Five-axis linkage gantry type numerical control cutting system for full-automatic tapping of end socket

A five-axis linkage and cutting system technology, which is applied in welding equipment, gas flame welding equipment, metal processing equipment, etc., can solve the problems of difficult processing, inaccurate head opening processing, etc., achieve smooth cutting surface and save correction time , Guarantee the effect of opening precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

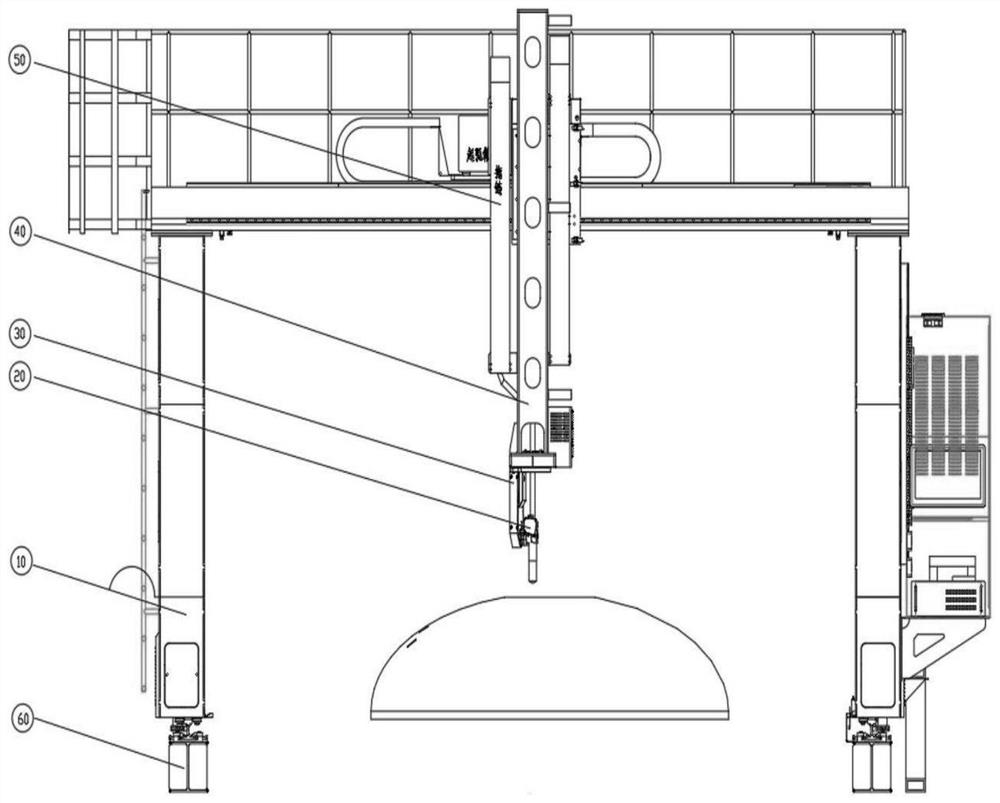

[0027] Attached below Figure 1-9 The specific implementation manner of the present invention will be described in further detail.

