Pop-top can pull ring forming equipment

A technology for forming equipment and cans, which is applied to metal processing equipment, feeding devices, positioning devices, etc., to achieve the effect of rapid stamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

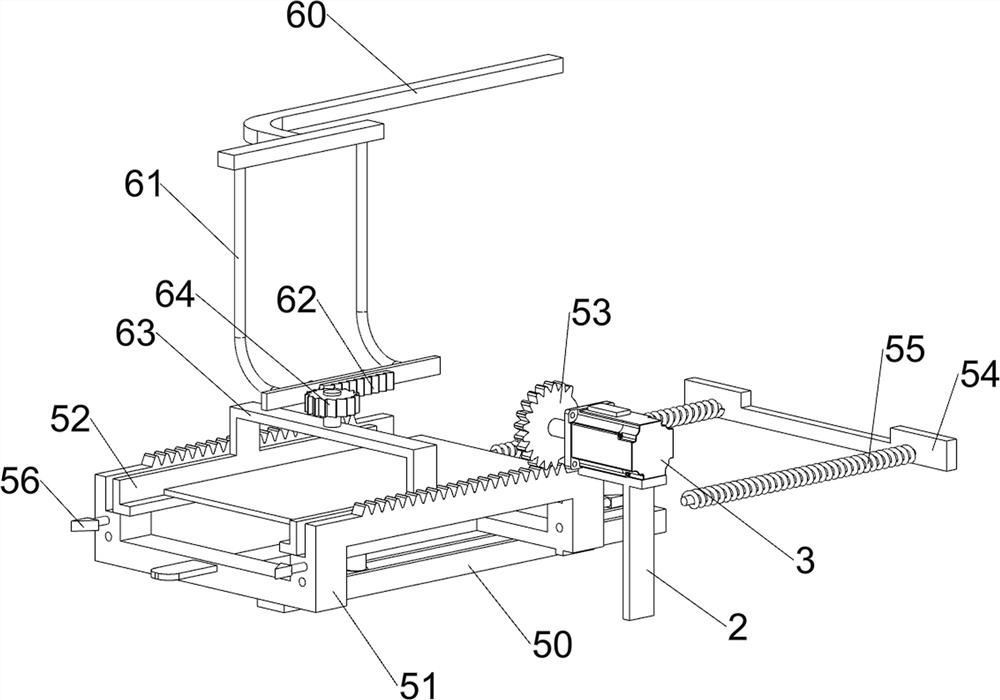

[0024] A kind of pull ring forming equipment for pop cans, such as figure 1 As shown, it includes a base 1, a support base 2, a servo motor 3, a stamping mechanism 4, a propulsion mechanism 5, a rotating mechanism 6 and an extrusion mechanism 7. There is a servo motor 3, the upper right side of the base 1 is provided with a stamping mechanism 4, the upper part of the base 1 is provided with a propulsion mechanism 5, the propulsion mechanism 5 is provided with a rotating mechanism 6, and the stamping mechanism 4 is provided with an extrusion mechanism 7.

[0025] When the user needs to make the pull ring of the pop can, this device can be used. First, the iron sheet to be made of the pull ring is placed on the propulsion mechanism 5, and then the servo motor 3 is turned on, and the servo motor 3 drives the propulsion mechanism 5 to move to the right, and the The iron sheet moves to the bottom of the stamping mechanism 4, and a part of the iron sheet is stamped by the stamping m...

