Method for ultrasonically and synchronously measuring axial force and shearing force of bolt

A technology of synchronous measurement and shearing force, applied in the direction of measuring torque/torsion force, measuring device, force/torque/power measuring instrument, etc. during tightening, to achieve low cost, improve calibration accuracy, and improve measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

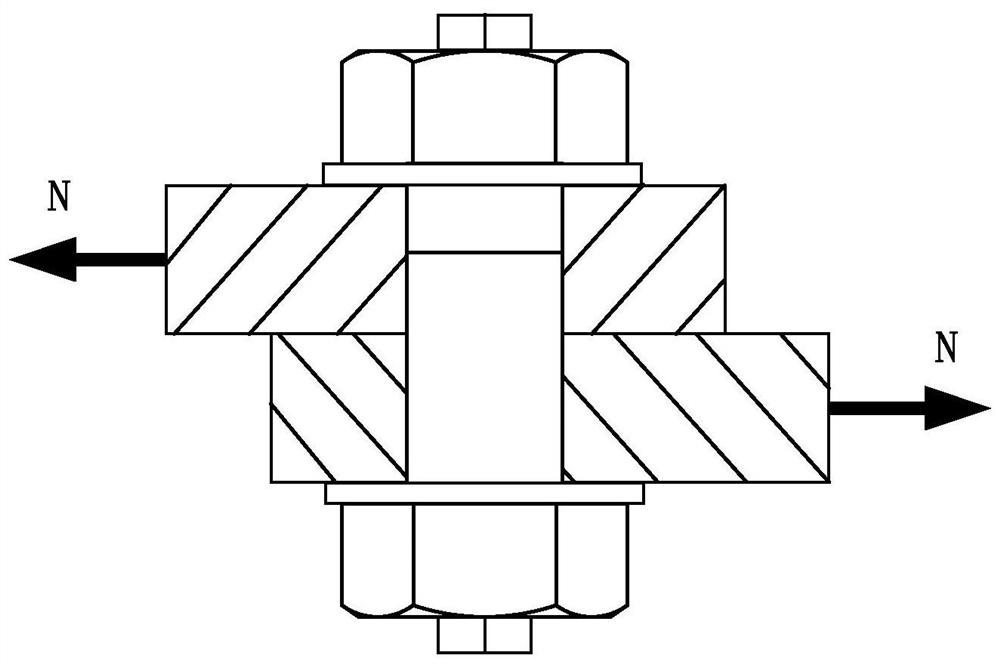

[0042] A method for ultrasonic simultaneous measurement of bolt axial force and shear force, comprising the following steps:

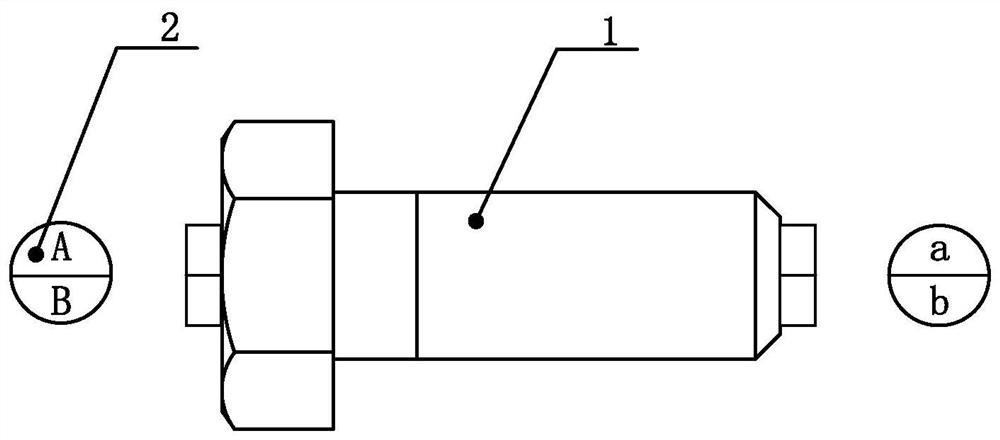

[0043] Step 1: Paste piezoelectric chips on both ends of the bolt to be tested. The piezoelectric chips on each end face are two semicircular concentric piezoelectric chips; the piezoelectric chips on different end faces have the same structure, coaxial and same direction, and the bolt head The upper side of the tail is piezoelectric wafer A, the lower side is piezoelectric wafer B, the upper side of the tail is piezoelectric wafer a, and the lower side is piezoelectric wafer b.

[0044] Before the measurement, the bolts to be tested are polished to meet the surface requirement that the surface roughness is less than 3.2 μm. Paste piezoelectric wafers on the two ends of the bolt, use bolt fastening glue to paste two id...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com