Preparation method of alumina-based water-voltage generator functional area

A generator and alumina technology, which is applied in the fields of hydropower, mechanical equipment, engine components, etc., can solve the problem of difficulty in further improving the power generation efficiency, and achieve the effects of diversified forms, fast water flow, and less structural restrictions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

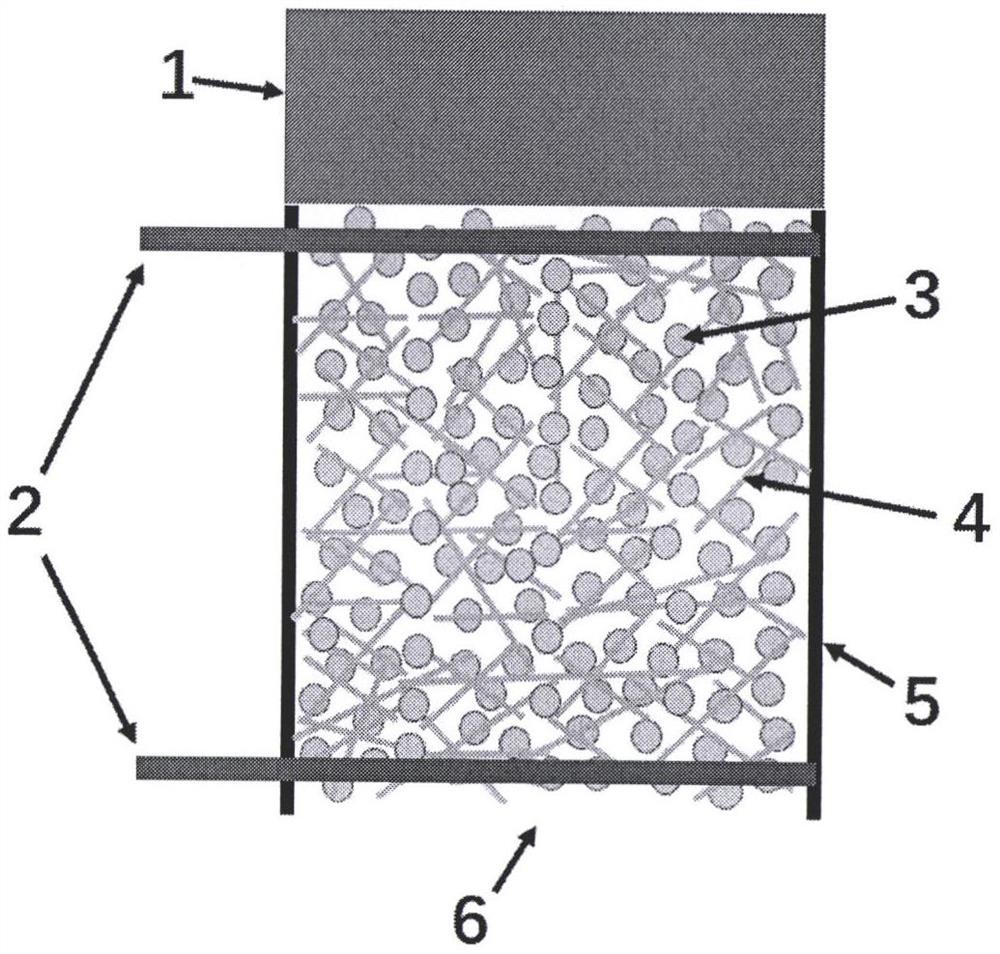

[0028] (1) Mix ethyl cellulose, alumina nanoparticles, alumina nanofibers and absolute ethanol with a mass ratio of 1:10:4:20 and heat and stir at 80°C for 2 hours to obtain Uniform slurry, the average size of alumina nanoparticles is 100nm, the diameter of alumina nanofibers is 20nm, and the length is 20-200μm.

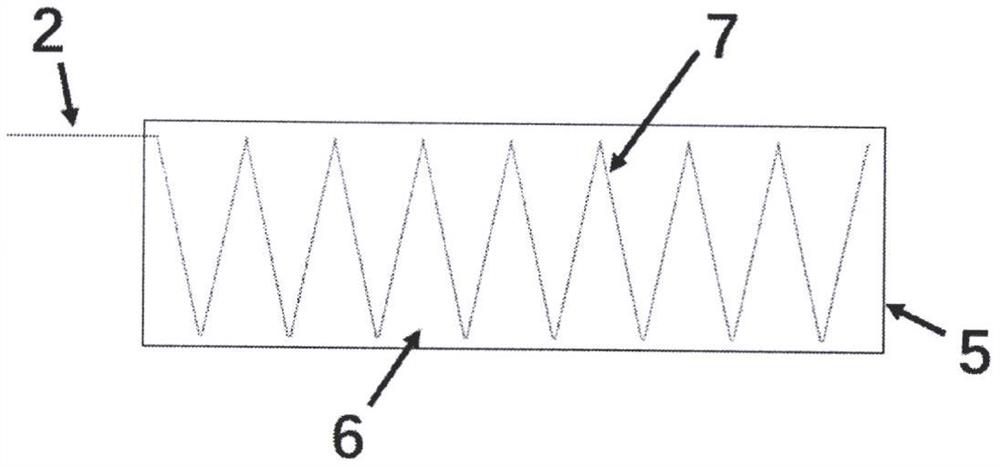

[0029] (2) Put the slurry into a cube-shaped alumina ceramic model with an open top, place and fix graphene-based folded electrodes at both ends, the thickness of the graphene film is 100nm, the electrodes are folded, and the folded electrodes are adjacent The distance between the vertices is 10mm, the overall length and width of the electrode correspond to the internal length and internal width of the alumina ceramic model, and the folded electrode has a lead-out end for electric energy output.

[0030] (3) Put the alumina ceramic model filled with slurry into the muffle furnace, anneal in the air atmosphere, the temperature is 370 ° C, the time is 2 hours, and natu...

Embodiment 2

[0033] (1) Mix ethyl cellulose, alumina nanoparticles, alumina nanofibers and absolute ethanol with a mass ratio of 1:10:4:20 and heat and stir at 80°C for 2 hours to obtain Uniform slurry, the average size of alumina nanoparticles is 100nm, the diameter of alumina nanofibers is 20nm, and the length is 20-200μm.

[0034] (2) Put the slurry into a cube-shaped alumina ceramic model with an open top, place and fix carbon nanotube-based folded electrodes at both ends, the thickness of the graphene film is 100nm, and the electrodes are folded. The distance between adjacent vertices is 10 mm, the overall length and width of the electrode correspond to the internal length and internal width of the alumina ceramic model, and the folded electrode has a lead-out end for electric energy output.

[0035] (3) Put the alumina ceramic model filled with slurry into the muffle furnace, anneal in the air atmosphere, the temperature is 370 ° C, the time is 2 hours, and naturally cool to room tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com