Drag-and-drop photoelectric composite cable and production process for aboveground mining engineering

A photoelectric composite and production process technology, applied in the direction of double-stranded/quad-stranded cable, communication cable, insulated cable, etc., can solve the problem of short mechanical life of the cable, achieve good shielding reliability, strengthen Mechanical strength, good bending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

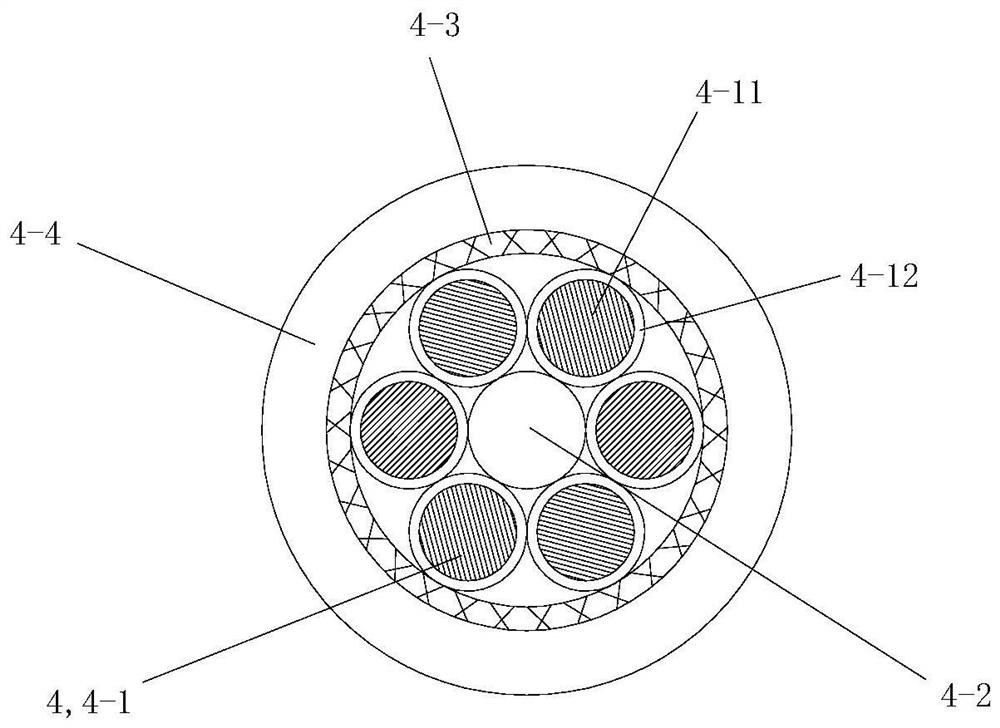

[0060] See figure 1 , The towing photoelectric composite cable for ground mining engineering of the present invention includes a main core 1, a monitoring core 2, a center filling 3, a control core 4, an optical cable 5, a ground core 6, a reinforcing layer 7 and an outer sheath 8.

[0061] See figure 1 , there are three main cores 1, and the three main cores 1 have the same structure, and are provided with a main core conductor 1-1, a main core insulating layer 1-2 and a shielding layer sequentially along their respective radial directions from inside to outside.

[0062] The main core conductor 1-1 is formed by twisting and re-twisting several tinned copper wire bundles. The main core insulating layer 1-2 is made by continuous vulcanization of ethylene-propylene rubber with a hardness of 60A to 80A, and the main core insulating layer 1-2 is extruded outside the main core conductor 1-1.

[0063] See figure 1 , the shielding layer includes a braided shielding layer 1-31 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com