Eddy current type particle inerter damper

A particle damping and eddy current technology, applied in protective buildings/shelters, building components, shockproof, etc., can solve the problems of less number of particle collisions, unstable damping properties, limited energy consumption, etc., to improve vibration reduction effect, increase the robustness of vibration reduction, and the effect of high collision efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

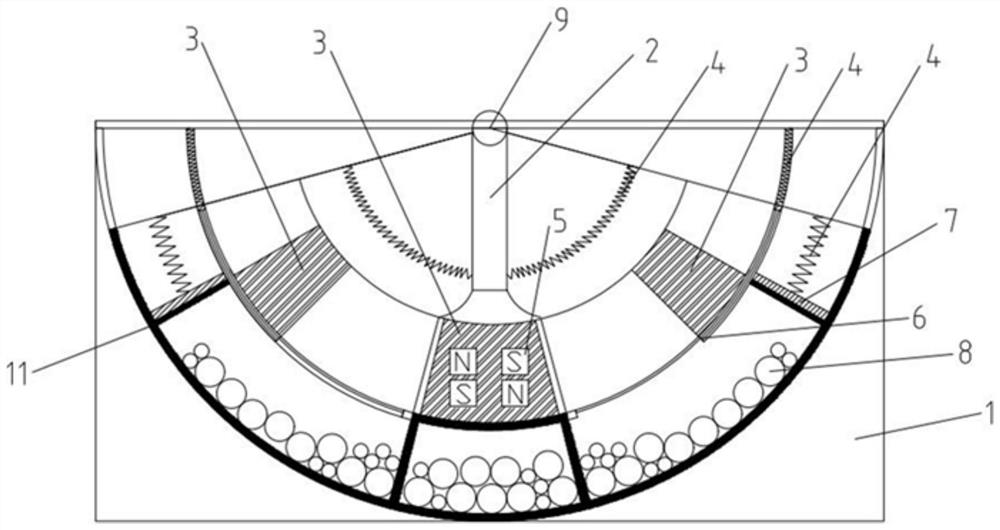

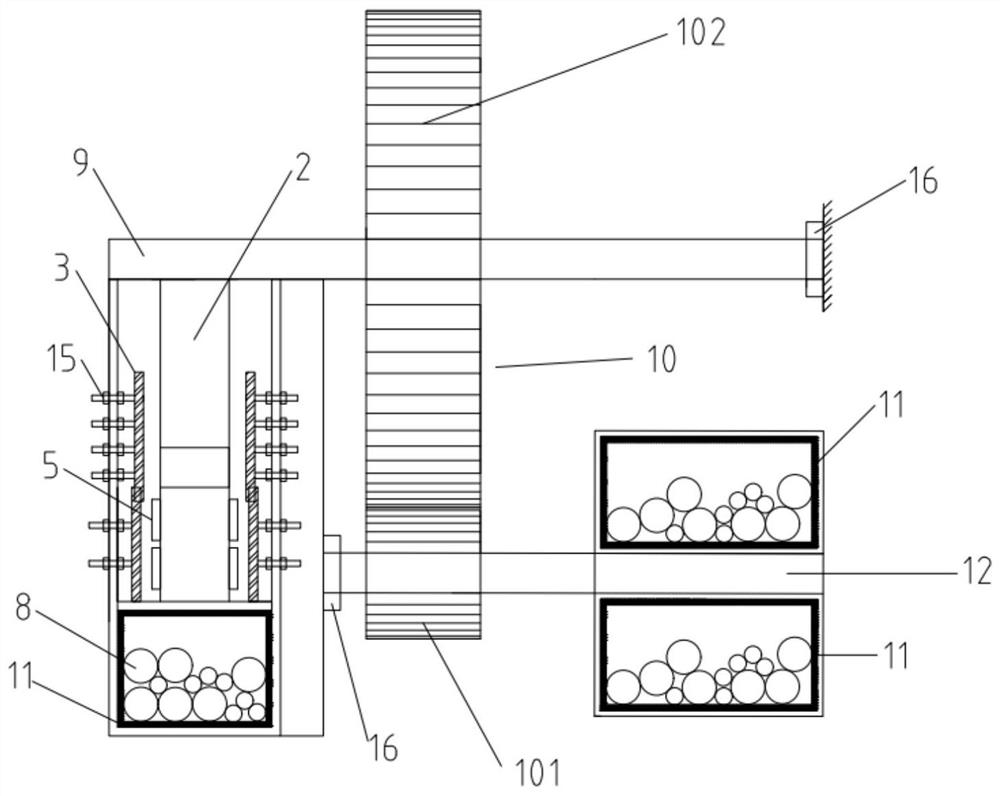

[0039] Such as figure 1 , 2 As shown, it is an eddy current type particle inertial damper, which includes a single pendulum damping unit and a particle inertial unit. Connected, the rotating shaft 12 drives the rotary drum 14 in the particle inertial unit to rotate.