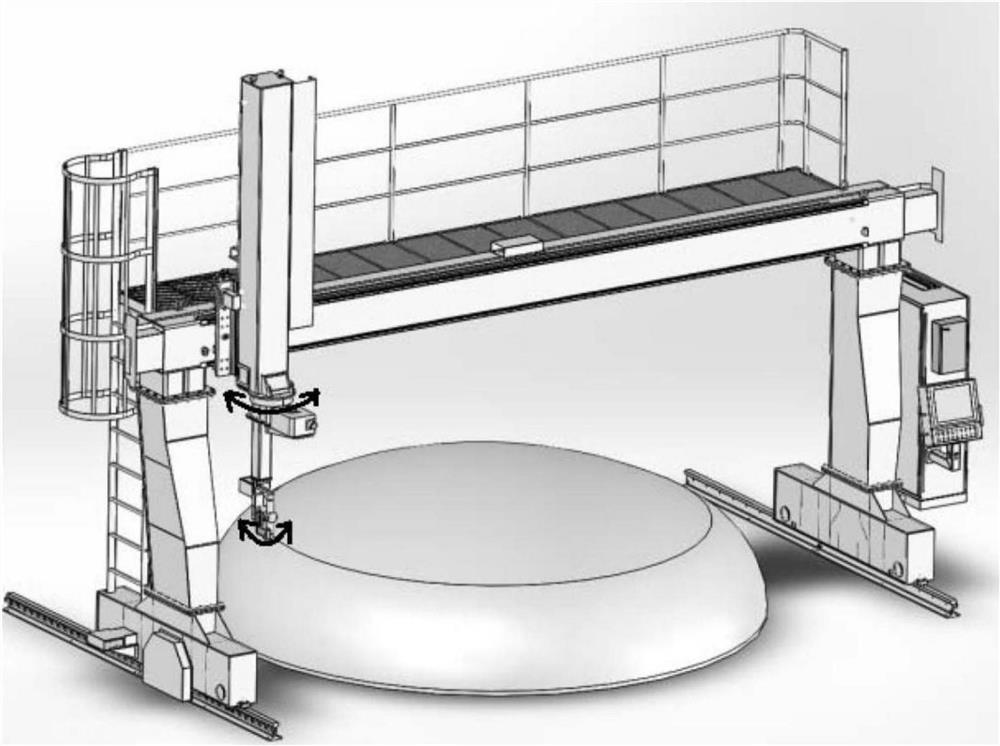

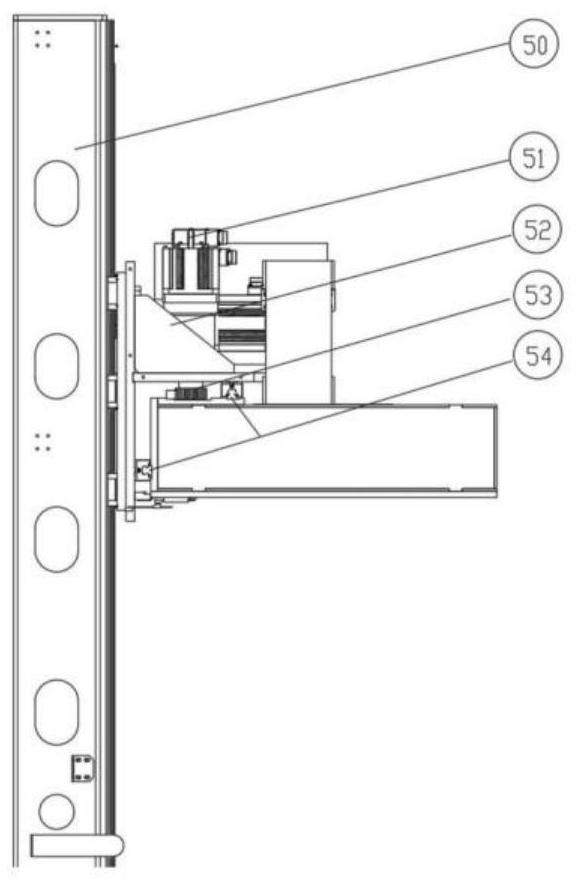

[0028] Such as Figure 1-9 As shown, the present invention includes a support frame 10 that slides in the front and rear directions. The upper end of the support frame 10 is provided with a horizontally moving trolley 50 that slides horizontally. The slewing support 30 that rotates in the horizontal plane, the right end of the slewing support 30 is rotatably connected with the torch deflection 20 structure.

[0029] The support frame 10 is a gantry-shaped structure;

[0030] It also includes a base platform 60 on which the support frame 10 is slidably placed.

[0031] The structure of the torch swing 20 includes a torch, the torch is rotatably connected to the slewing support 30 , and the upper end of the torch is fixedly connected to a wired laser vision sensor 24 .

[0032] A part of the head-type container is connected to the cylinder by w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com