Fiber laying process parameter model construction method and system based on imitation learning

A technology of fiber placement process and process parameters, which is applied in general control systems, control/adjustment systems, instruments, etc., can solve the problems of poor parameter promotion and generalization capabilities, and low control accuracy of process parameters, so as to achieve automatic fiber placement The effect of quality, improved intelligence, and enhanced generalization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with accompanying drawing.

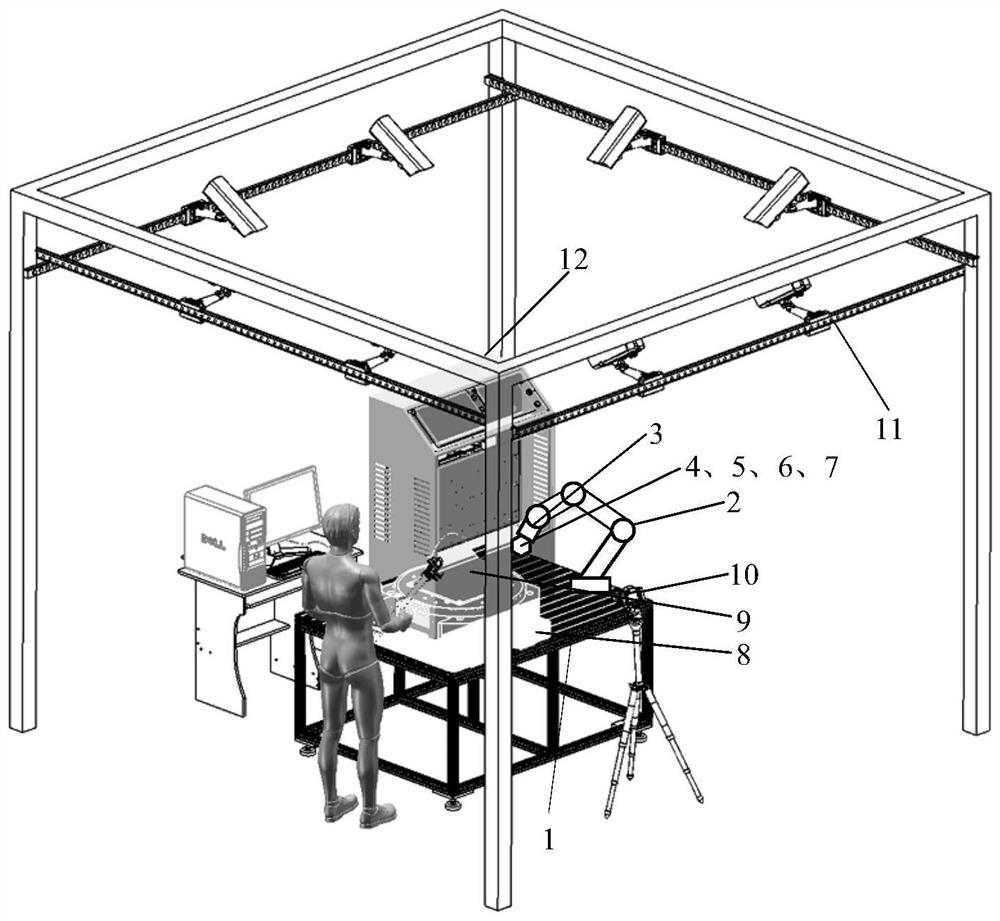

[0046] figure 1 It is a diagram of the system structure involved in the present invention, mainly including: the platform base 1 is used as the installation base of the whole system laying system, the cooperative robot arm 2 and the mold rotating table 8 are installed and fixed on the platform base 1; the curved surface The mold 9 is installed on the mold rotary table 8; the sensing modules such as the tension sensor 5, the rotary encoder 6, and the thermal imager 7 are installed on the designed fiber placement head 4 device; the fiber placement head 4, six-dimensional force / torque The sensor 3 and the cooperative robot arm 2 are installed in sequence to form an automatic fiber laying device;

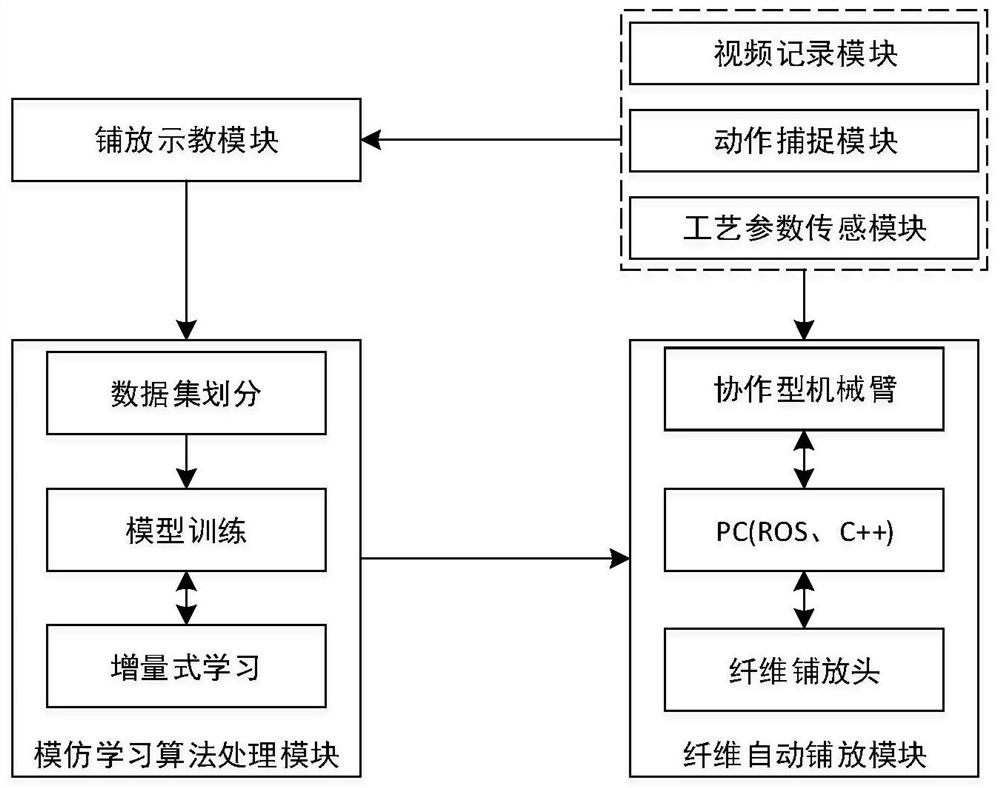

[0047] figure 2 It is a block diagram of the system composition involved in the present invention, including a main body and a control unit for controlling the main body; the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com