Super-wear-resistant heat-preservation soft floor and manufacturing process thereof

A manufacturing process and ultra-wear-resistant technology, applied in the field of plate processing, can solve the problems of impact resistance, poor heat preservation effect, high production cost, etc., to achieve strong impact resistance, good foot feel, and avoid glue opening and deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

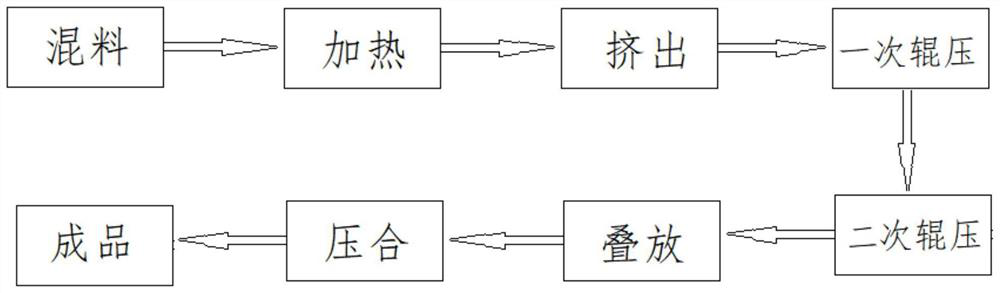

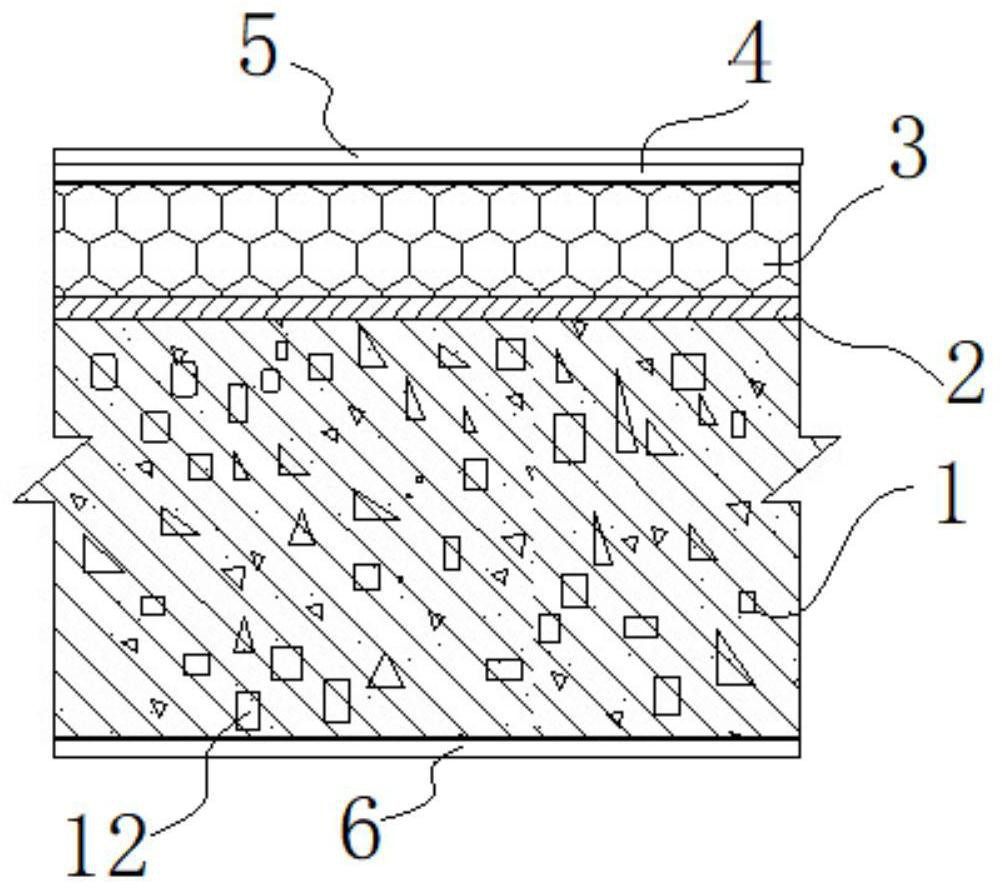

[0041] The production process of the ultra-wear-resistant and heat-preserving soft floor in this embodiment is to add straw segment 12 to the soft substrate 1 component as the slow-release carrier of the glue; , and the balance layer 6, soft substrate 1, cloth fiber layer 2, heat preservation layer 3, decorative layer 4 and wear-resistant layer 5 are stacked in sequence and the glue is slowly released during the process of pressing into a board. Since the hollow structure of the straw section 12 has a good temporary storage function for the glue, it can prevent the glue from contacting with other components prematurely to form a lump and cause uneven mixing. The glue solution is released slowly during the composite process, so that the balance layer 6, the cloth fiber layer 2, and the insulation layer 3 do not need to be dipped or brushed during the composite process, and the cloth fiber layer 2 is made of yarn and aramid fiber. Make full use of the adsorption adhesion ability...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com