Method and device for slitting and using tobacco leaves and tobacco product

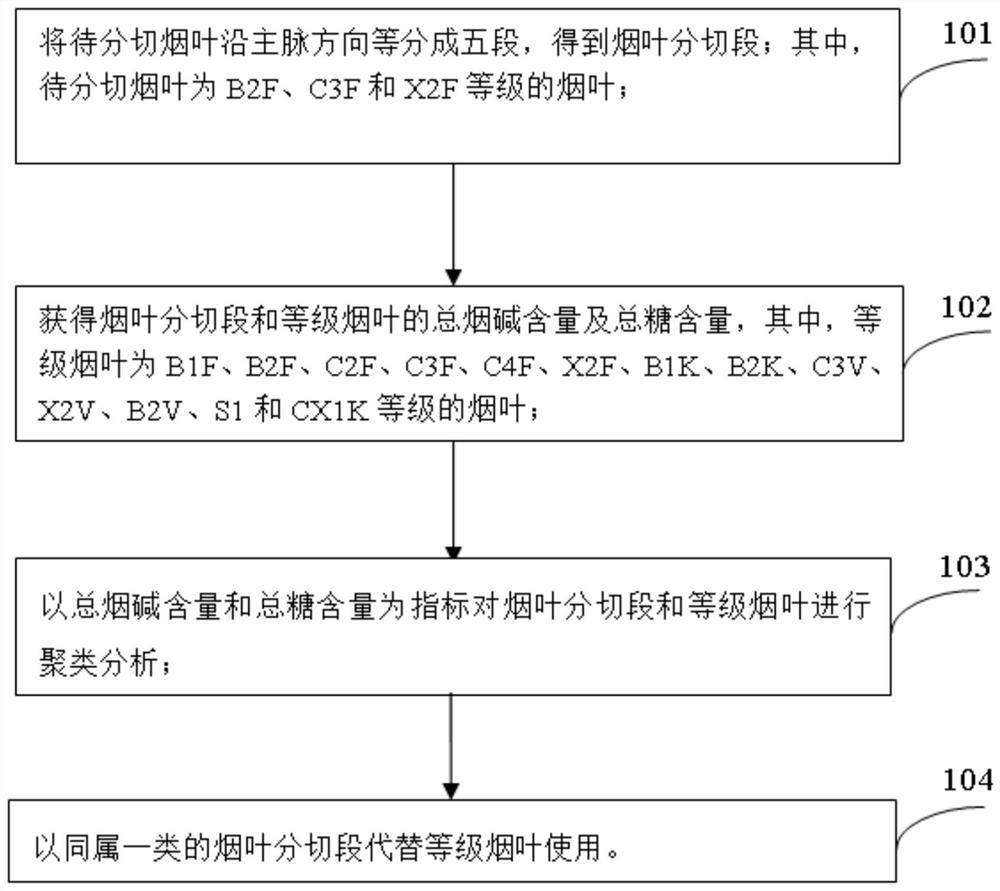

A technology for tobacco products and tobacco leaves, applied in the field of tobacco, can solve the problems of difficult operation, different compatibility, insufficient tobacco leaf raw materials, etc., and achieve the effects of simple cutting operation, improved stability, and stable overall sensory quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] The cutting and use of embodiment 1 tobacco leaves

[0094] Take Yunnan Baoshan Yun 116 varieties of fragrant tobacco leaves acquired in 2019, and grade the tobacco leaves according to the national standard GB2635-92 after initial roasting to obtain B1F, B2F, C2F, C3F, C4F, X2F, B1K, B2K, C3V, X2V, B2V, S1, CX1K grade tobacco leaves.

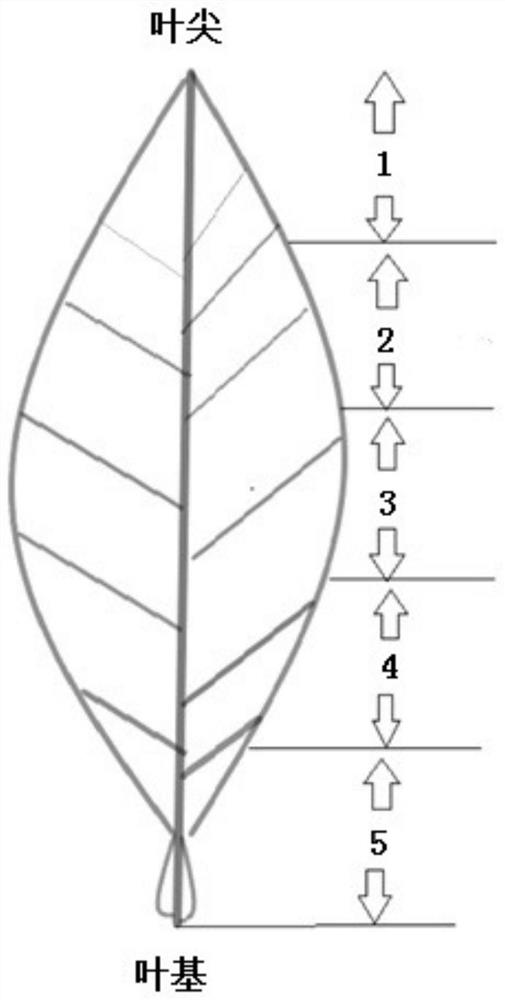

[0095] Pretreatment: Take some complete leaves of B2F, C3F and X2F grade tobacco leaves, according to the image 3 As shown, each tobacco leaf is equally divided into five sections along the direction of the main vein, and each section has the same width; wherein, the cutting sections of B2F grade tobacco leaves from the tip to the base are marked as B-1 and B-2. , B-3, B-4, B-5, C3F grade tobacco leaves from the leaf tip to the leaf base are marked as C-1, C-2, C-3, C-4, C-5 in turn, The cutting sections of X2F grade tobacco leaves from the leaf tip to the leaf base are marked as X-1, X-2, X-3, X-4, and X-5 in turn.

[0096] A conti...

Embodiment 2

[0106] Example 2 Sensory quality evaluation

[0107] Cigarette A1: Mix the cut tobacco of C2F, C3F, X2F, B2F grade tobacco leaves according to the ratio of 3:3:2:2, and make cigarettes according to the conventional method;

[0108] Cigarette A2: Mix X-1 and C-1 in equal proportions and replace the C2F grade tobacco leaves in cigarette A1 in equal proportions. At the same time, mix C-5 and B-1 in equal proportions and then in equal amounts. Instead of the B2F grade tobacco leaves in the cigarette A1, the rest are made into cigarettes in the same way as the cigarette A1.

[0109] The sensory quality of cigarettes A1-A2 was evaluated by 7 professional evaluators of sensory quality using the YC / T 415-2011 standard. The results are shown in Table 3.

[0110] Table 3 Scores of sensory quality of cigarettes A1-A2

[0111] sample Cigarette A1 Cigarette A2 aroma quality 6.6 6.8 Aroma volume 6.9 6.8 Translucent 7.5 7.3 Miscellaneous gas 6.9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com