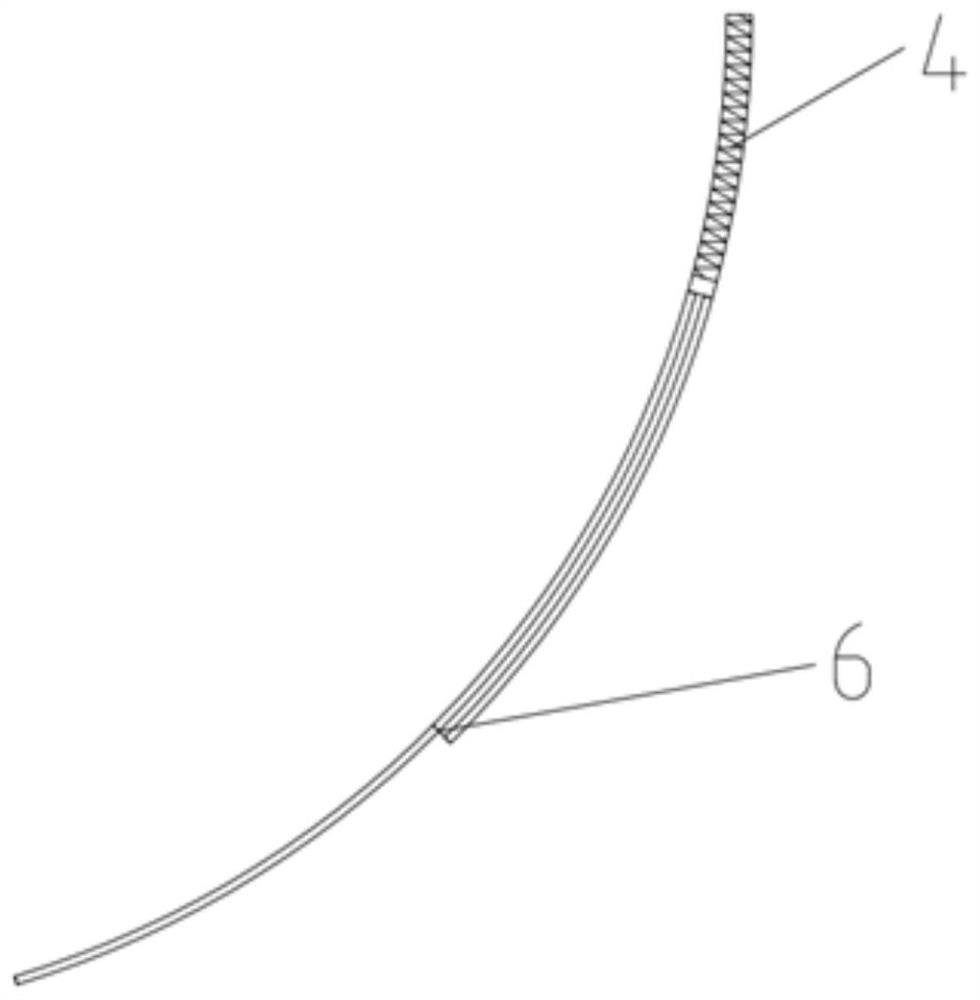

[0040] In this embodiment, the pendulum damping unit includes a pendulum damping unit box 1, a pendulum mass body 2, a conductor plate 3, a spring 4, a permanent magnet 5, an elastic expansion plate 6, a buffer baffle 7, particles 8, and a transmission shaft 9. Cushioning material 11, bolts 15; the upper end of the pendulum mass body 2 is fixed on the drive shaft 9, when the structure vibrates, the pendulum mass body 2 and the conductor plate 3 move relative to each other to generate eddy current damping, driving the drive shaft 9 Rotate, and increase the impact efficiency of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com