High-voltage direct-current contactor

A high-voltage DC, contactor technology, applied in relays, electrodeless relays, electromagnetic relays, etc., can solve the problems of low protection level, no self-cleaning ability of contacts, complex structure, etc. The effect of gate triggering time and simple contact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further described as follows in conjunction with accompanying drawing and embodiment:

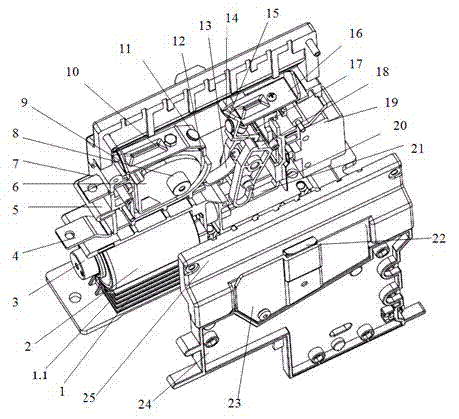

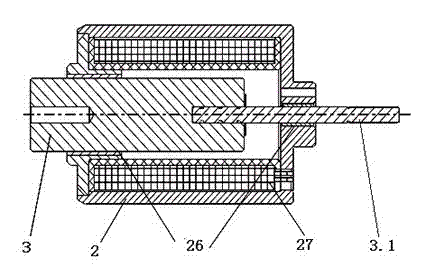

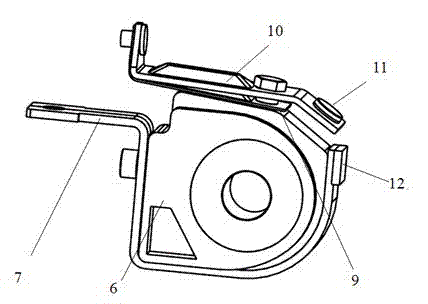

[0032] Such as Figure 1 ~ Figure 4 Shown: a high-voltage DC contactor, which has an organic body part, an electromagnetic drive part, a transmission part and a magnetic blow part, as well as auxiliary contacts 19, and an arc extinguishing chamber 25; wherein: the body part has a base 1, a main frame 5, The main frame cover plate 24, the dynamic arc striking angle 16 installed on the main frame 5 and the lower connecting copper bar 4; the main frame 5 is the positioning reference of the entire contactor transmission part, and the main frame cover plate 24 is inlaid and assembled to form a body part; the electromagnetic driving part has a cylindrical yoke 2, a moving iron core 3 and a coil 27; the electromagnetic driving part is installed horizontally on the base 1 provided with a cooling fin 1.1; the transmission part has a pusher connected with the moving ir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com