Anti-rust lubricating bolt loosening agent and preparation method thereof

A bolt loosening agent, anti-rust lubrication technology, applied in lubricating compositions, petroleum industry and other directions, can solve the problems of poor effect, high difficulty in disassembly and processing, and achieve the effect of simple preparation and clean bolt loosening ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

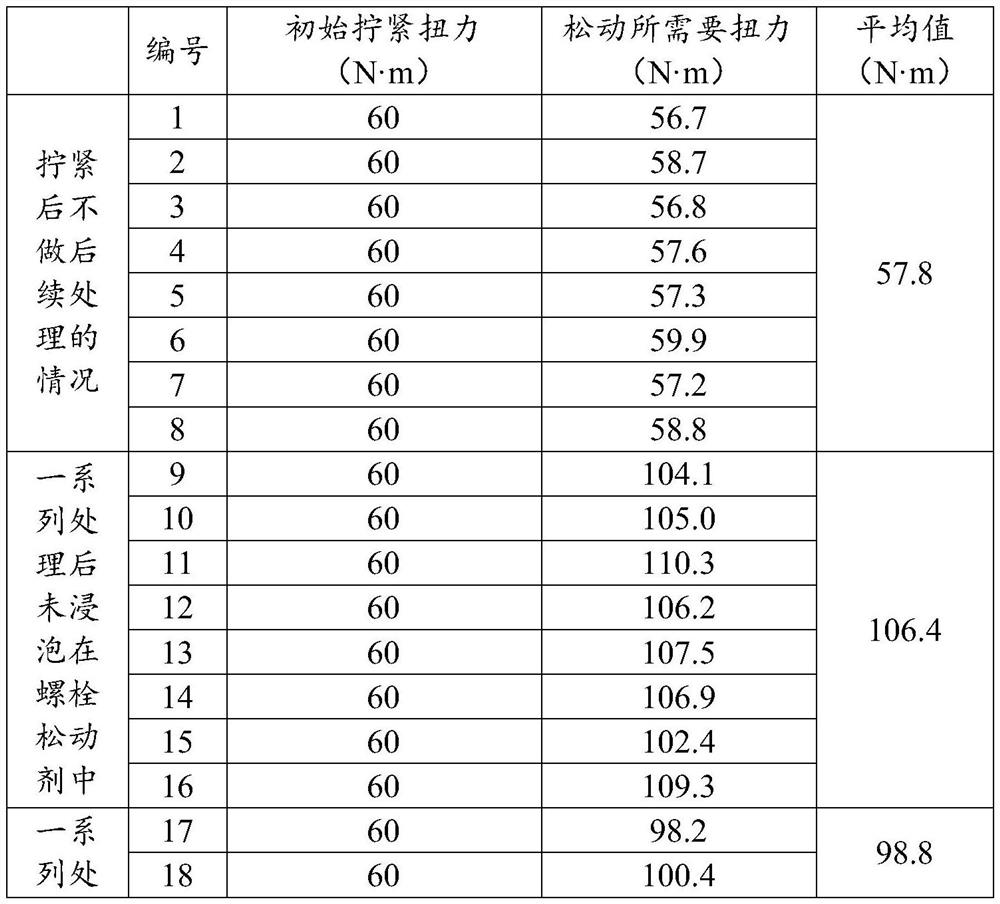

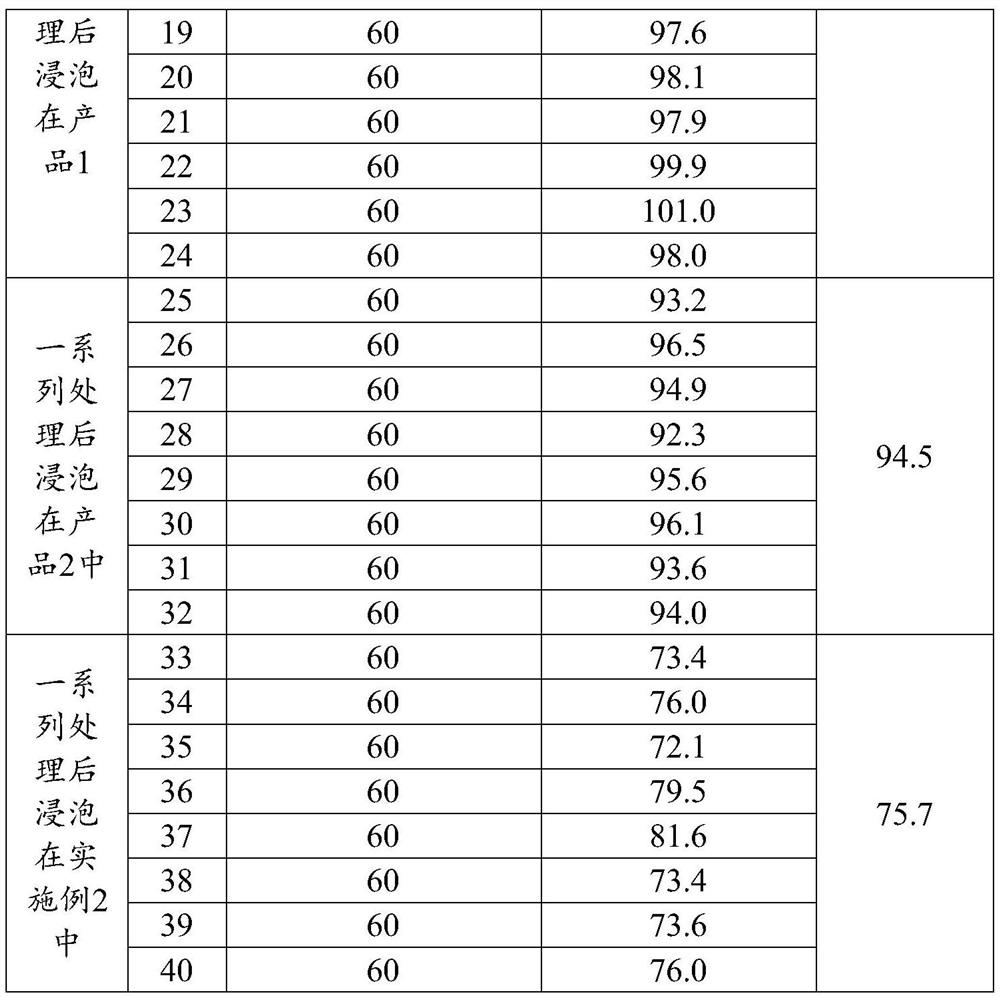

Examples

Embodiment 1

[0023] An anti-rust lubricating bolt loosening agent comprises the following components in mass percentage: 70%-90% of solvent oil, 4%-15% of anti-rust additive, 4%-15% of lubricating additive and 0.5%-3% of antioxidant.

[0024] The isoparaffin solvent oil is one or more of the isoparaffin solvent oil ISOPAR M, ISOPAR L, ISOPAR H, and EXXSOL D40 of the manufacturer ExxonMobil.

[0025] Anti-rust additives are zinc naphthenate, benzotriazole, fatty ammonium salt of benzotriazole, petroleum resin, tert-butyl phenolic resin, Span 80, N-oleoyl acid octadecyl ammonium salt, alkenyl One or more of succinates.

[0026] The lubricating additive is one or more of chlorinated paraffin, di-n-butyl phosphite, thionyl butadioctyl octyl salt, nitrogen-containing derivatives of sulfuric acid, butyl stearate, pentaerythritol oleate, and isooctyl stearate kind.

[0027] The antioxidant is 2,6-di-tert-butyl-p-cresol.

