Preparation method of yellow brown soil derived porous carbon material

A technology of porous carbon material and yellow-brown soil, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of complex hard template synthesis process, long investment return period, limited production scale, etc., and save preparation costs. , saving preparation time, convenient collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

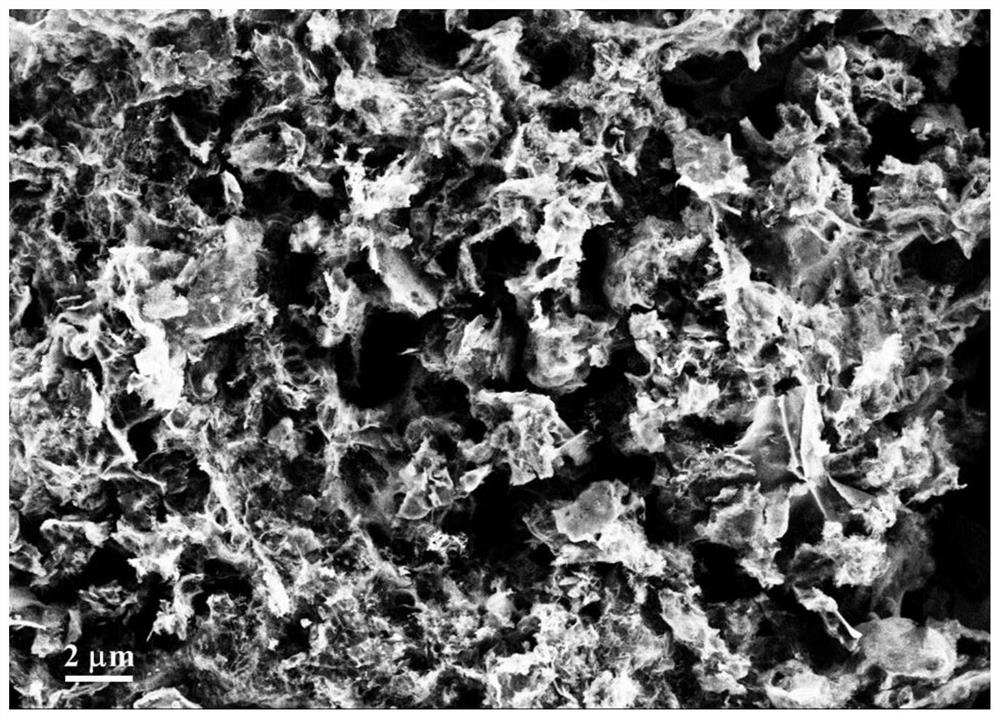

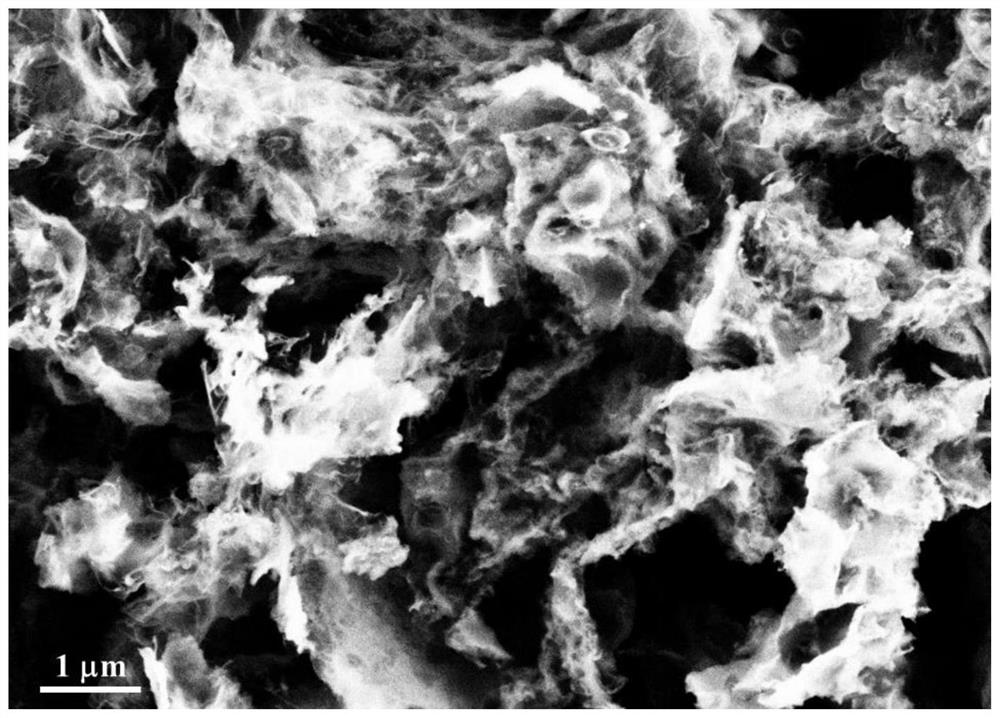

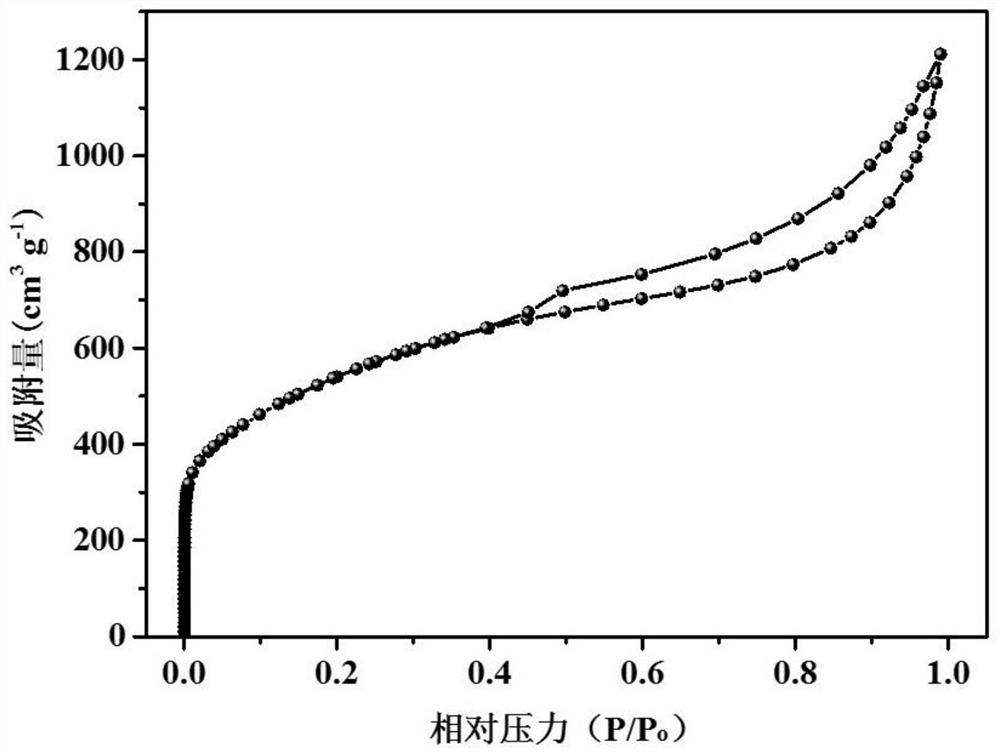

[0037] (1) Collect the yellow-brown soil with a surface depth of 10cm in Yangzhou area, remove impurities and dry it at 105°C, grind the blocky sample into powder and pass through a 400-mesh standard sampling sieve to obtain a brown yellow-brown soil fine powder;

[0038] (2) Weigh yellow-brown soil fine powder and white potassium carbonate particles with a mass ratio of 0.5:1, put them into an agate ball mill jar and carry out mechanical ball milling to obtain brown fine powder, wherein the ball milling speed is 400r / min, and the ball milling time is 5h , the brown fine powder is passed through a 500-mesh standard sampling sieve, and stored for subsequent use; 15g of the brown fine powder is placed in a reaction vessel as a hard template material, and 30g of a mass concentration is added to be an ethanol solution of 10wt% resole phenolic resin, and the reaction vessel is opened The brown solid product was obtained by low-temperature heat treatment in the air. The low-temperatu...

Embodiment 2

[0042] (1) Collect the yellow-brown soil with a surface depth of 10cm in Yangzhou area, remove impurities and dry it at 105°C, grind the blocky sample into powder and pass through a 400-mesh standard sampling sieve to obtain a brown yellow-brown soil fine powder;

