Variable tension fastening system for vehicle covers

a technology of vehicle covers and tension fasteners, which is applied in the field of fasteners, can solve the problems of insufficient method of attaching canvas tops to vehicles, loss of elasticity of other cover materials, and loss of “stretch” of canvas or other similar covering materials, and achieves the effect of simple and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

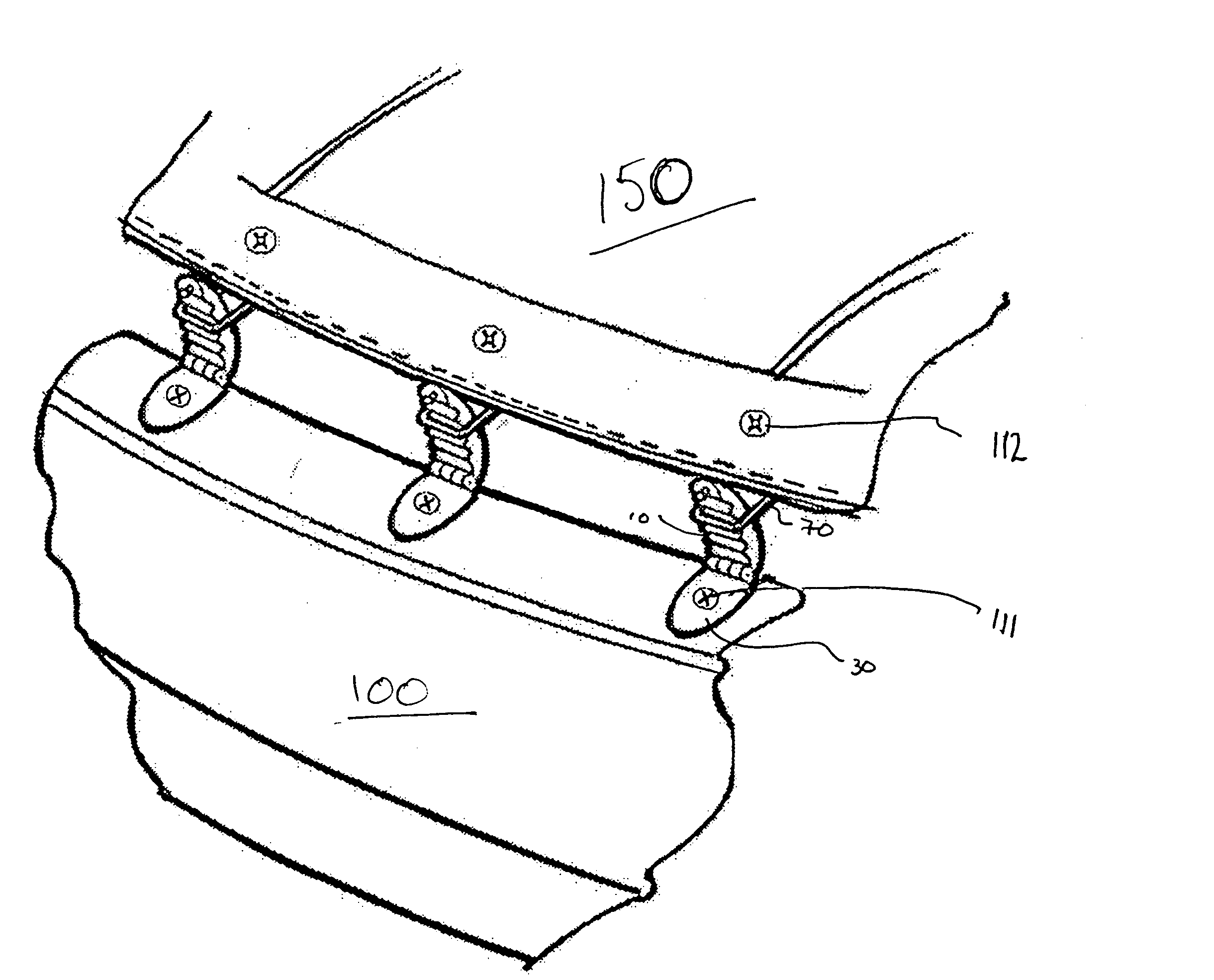

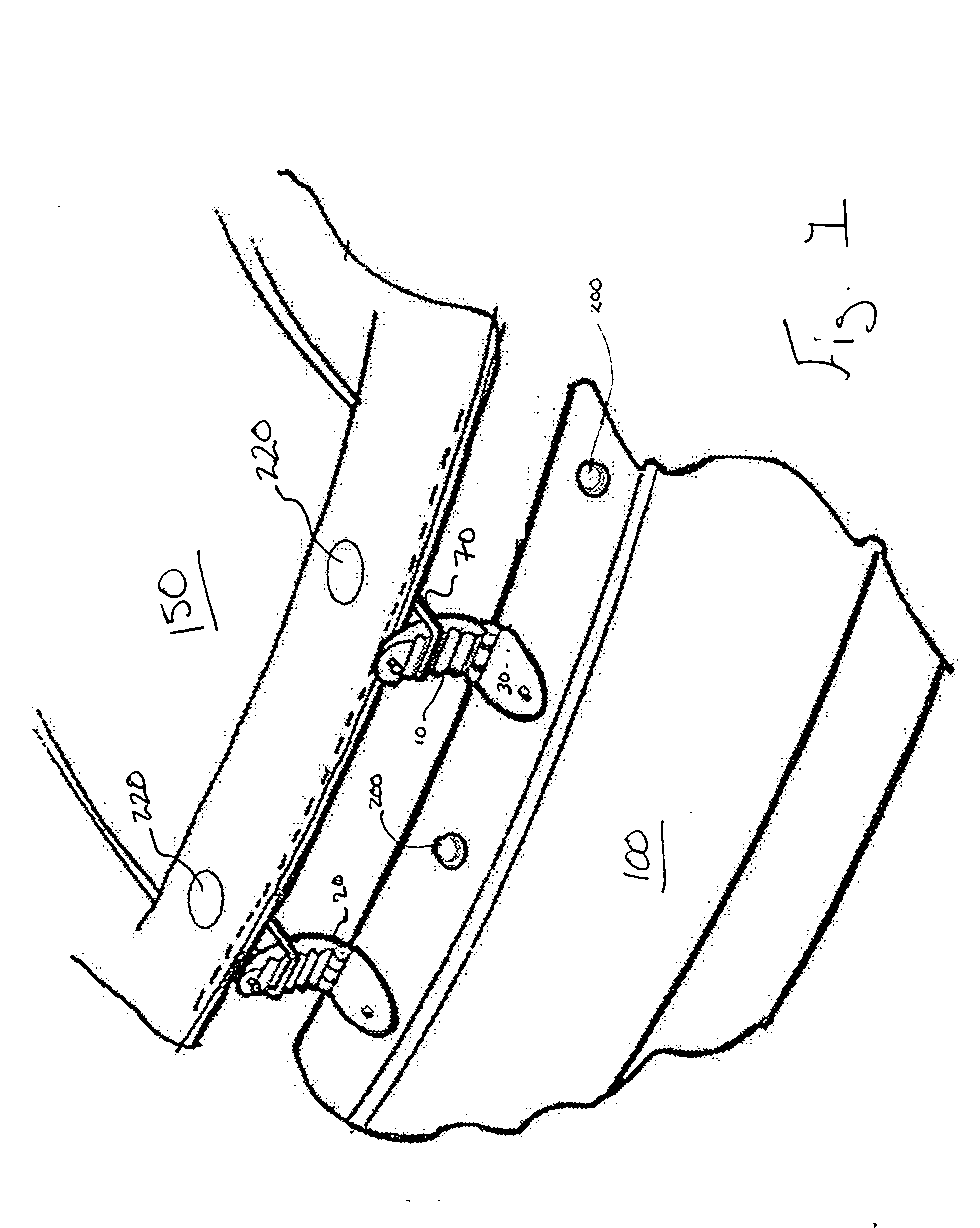