Embodiment 2

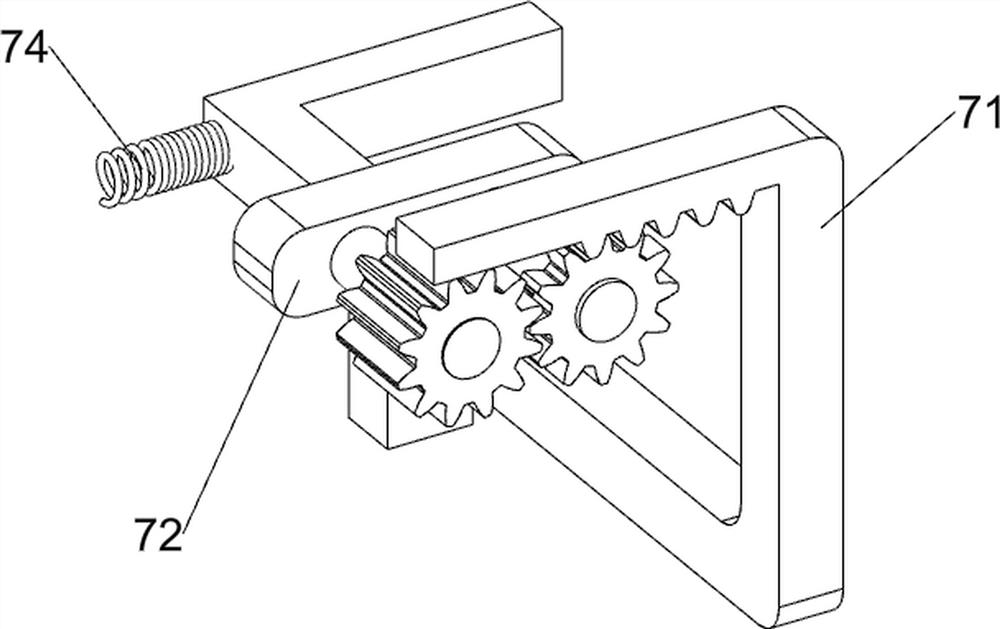

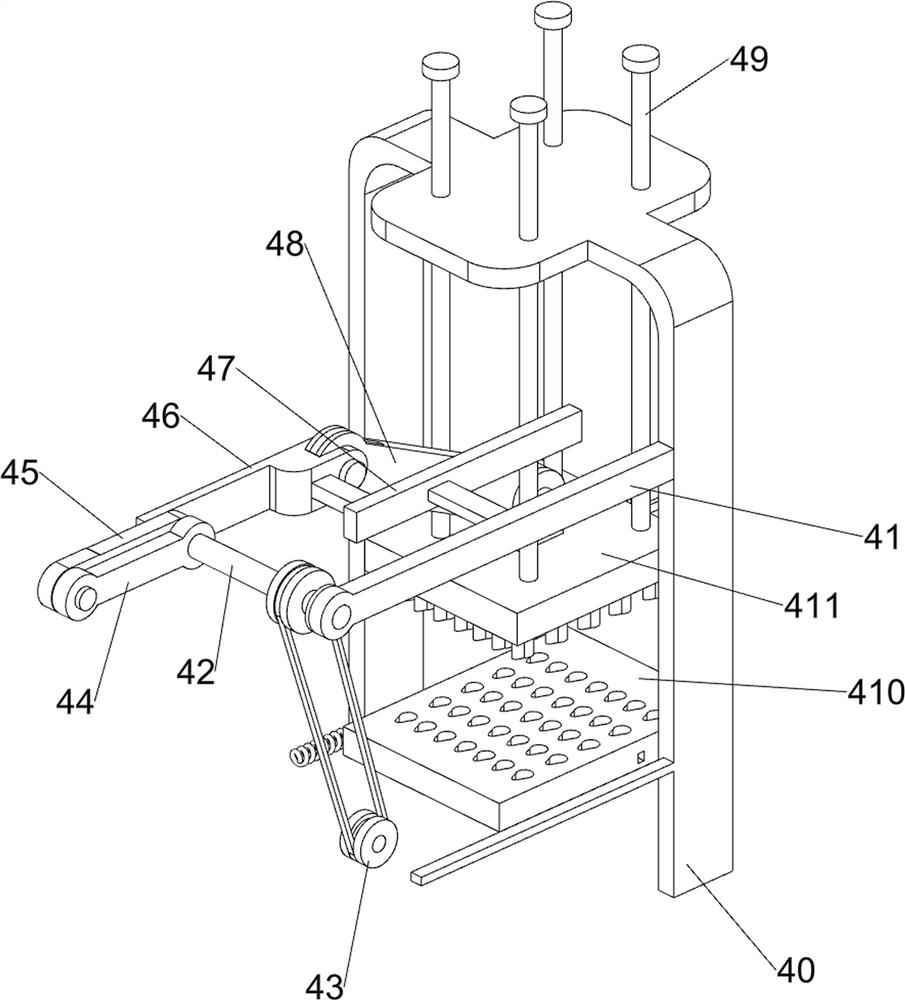

[0027] On the basis of Example 1, such as figure 2 , image 3 , Figure 4 with Figure 5 As shown, the stamping mechanism 4 includes a first fixed frame 40, a first bearing seat 41, a first rotating shaft 42, a transmission assembly 43, a first rotating handle 44, a second rotating handle 45, a connecting rod 46, and a first slide rail 47 , rotating rod 48, slide bar 49, stamping plate 410 and lower pressing plate 411, base 1 upper right side is provided with first fixed mount 40, and first fixed mount 40 is connected with support base 2, and first fixed mount 40 front side left side A first bearing seat 41 is provided, and a first rotating shaft 42 is rotatably arranged on the first bearing seat 41. A transmission assembly 43 is connected between the first rotating shaft 42 and the output shaft of the servo motor 3. The rear side of the first rotating shaft 42 is provided with The first rotating handle 44, the first rotating handle 44 is provided with a second rotating ha...

Embodiment 3

[0036] On the basis of Example 2, such as Image 6 As shown, it also includes a third bearing seat 8, a second rotating shaft 9, a slide plate 10 and a torsion spring 11. The left side of the upper part of the base 1 is symmetrically provided with a third bearing seat 8. Between the third bearing seats 8 on both sides The rotary type is provided with a second rotating shaft 9 , a slide plate 10 is arranged on the second rotating shaft 9 , a torsion spring 11 is arranged on the second rotating shaft 9 , and the torsion spring 11 is connected with the third bearing seat 8 .

[0037] After the special-shaped rack 51 moves to the left and rotates half a circle, since the side of the special-shaped rack 51 is provided with a bump, the bump contacts the slide plate 10. In the initial state, the slide plate 10 is in a vertical state, and the bump moves to the left. And promote the bottom of slide plate 10, make the top of slide plate 10 turn to the right, at this moment, torsion spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com