Wide-temperature-range high-performance primary lithium-manganese battery and preparation method thereof

A lithium-manganese battery, high-performance technology, applied in the field of wide-temperature high-performance primary lithium-manganese battery and its preparation, can solve the problems of easy volatilization of electrolyte, poor fluidity of electrolyte, fracture, etc., to improve electrochemical performance and improve discharge Performance, the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

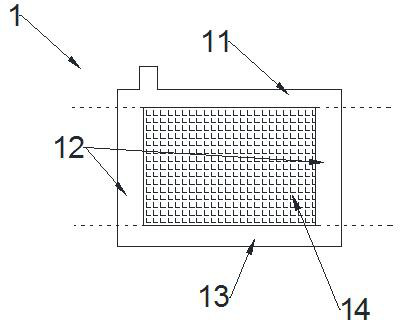

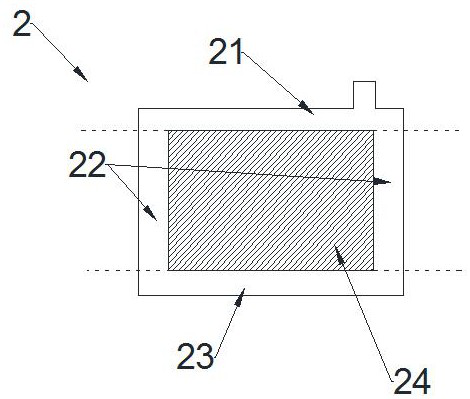

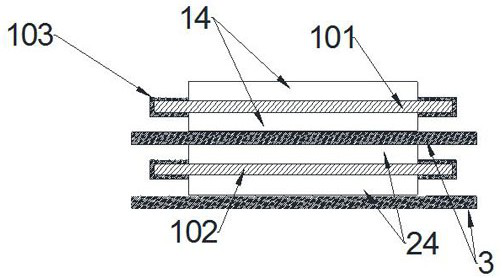

[0046] Such as Figure 1 to Figure 4 As shown, a lithium-manganese battery with wide temperature and high performance is applied in a temperature environment from -50°C to 75°C. The lithium-manganese battery includes a positive electrode sheet 1, a negative electrode sheet 2, a ceramic separator 3, an electrolyte, and a battery case 4. The positive electrode sheet 1, the ceramic diaphragm 3, the negative electrode sheet 2, and the ceramic diaphragm 3 are laminated in sequence to form a dry cell. The lithium-manganese battery is made by putting the dry cell into the battery case 4 and injecting electrolyte, aging, sealing, and aging. , the positiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com