[0028] A method for preparing a rust-proof lubricating bolt loosening ag...

Embodiment 2

[0033] A kind of anti-rust lubricating bolt loosening agent, comprising the following components by mass percentage: EXXSOL D40 40%, ISOPAR M 40%, tert-butyl phenolic resin (2402) 1%, N-oleoyl amino acid octadecyl ammonium salt 3% , benzotriazole 2%, Span 80 4%, pentaerythritol oleate 3%, isooctyl stearate 3%, di-n-butyl phosphite 2% and 2,6-di-tert-butyl p-methyl Phenol 2%.

[0034] First set the incubator to 80°C, and keep N-oleoyl acid octadecyl ammonium salt at this temperature for 24 hours until it reaches a liquid state;

[0035] (1) Then add EXXSOL D40 and ISOPAR M to the reaction pot in turn to raise the temperature of the reaction pot to 60°C;

[0036] (2) Add Span 80, pentaerythritol oleate, isooctyl stearate, di-n-butyl phosphite, 2,6-di-tert-butyl p-cresol, benzotriazole, N-oleoylamine Octadecyl ammonium salt, stirred for 2h until the solution was clear and transparent;

[0037] (4) Cool to room temperature, and then discharge and fill.

Embodiment 3

[0039] A kind of anti-rust lubricating bolt loosening agent, comprising the following components by mass percentage: EXXSOL D40 60%, ISOPAR M 15%, tert-butyl phenolic resin (2402) 1%, N-oleoyl amino acid octadecyl ammonium salt 4% , benzotriazole 1%, Span 80 6%, pentaerythritol oleate 6%, isooctyl stearate 4%, di-n-butyl phosphite 1% and 2,6-di-tert-butyl p-methyl Phenol 2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com