[0043] (2) Take by weighing the yellow-brown earth fine powder and white potassium carbonate particle that mass ratio is 1:1, put into the agate ball mill jar and carry out mechanical ball milling and obtain brown fine powder, wherein the rotating speed of ball milling is 400r / min, and the ball milling time is 5h, pass the brown fine powder through a 500-mesh standard sampling sieve, and save it for later use; take 15g of the brown fine powder as a hard template material and place it in a reaction vessel, add 30g of a mass concentration of 10wt% ethanol solution of resole phenolic resin, and place it in the reaction vessel The brown solid product was obtained by low-temperature heat treatment in the open air. The low...

Embodiment 3

[0047] (1) Collect the yellow-brown soil with a surface depth of 10cm in Nanjing area, remove impurities and dry it at 105°C, grind the bulk sample into powder and pass through a 400-mesh standard sampling sieve to obtain a brown yellow-brown soil fine powder;

[0048] (2) Weigh yellow-brown soil fine powder and white potassium carbonate particles with a mass ratio of 2:1, put them into an agate ball mill jar for mechanical ball milling to obtain brown fine powder, wherein the ball milling speed is 400r / min, and the ball milling time is 5h , pass through a 500-mesh standard sampling sieve, and save for subsequent use; take 15g of brown fine powder as a hard template material and place it in a reaction vessel, add 30g of a mass concentration of 10wt% ethanol solution of resole phenolic resin, and the reaction vessel is exposed to the air A brown solid product was obtained by low-temperature heat treatment, wherein the low-temperature heat treatment process was: successively kept...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com