based on embodiment 1, and differs from embodiment 1 in:

[0093]In this embodiment, a cavity type stamping press is used, and the cavity type stamping press 5 includes a frame feeding grid 6 and a conveying belt connected to the press 5;

[0094]In step 5.1, the overall mixed raw material layout is formed with the rotation of the conveyor belt and is framed by the frame feeding grid 6 and carried to the mold cavity position of the punch press. The mold cavity is lowered and the raw materials in the frame feeding grid 6 fall into In the mold cavity, the frame feeding grid 6 immediately retreats to the conveyor belt for the second round of frame feeding. At the same time, the press 5 starts to press to make a blank. The frame feeding grid 6 frames the second round of mixed blank raw materials along with the front The placed powder pusher (not shown in the figure) moves fo...

Embodiment 3

[0097]referenceFigure 6 This embodiment discloses another terrazzo-like porcelain plate manufacturing process, which is based on the above embodiment and differs from the above embodiment in:

[0098]In this embodiment, a transition belt 7 is provided under the replenishing hopper 202 and the mesh-shaped flat slide 207. In step S4, the transition belt 7 first receives the flakes that are filtered and screened by the mesh-shaped flat slide 207, and then The replenishing hopper 202 drops the predetermined single-color powder or the predetermined 2-8 single-color powders uniformly or unevenly mixed on the pellets, and then spreads through the transition belt 7. 4 on.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com