Cool bamboo charcoal memory foam throw pillow

A technology of memory foam and cool bamboo, which is applied in pillows and other directions, can solve the problems of aggravated stuffy feeling, slow rebound memory, and easy stuffy feeling, so as to achieve the effect of absorbing odor and improving the killing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

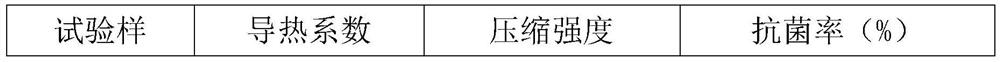

Examples

Embodiment 1

[0036] Embodiment 1: A kind of cool and refreshing bamboo charcoal memory foam pillow, comprising a pillowcase, a polyurethane memory foam pillow core filled in the pillowcase, the fabric of the pillowcase is bamboo charcoal viscose fiber and polyester fiber blended fabric, the bamboo charcoal viscose of the pillowcase fabric The fiber mass percentage is 30%, and the balance is polyester fiber.

[0037] The inner side of the pillowcase is stitched with a cooling gel sheet, which is prepared from the following raw materials by weight: 55 parts of combined polyether polyol, 15 parts of high-resilience polyether polyol, and 10 parts of warm-sensing polyether , 8 parts of hydrophobic polyol polyether, 5 parts of antibacterial and antifungal agent, 0.3 part of chain extender, 0.1 part of chain extension crosslinking agent, 0.9 part of weak catalyst, 0.5 part of foaming agent, 0.3 part of foam stabilizer, natural bamboo charcoal powder 15 parts, 8 parts of cooling additive, 45 parts...

Embodiment 2

[0039] Embodiment 2: a kind of cool and refreshing bamboo charcoal memory foam pillow, the difference from embodiment 1 is that the bamboo charcoal viscose fiber mass percentage content of the pillow cover fabric is 35%, and the balance is polyester fiber. The cooling gel sheet in the pillow case is prepared from the following raw materials in parts by weight: 60 parts of combined polyether polyol, 18 parts of high resilience polyether polyol, 10.5 parts of warm-sensitive polyether, and 9 parts of hydrophobic polyol polyether , 5.5 parts of antibacterial and antifungal agents, 0.4 parts of chain extenders, 0.2 parts of chain extension crosslinking agents, 0.95 parts of weak catalysts, 0.7 parts of foaming agents, 0.4 parts of foam stabilizers, 17 parts of natural bamboo charcoal powder, and 9.5 parts of cooling additives , 47 parts of isocyanate;

[0040] Wherein, the combined polyether polyol includes two mixtures of polymer polyol A with a hydroxyl value of 22 mgKOH / g and po...

Embodiment 3

[0041] Embodiment 3: a kind of cool and refreshing bamboo charcoal memory foam pillow, the difference with embodiment 1 is that the bamboo charcoal viscose fiber mass percentage content of the pillow cover fabric is 40%, and the balance is polyester fiber. The cooling gel sheet in the pillowcase is prepared from the following raw materials in parts by weight: 65 parts of combined polyether polyol, 22 parts of high resilience polyether polyol, 11 parts of warm-sensitive polyether, and 10 parts of hydrophobic polyol polyether , 6 parts of antibacterial and antifungal agents, 0.5 parts of chain extenders, 0.3 parts of chain extension crosslinking agents, 1.0 parts of weak catalysts, 0.9 parts of foaming agents, 0.5 parts of foam stabilizers, 19 parts of natural bamboo charcoal powder, 11 parts of cooling additives , 50 parts of isocyanate;

[0042] Wherein, the combined polyether polyol includes two mixtures of polymer polyol A with a hydroxyl value of 23 mgKOH / g and polymer poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com