Method for preparing crude heparin sodium from porcine small intestine mucous membrane with low salt

A crude heparin, pig small intestine technology, applied in the field of crude heparin sodium extraction technology, can solve problems such as high-salt wastewater pollution, and achieve the effects of strong operability, reduced salt concentration, and complete separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This example relates to a method for preparing crude heparin sodium using low-salt porcine small intestinal mucosa, including low-salt compound enzymolysis to obtain enzymolysis solution, enzymolysis solution concentration to obtain concentrated solution, ion exchange to obtain crude heparin sodium eluate and alcohol lake There are four steps in drying to obtain heparin sodium.

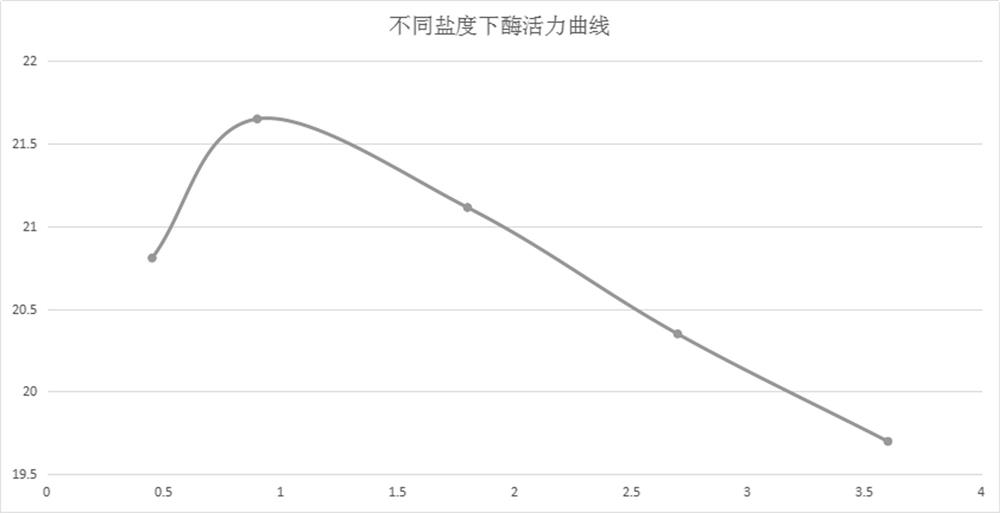

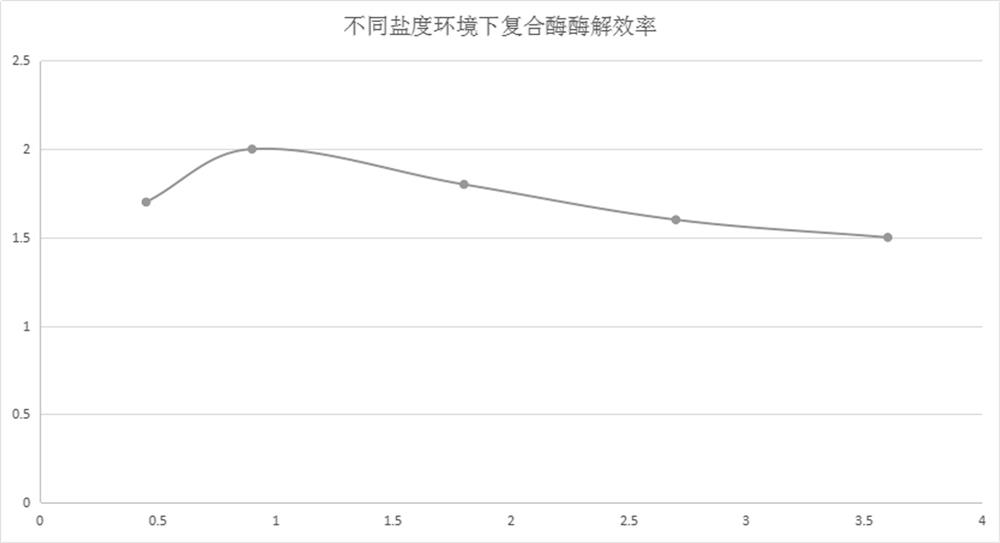

[0043] Step 1, low-salt compound enzymatic hydrolysis: prepare the mucous membrane solution of the pig small intestine, add saturated saline solution, adjust the salt concentration of the mucous membrane solution to 0.8-1.0% by mass, adjust the pH of the mucous membrane solution to 7.0-8.0; raise the temperature to 50-55°C, add complex enzymes for enzymolysis to obtain an enzymolysis solution. Specifically, first put the fresh porcine small intestine mucosal solution into the enzymatic hydrolysis reaction tank, preferably, the mass ratio of mucous membrane to water in the porcine small intestin...

Embodiment 2

[0062] This example relates to a method for preparing crude heparin sodium using low-salt porcine small intestinal mucosa, which is a specific application under Example 1.

Embodiment 21

[0064] 1.1 Put the mucous fluid scraped from pig small intestines into the enzymatic reaction tank, the number of small intestines is 1450, and the volume is 10700L.

[0065] 1.2 Turn on the stirring, add 400L of saturated casing saline to the enzymolysis reaction tank, set the volume to 12050L, and adjust the salt concentration of the mucous membrane to 0.91%.

[0066] 1.3 Add 37L of 25% NaOH solution to the enzymolysis reaction tank, and use PH5.5-9.0 precision test paper to measure the pH to 7.5.

[0067] 1.4 Turn on the steam and raise the temperature to 52°C. Add 2.7kg of complex protease and keep warm for 2h. Raise the temperature to 83°C and keep it warm for 25 minutes. Cool down to 55°C with cooling water.

[0068] 1.5 Add 40kg of anion resin to the enzymolysis reaction tank, stir to absorb heparin for 8 hours, and collect the resin with an 80-mesh filter bag.

[0069] 1.6 Wash the resin with 72L of 2% NaCl solution by mass fraction to remove impurities such as pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com