Ultrafine nanoporous silver sERS substrate material based on (111) plane orientation enrichment and preparation method thereof

A technology of ultra-fine nano and substrate materials, applied in nanotechnology, analytical materials, nanotechnology, etc. for materials and surface science, can solve problems such as inability to obtain enrichment, achieve strong adsorption of molecules, and high specific surface area , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

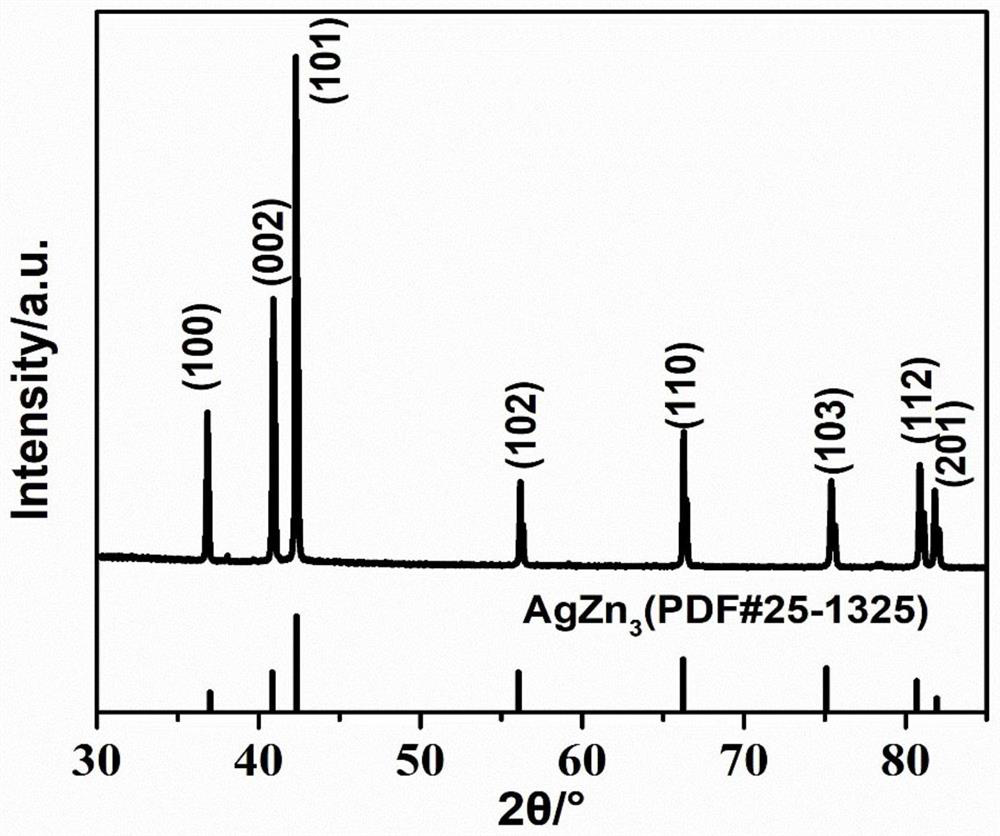

[0040] S1: Weigh Ag and Zn pure metal particles according to the composition ratio of 19.6:80.4, and after mixing, melt into Ag through a high-frequency induction melting furnace under the protection of inert gas 19.6 Zn 80.4 Alloy ingot, the Ag obtained by smelting 19.6 Zn 80.4 The alloy ingot is smelted repeatedly 3-4 times to ensure the uniformity of the internal composition of the ingot.

[0041] Ag was prepared by the single-roll stripping process 19.6 Zn 80.4 alloy strip,

[0042] Put the broken alloy ingot into the quartz tube (diameter ), put it vertically into the induction melting coil of the single-roller stripping device, and reheat the alloy to a molten state through high-frequency induction;

[0043] Introduce high-pressure argon gas into the quartz tube, so that the melt is quickly sprayed to the copper roller with a rotation speed of 1500rpm under the action of pressure, and the melt is rapidly solidified into an alloy thin strip by the chilling effect o...

Embodiment 2

[0046]S1: Weigh Ag and Zn pure metal particles according to the ratio of 23.6:76.4. After mixing, they are smelted into Ag by high-frequency induction melting furnace under the protection of inert gas. 23.6 Zn 76.4 Alloy ingot, the Ag obtained by smelting 23.6 Zn 76.4 The alloy ingot is smelted repeatedly 3-4 times to ensure the uniformity of the internal composition of the ingot.

[0047] Ag was prepared by the single-roll stripping process 23.6 Zn 76.4 Alloy strips, put broken alloy ingots into a quartz tube with a lower opening (diameter ), put it vertically into the induction melting coil of the single-roller stripping device, and reheat the alloy to a molten state through high-frequency induction;

[0048] Introduce high-pressure argon gas into the quartz tube, so that the melt is quickly sprayed to the copper roller with a rotation speed of 1500rpm under the action of pressure, and the melt is rapidly solidified into an alloy thin strip by the chilling effect of th...

Embodiment 3

[0051] S1: Weigh Ag and Zn pure metal particles according to the ratio of composition ratio of 23:77, and after mixing, they are smelted into Ag by high-frequency induction melting furnace under the protection of inert gas 23 Zn 77 Alloy ingot, the Ag obtained by smelting 23 Zn 77 The alloy ingot is smelted repeatedly 3-4 times to ensure the uniformity of the internal composition of the ingot.

[0052] Ag was prepared by the single-roll stripping process 23 Zn 77 Alloy strips, put broken alloy ingots into a quartz tube with a lower opening (diameter ), put it vertically into the induction melting coil of the single-roller stripping device, and reheat the alloy to a molten state through high-frequency induction;

[0053] Introduce high-pressure argon gas into the quartz tube, so that the melt is quickly sprayed to the copper roller with a rotation speed of 1500rpm under the action of pressure, and the melt is rapidly solidified into an alloy thin strip by the chilling eff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com