One-way valve fault diagnosis method based on total variation noise reduction and RQA

A fault diagnosis and total variation technology, applied in mechanical valve testing, pattern recognition in signals, instruments, etc., can solve the problem of difficulty in accurately extracting equipment operating state characteristics, harsh working environment of high-pressure diaphragm pumps, and background of check valve vibration signals. noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

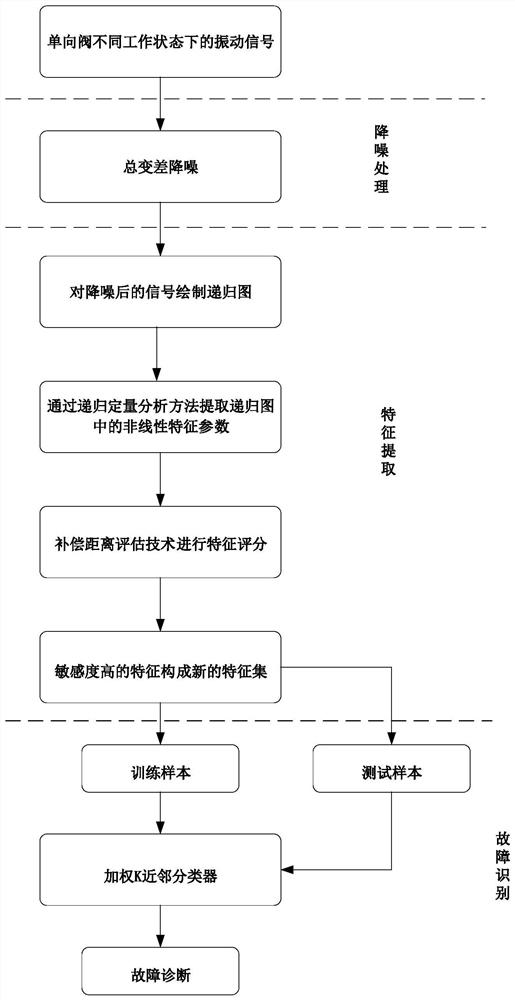

[0087] Embodiment 1: as figure 1 As shown, a check valve fault diagnosis method based on total variation noise reduction and RQA, the specific steps are:

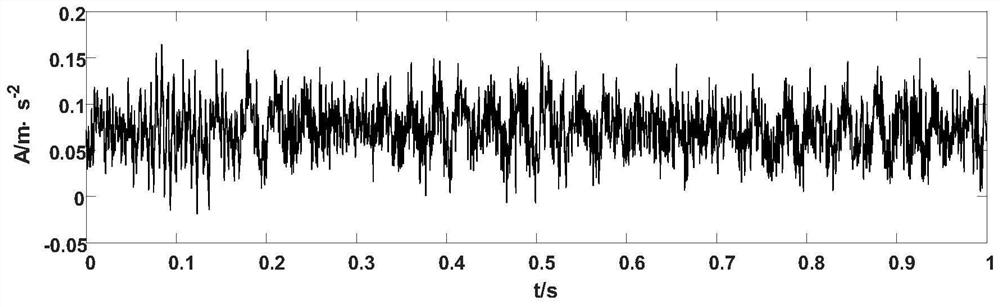

[0088] Step1: Use the acceleration sensor to sample when the check valve is normal, the valve is stuck, and the wear is faulty, and the vibration data of the check valve in each state is obtained.

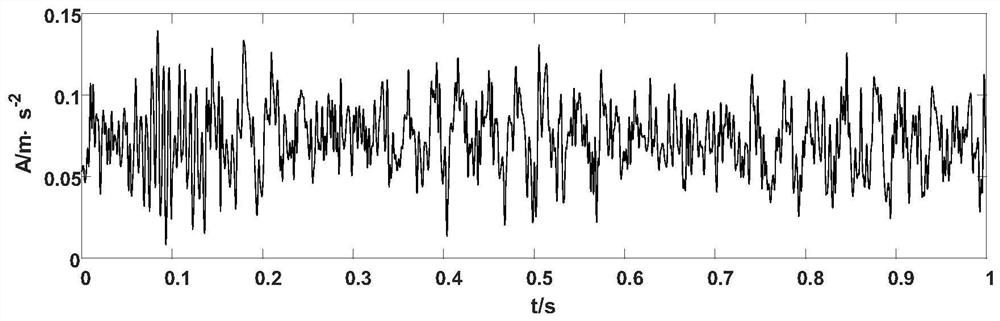

[0089] Step2: Use the total variation noise reduction algorithm to perform noise reduction processing on the data samples in the three states of the check valve.

[0090] Step3: Draw the recursive graphs for the denoised signals, and extract the characteristic parameters in the recursive graphs through recursive quantitative analysis to form a eigenvector matrix.

[0091] Step4: The feature matrix is normalized, and the compensation distance evaluation technology is used for feature scoring to obtain the sensitivity evaluation of each feature, and the features with high sensitivity form a new feature set.

[0092] Step5: Ran...

Embodiment 2

[0108] Embodiment 2: In order to reflect the superiority of the processing method of the present invention, the necessity of denoising the signal and then extracting features and the superiority of RQA in fault feature extraction, the RQA feature is directly extracted from the non-noise-reduced signal to form a feature vector . After the signal is denoised, 12 traditional time-domain statistical features (peak-to-peak value, root mean square, variance and kurtosis indicators, etc.) are extracted to form a feature vector. Then, the above two groups of feature vectors are selected through the compensation distance evaluation technique to select two features with good fault representation and input them into the weighted KNN classifier for comparison. The settings of the weighted KNN classifier and the number of repeated experiments are consistent with those in this paper. Table 5 is the comparison of fault diagnosis results in different situations. The comprehensive results sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com