Precious metal stirring and mixing device

A technology for mixing and mixing precious metals, which is applied in the direction of mixers, mixer accessories, mixers with rotating containers, etc. It can solve the problems of long length of stirring paddle, impossibility of stirring paddle, easy bending, etc., and achieves long service life. The effect of stirring dead angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

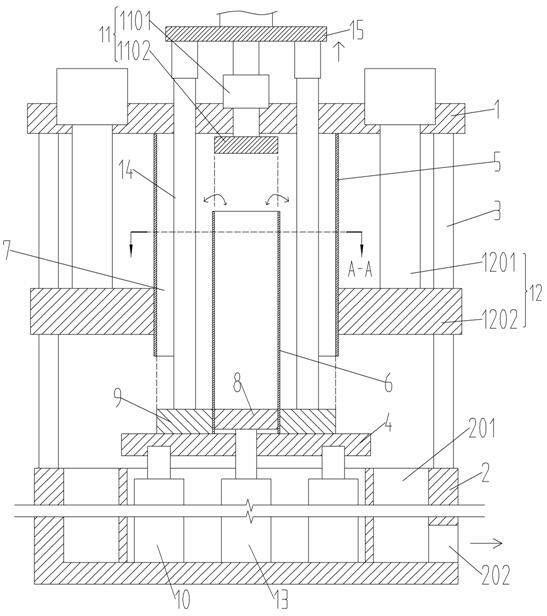

[0026] The embodiment is basically as attached figure 1 and figure 2 Shown: a precious metal stirring and mixing device, including a top cover 1, a storage box 2 and a bottom support plate 4, the cross sections of the top cover 1 and the storage box 2 are circular, and the top cover 1 and the storage box 2 are connected by four The column 3 is connected, the top of the connecting column 3 is welded with the top cover 1, and the bottom of the connecting column 3 is welded with the container 2. The container 2 is provided with an upward-opening, annular discharge cavity 201 , and a discharge port 202 is provided on the side of the container 2 .

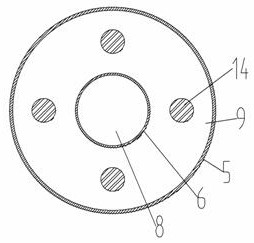

[0027] The lower surface of the top cover 1 is integrally welded with an outer cylinder 5 opening downward, the bottom support plate 4 is located directly below the top cover 1, the upper surface of the bottom support plate 4 is fixedly connected with an inner cylinder 6, and 5 sets of outer cylinders Connected to the outside of the ...

Embodiment 2

[0041] The difference between this embodiment and Embodiment 1 is that: for the convenience of cleaning the inner cylinder 6 , the inner cylinder 6 is placed on the upper surface of the bottom support plate 4 . The lower surface of the inner cylinder 6 is limited by a limit ring 9 and a discharge plate 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com