Environment-friendly construction waste ship loader capable of conveniently removing returned materials

A construction waste and ship loader technology, which is applied in cleaning devices, transportation and packaging, loading/unloading, etc., can solve the problems of difficult cleaning, pollution of the surrounding environment, affecting the normal use of chain conveyors, etc., to ensure normal use, The effect of protecting the surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

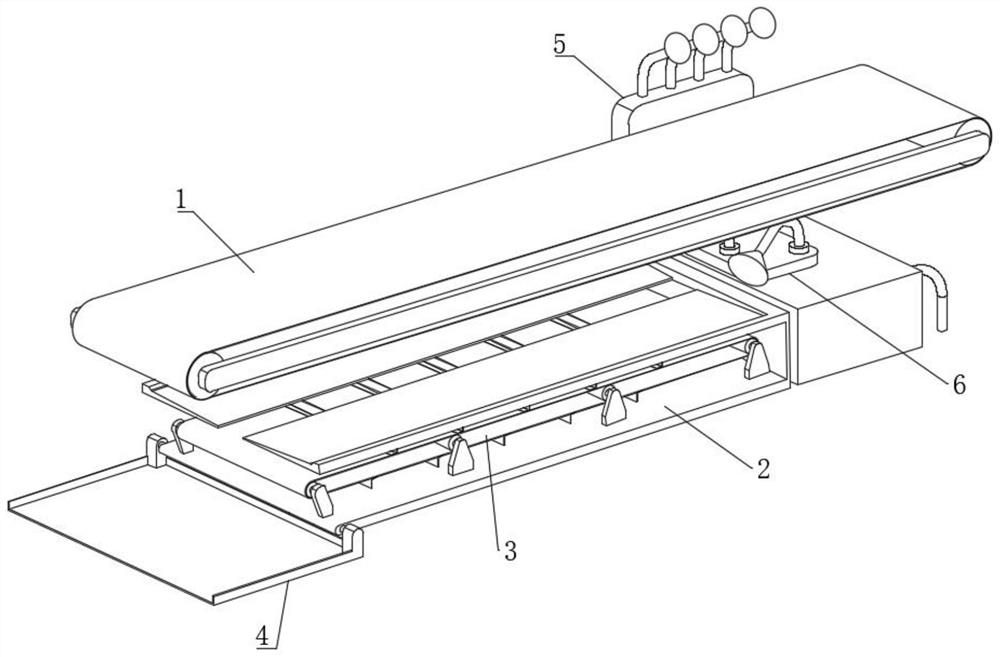

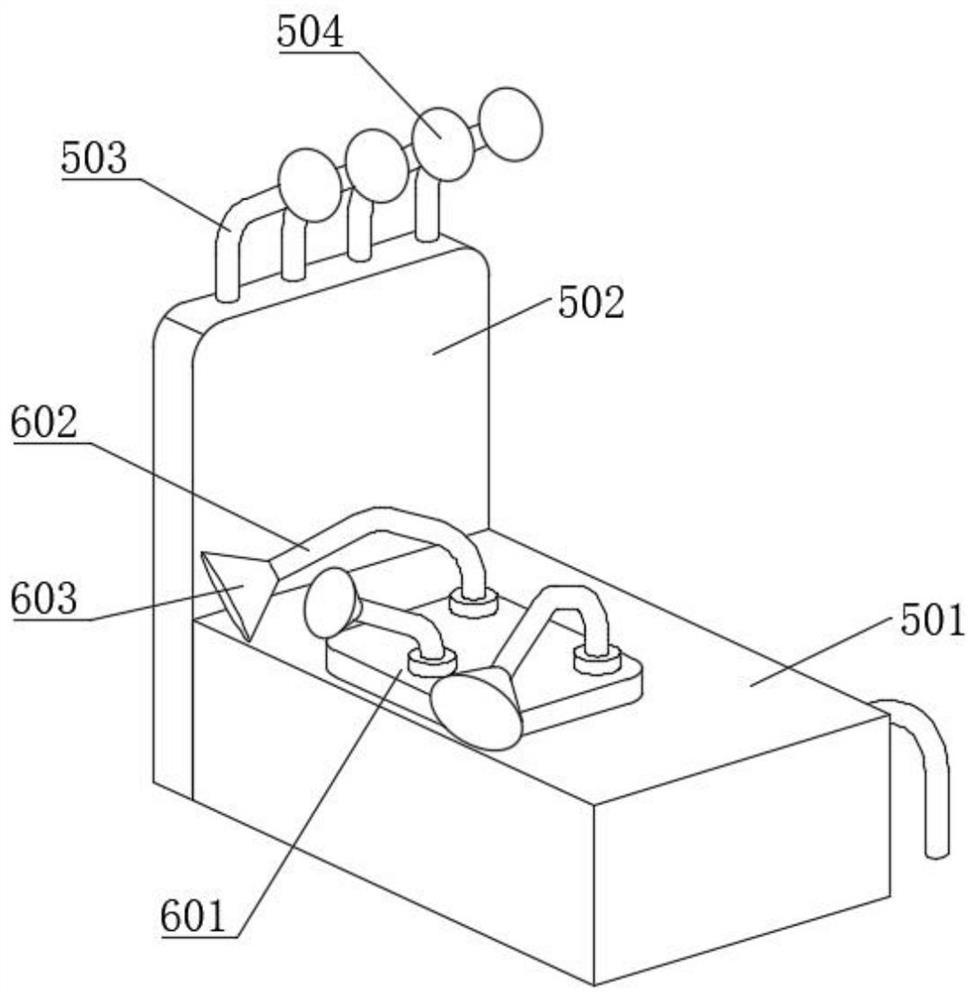

[0048] see Figure 1-9 , an environmental protection ship loader for construction waste that is easy to remove back materials, including a chain plate conveyor belt 1, a dust receiving frame 2 is provided on the lower side of the chain plate conveying belt 1, and a chain conveyor is fixedly installed in the dust receiving frame 2 Belt 3, the left end of the dust receiving frame 2 is provided with a material guide assembly 4, the right end of the dust receiving frame 2 is provided with a dust removal assembly 5 matching the chain conveyor belt 1, and the upper end of the dust removal assembly 5 is provided with a blower assembly 6 ; see figure 2 , the dust removal assembly 5 includes a water tank 501, the left end of the dust receiving frame 2 is fixedly connected with a water tank 501, and the rear end of the water tank 501 is fixedly connected with a water collecting plate 502 communicating with it; the blower assembly 6 includes a blower 601, a blower 601 is fixedly instal...

