A method for monitoring switching force of a switch machine

A switch machine and force sensor technology, applied in force/torque/power measuring instruments, measuring force, measuring devices, etc., can solve the problems of poor timeliness and cumbersome process of measurement methods, and achieve good timeliness, accurate acquisition, and data Accurate and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

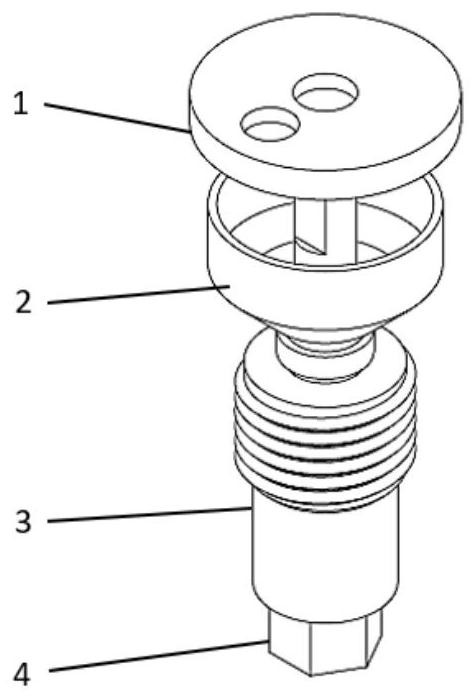

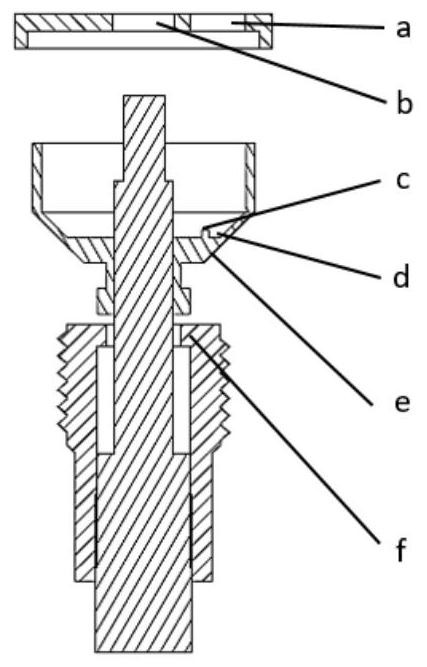

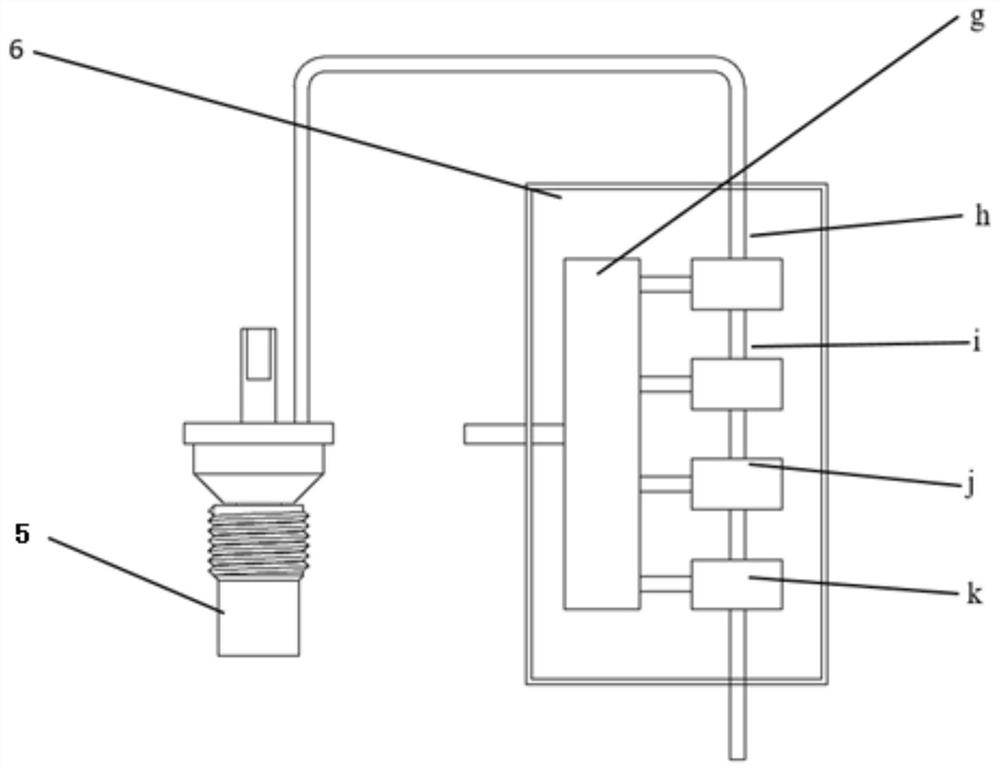

[0025] The measuring device used among the present invention comprises conversion force sensor 5 and conversion force collector 6, and concrete composition and connection relation are as Fig. 1 (a) and Fig. 1 (b) and figure 2 shown.

[0026] In this embodiment, the material of the switch machine action rod is steel, and the conversion force sensor 5 is installed in the through hole located at the neutral axis. The shape and size of the tapered hole match the conversion force sensor 5, and its upper part is a straight hole. The diameter is 17mm, the depth is 20mm, and the middle section is a conical structure, which is matched with the outer conical surface e of the conical cylinder structure at the lower part of the conical force-sensitive structure 2. The lower half is a straight hole and the surface is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com