High-speed and high-load hub bearing unit and assembling method thereof

A wheel bearing, high load-bearing technology, applied to bearing components, shafts and bearings, assembly machines, etc., can solve the problems of reducing bearing service life, bearing heating, bearing deformation, etc., to increase stability and carrying capacity, and increase service life , to avoid the effect of deformation and cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

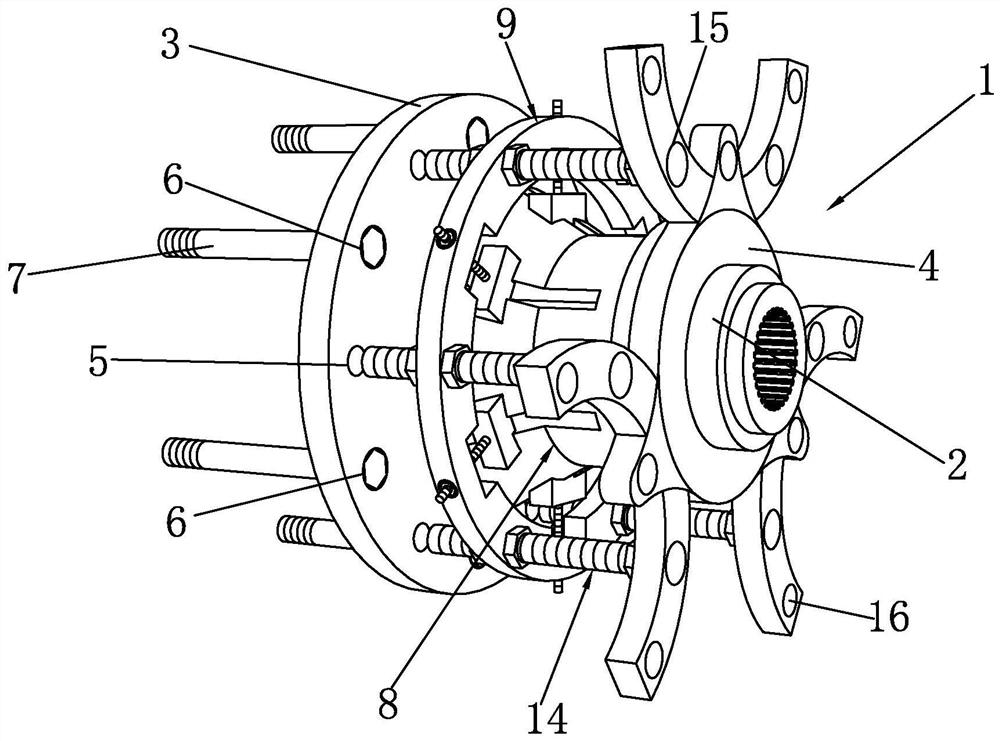

[0045] like Figure 1 to Figure 4 As shown, it is a high-speed and high-load hub bearing unit of the present invention, which includes a body 1, a bearing sleeve 2 is provided on the body 1, an inner flange 3 arranged at the front end of the bearing sleeve 2 is fixedly connected to the rear of the bearing sleeve 2 The fixed disc 4 on the outer wall of the end and the inner flange 3 are distributed with positioning holes 5 and mounting holes 6 around the circumference, the positioning holes 5 and the mounting holes 6 are arranged at intervals, and the mounting holes 6 are provided with connecting screws 7 .

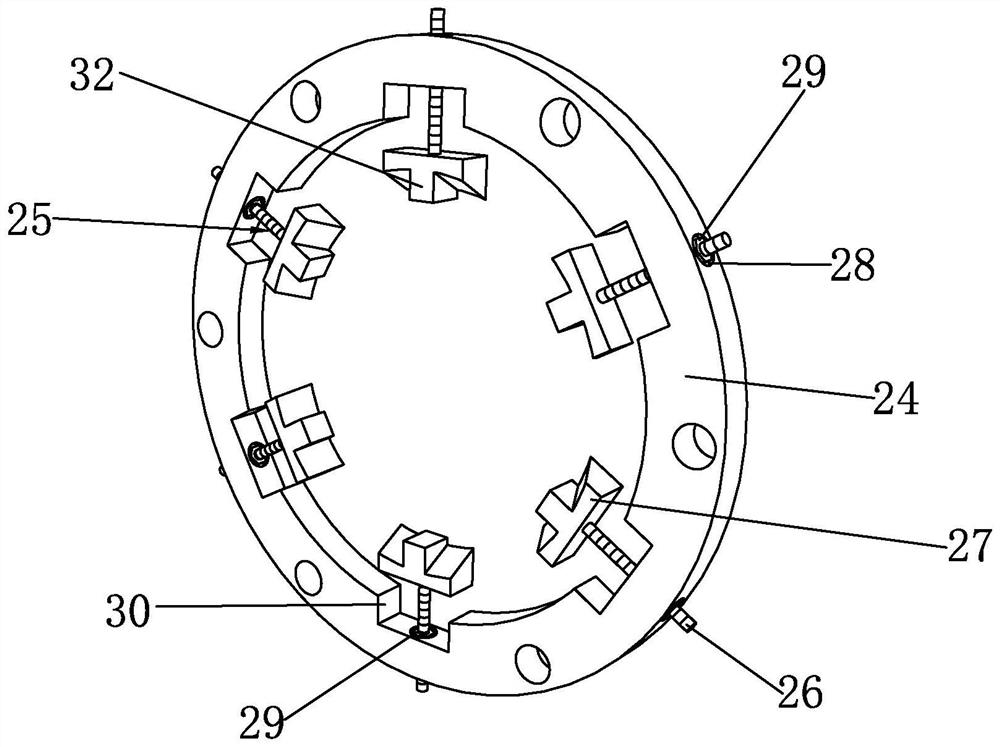

[0046] The outer sleeve of the bearing sleeve 2 is provided with a reinforcement sleeve 8, the reinforcement sleeve 8 is located between the inner flange 3 and the fixed plate 4, the fixed plate 4 is provided with a clamping assembly 9, and the clamping assembly 9 clamps the reinforcement sleeve 8, so that the reinforcement Cover 8 clamps the outer side wall of bearing sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com