A method of pigging for remote pneumatic conveying pipelines

A pneumatic conveying pipeline and long-distance technology, applied in the direction of conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problems of food and crops deposition, affecting the transportation of food and crops, easy to block pipelines, etc., to improve local force and load The effect of uniform force and reduced friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

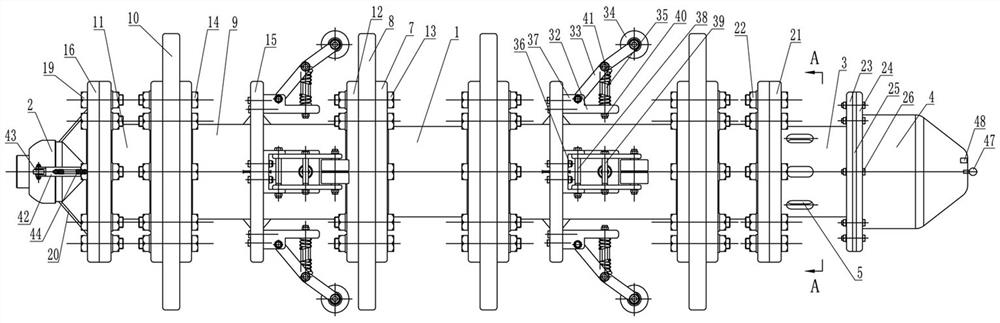

[0040] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0041] like Figure 1-7 As shown, a remote pneumatic conveying pipeline pigging method specifically includes the following steps:

[0042] (1) First, collect data and master various design parameters of remote pneumatic conveying pipelines; design parameters include design bearing pressure, inner diameter, wall thickness, nominal diameter, material and mechanical properties of the pipeline; understand the direction and elevation difference of the pipeline and the distance between the valve chambers in the pigging section; for the remote pneumatic conveying pipelines that have been in operation, it is necessary to collect and analyze the operating parameters of the remote pneumatic conveying pipelines in the near future and the previous cleaning records, so as to formulate a reasonable gas allocation plan and adjust the gas volume in advance preparations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com