Hardened cement water cement ratio prediction method and system based on cement microstructure image

A microstructure and water-cement ratio technology, applied in image analysis, image enhancement, image data processing, etc., can solve problems such as unavoidable errors and complicated processes, and achieve the effects of improving understanding, good real-time performance, and improving estimation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

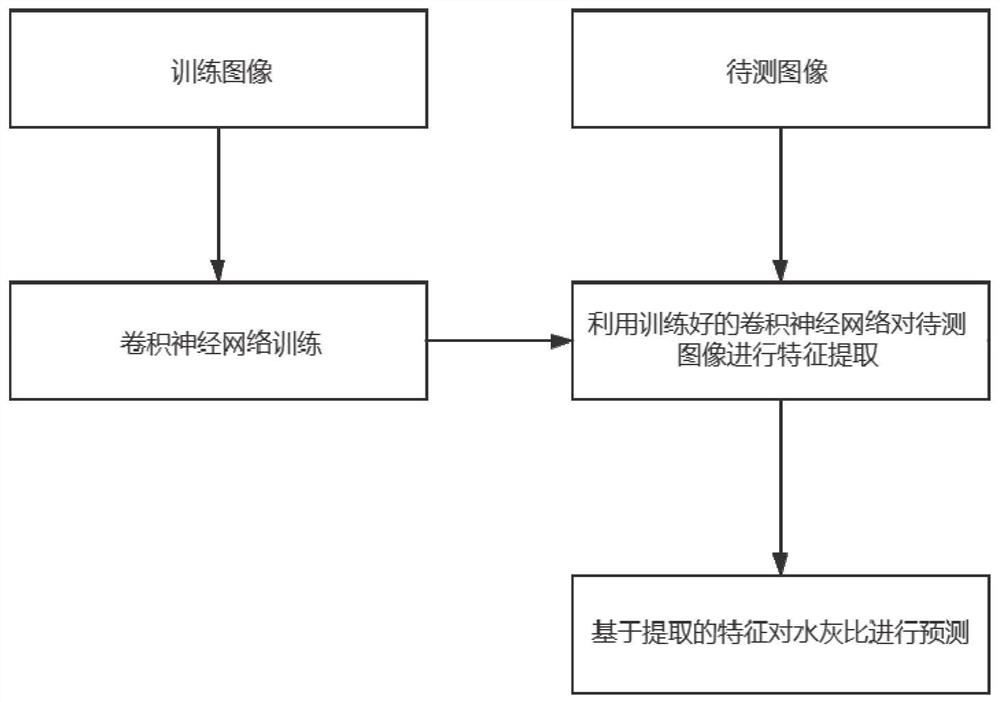

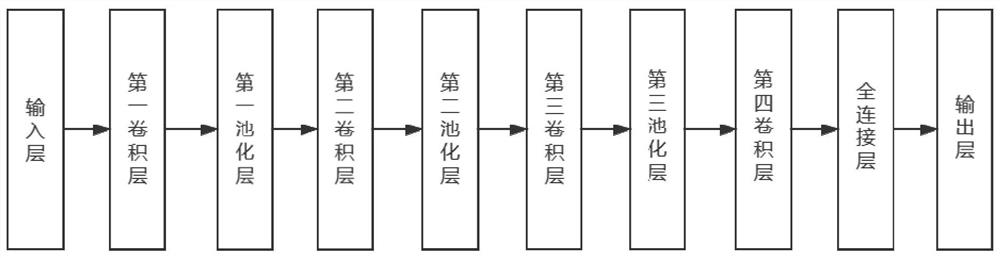

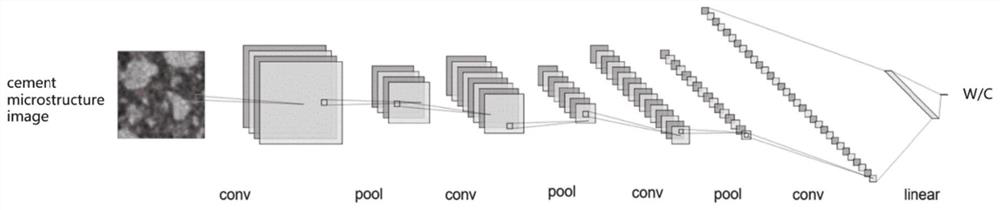

[0036]This embodiment provides a method for predicting the water-cement ratio of hardened cement based on cement microstructure images;

[0037]The prediction method of hardened cement water-cement ratio based on cement microstructure image includes:

[0038]S101: Obtain a cement image to be predicted;

[0039]S102: preprocessing the cement image to be predicted;

[0040]S103: Input the pre-processed cement image to be predicted into the pre-trained convolutional neural network; output the predicted value of the water-cement ratio of the cement image to be predicted.

[0041]As one or more embodiments, the S101: acquiring a cement image to be predicted; refers to acquiring images of different angles of the hardened cement to be predicted at the same resolution.

[0042]As one or more embodiments, the S102: preprocessing the cement image to be predicted; the specific steps include:

[0043]Standardize the image processing and image cutting processing.

[0044]As one or more embodiments, the S103: input the ...

Embodiment 2

[0111]This embodiment provides a hardened cement water-cement ratio prediction system based on cement microstructure images;

[0112]The water-cement ratio prediction system of hardened cement based on cement microstructure image, including:

[0113]The obtaining module is configured to: obtain the cement image to be predicted;

[0114]A preprocessing module, which is configured to: preprocess the cement image to be predicted;

[0115]The prediction module is configured to: input the pre-processed cement image to be predicted into a pre-trained convolutional neural network; and output the predicted value of the water-cement ratio of the cement image to be predicted.

[0116]It should be noted here that the above-mentioned acquisition module, pre-processing module, and prediction module correspond to steps S101 to S103 in Embodiment 1. The above-mentioned modules and corresponding steps implement the same examples and application scenarios, but are not limited to the above-mentioned embodiments. On...

Embodiment 3

[0120]This embodiment also provides an electronic device, including: one or more processors, one or more memories, and one or more computer programs; wherein, the processor is connected to the memory, and the above one or more computer programs are It is stored in a memory, and when the electronic device is running, the processor executes one or more computer programs stored in the memory, so that the electronic device executes the method described in the first embodiment.

[0121]It should be understood that in this embodiment, the processor may be the central processing unit CPU, the processor may also be other general-purpose processors, digital signal processors DSP, application-specific integrated circuits ASIC, ready-made programmable gate array FPGAs or other programmable logic devices , Discrete gates or transistor logic devices, discrete hardware components, etc. The general-purpose processor may be a microprocessor or the processor may also be any conventional processor or th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com