Modified medical stone filter material for treating ammonia-nitrogen industrial wastewater and preparation method of modified medical stone filter material

A technology of industrial wastewater and medical stone, which is applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of limited removal capacity and unsatisfactory effect of modification technology, so as to improve the removal capacity , No secondary pollution, increase the effect of surface active groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

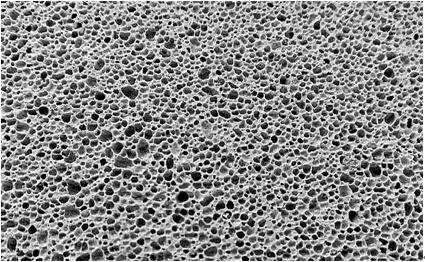

Image

Examples

Embodiment 1

[0033] a. Wash the medical stone with an average particle size of 1.1mm with deionized water, add 0.1mol / L hydrochloric acid solution, the mass ratio of medical stone and hydrochloric acid solution is 1:7; soak for 2h, filter out Washing with deionized water several times to obtain acid-treated medical stone;

[0034] b. Add the acid-treated medical stone prepared in step a into the mixed solution composed of carboxymethyl chitosan, sodium alginate and water, heat and stir, the temperature is 70°C, the stirring speed is 560r / min, the time 4h; after the end, filter out to obtain medical stone with surface active groups; wherein, 34 parts by weight of medical stone, 14 parts by weight of carboxymethyl chitosan, 2 parts by weight of sodium alginate, and 100 parts by weight of water ;

[0035] c, according to the mass ratio of medical stone with active groups on the surface, sodium hydroxide solution is 1:7, the medical stone with surface active group that step b makes is added t...

Embodiment 2

[0037] a. Wash the medical stone with an average particle size of 0.8mm with deionized water, add 0.1mol / L hydrochloric acid solution, the mass ratio of medical stone and hydrochloric acid solution is 1:5; soak for 1h, filter out Washing with deionized water several times to obtain acid-treated medical stone;

[0038] b. Add the acid-treated medical stone prepared in step a into the mixed solution composed of carboxymethyl chitosan, sodium alginate and water, heat and stir, the temperature is 50°C, the stirring speed is 500r / min, the time 5h; after the end, filter out to obtain medical stone with surface active groups; wherein, 30 parts by weight of medical stone, 10 parts by weight of carboxymethyl chitosan, 1 part by weight of sodium alginate, and 120 parts by weight of water share;

[0039] c, according to the mass ratio of medical stone with surface active group, sodium hydroxide solution is 1:5, the medical stone with surface active group that step b makes is added the s...

Embodiment 3

[0041] a. Wash the medical stone with an average particle size of 1.2mm with deionized water, add 0.1mol / L hydrochloric acid solution, the mass ratio of medical stone and hydrochloric acid solution is 1: 10, soak for 3h, filter out Washing with deionized water several times to obtain acid-treated medical stone;

[0042] b. Add the acid-treated medical stone prepared in step a into the mixed solution composed of carboxymethyl chitosan, sodium alginate and water, heat and stir, the temperature is 90°C, the stirring speed is 600r / min, the time 3h; filter out after the end, and obtain medical stone with surface active groups; wherein, 40 parts by weight of medical stone, 20 parts by weight of carboxymethyl chitosan, 3 parts by weight of sodium alginate, 120 parts by weight of water ;

[0043] C, according to the mass ratio of medical stone with surface active group, sodium hydroxide solution is 1: 10, the medical stone with surface active group that step b makes is added the sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com