A noise detection method for rotating machinery monitoring data based on SES-LOF

A technology for rotating machinery and monitoring data, applied in the field of noise detection of rotating machinery monitoring data based on SES-LOF, can solve the problems of monitoring data quality not rising but falling, destroying typical fault information, etc., and achieving the effect of solving the problem of misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

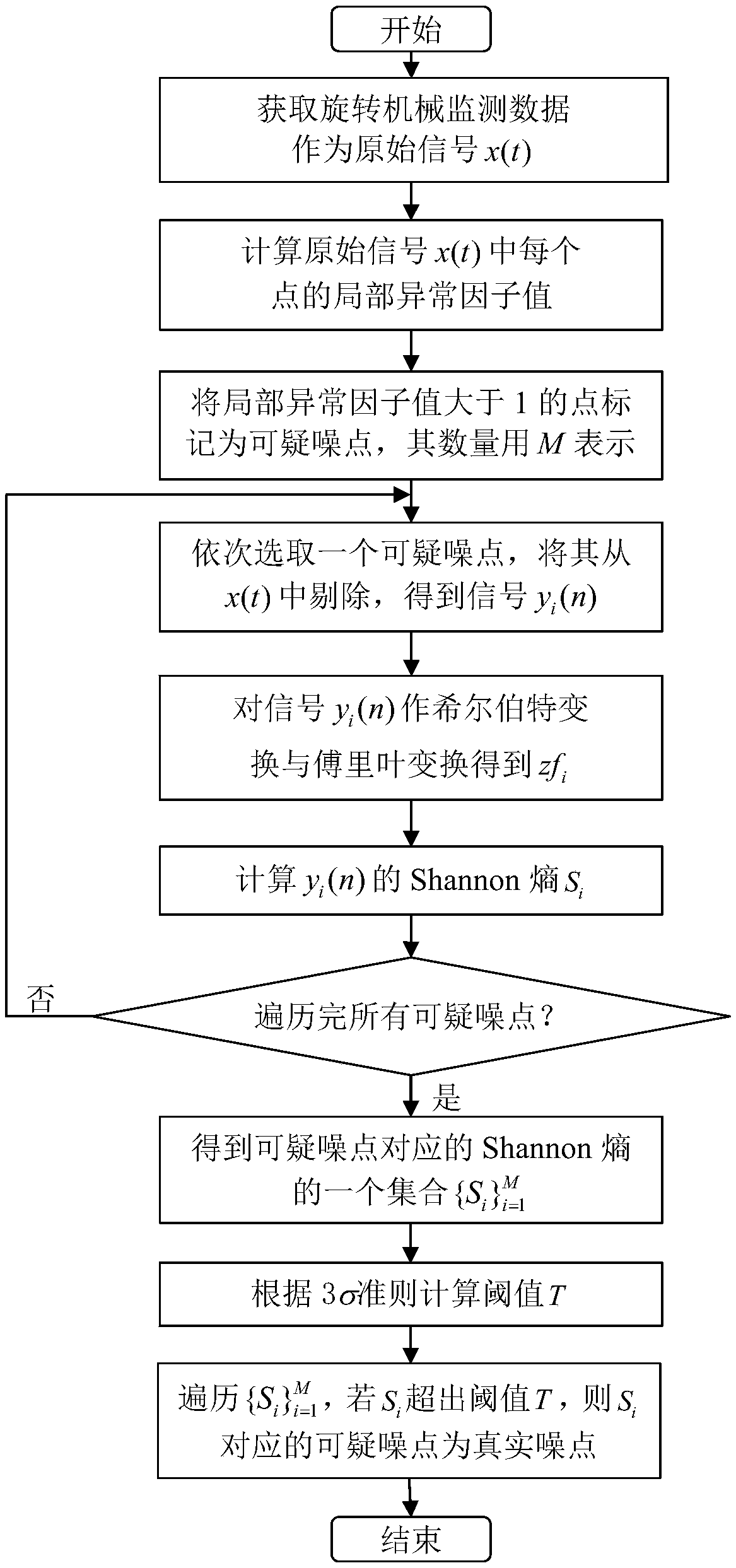

[0034] Such as figure 1 As shown, a SES-LOF-based noise detection method for rotating machinery monitoring data includes the following steps:

[0035] 1) Obtain a segment of rotating machinery monitoring signal as the original signal x(t), where t=1,...,N, N is the number of sampling points of the segment signal; according to the magnitude, the original signal x(t) data segment is calculated sequentially The local outlier factor value of each point in ; specifically, when t=j, the calculation expression of the local outlier factor value of point x(j) is as follows:

[0036]

[0037] Among them, k is a parameter of the LOF algorithm, and its value is taken as 5;

[0038] N k (x(j)) is the neighborhood of point x(j), that is, all points within the kth distance of x(j), including points on the kth distance;

[0039] lrd k (o) with lrd k (x(j)) are the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com