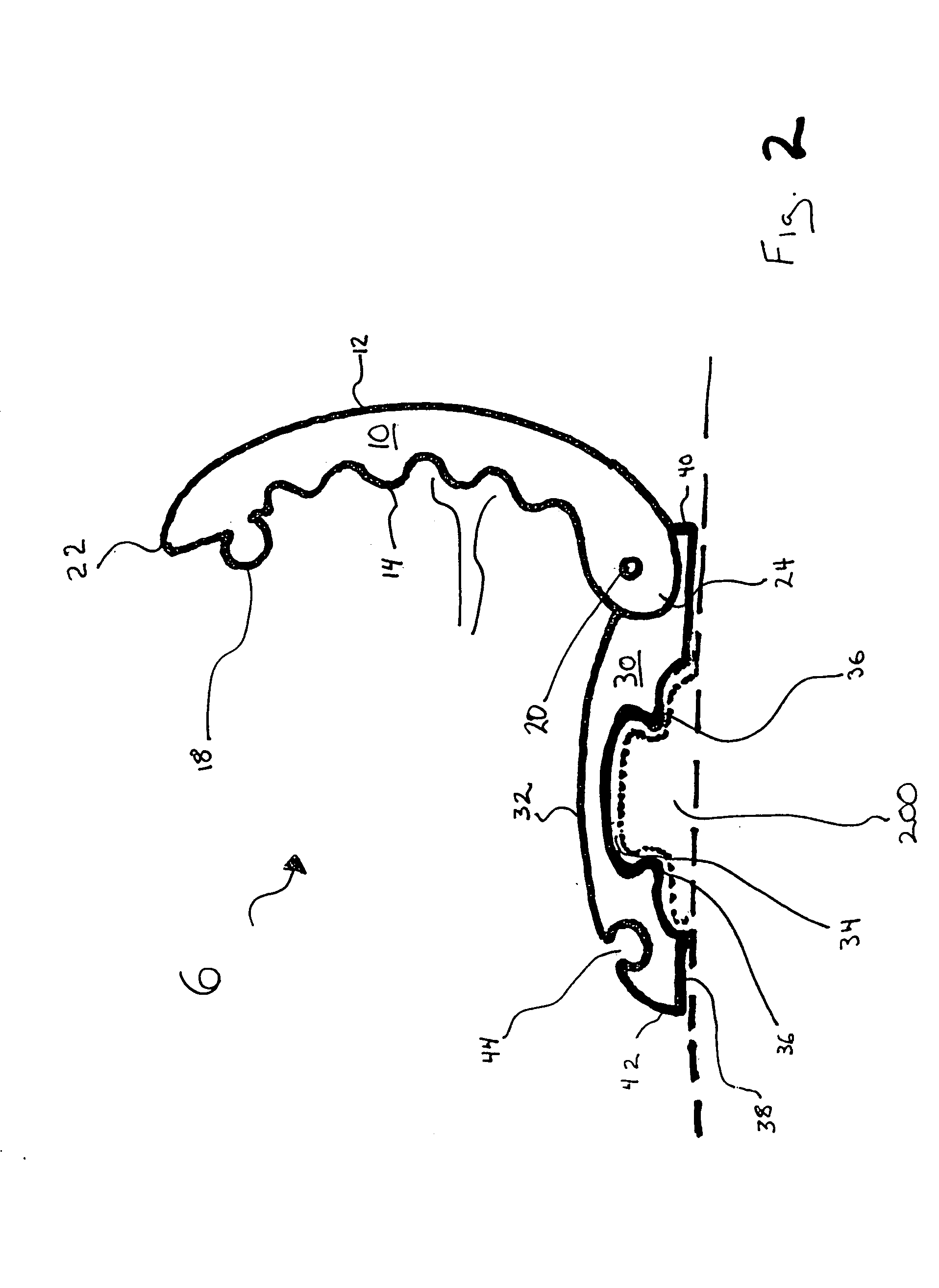

[0024] With reference to the drawings, the fastening device of the present invention according to a preferred embodiment includes a two piece fastening system, generally indicated by reference numerals 6 and 8, denoting the first and second portions of the system, respectively. As illustrated, the embodiments are directed to the specific example of a marine vehicle or craft such as a boat. It will be understood by those skilled in the art that such fastening system as described herein may also be utilized on other types of vehicles, such as open deck vehicles. Such vehicle types may include, but are not limited to boats, trucks, jeeps or other vehicles having an area which is adapted to be covered or enclosed by a covering material. For example the bed of a pick-up truck is typically covered by a canvas or other suitable covering material which is fastened and tensioned to the sides. Jeeps or other SUV types of vehicles also may include a “soft cover” which is fastened and tensioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com