Embodiment 2

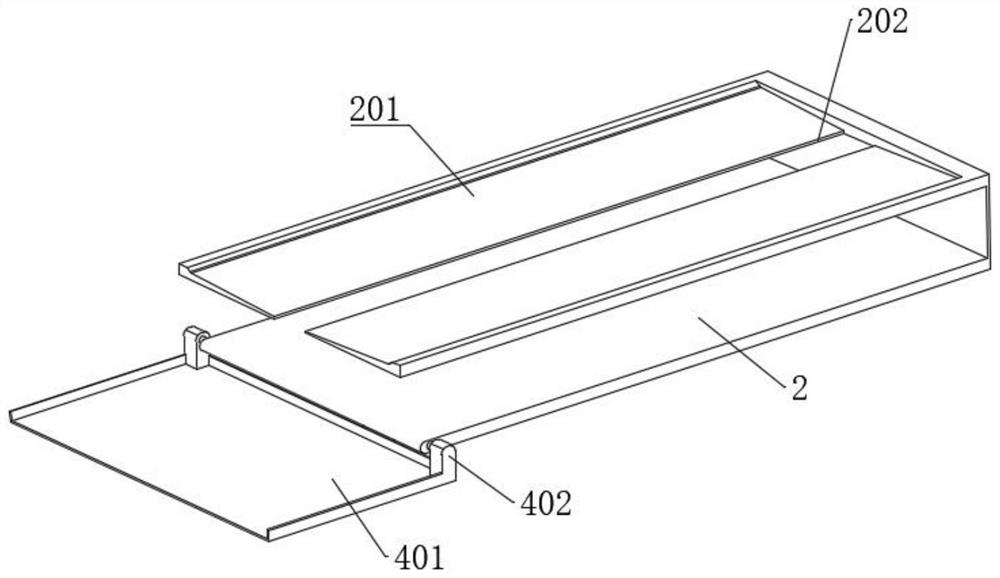

[0057] see figure 1 and image 3 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 2 and embodiment 1 is: please refer to image 3 , The lower inner wall of the dust receiving groove 201 is an inclined surface, and the inclination angle is 2°-6°. The lower inner wall of the dust receiving trough 201 is an inclined surface, which guides the dust and impurities so as to facilitate its falling onto the chain conveyor belt 3, effectively preventing smaller dust and impurities from accumulating in the dust receiving trough 201 to stop blanking.

Embodiment 3

[0059] see figure 1 and image 3 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 3 and embodiment 1 is: please refer to image 3 , the total length of the dust-receiving frame 2 is 0.6-0.8 times the length of the working surface of the chain conveyor belt 1, and the total width of the dust-catching frame 2 is 1-1.4 times the width of the working surface of the chain conveyor belt 1. The dust receiving frame 2 can be effectively used in conjunction with the chain conveyor belt 1, effectively accepting the dust and impurities adhered to the chain conveyor belt 1, and in the event of strong wind or rainy weather, the dust receiving frame 2 can effectively accept the dust from the chain conveyor belt 1. The falling dust, impurities and muddy water are washed away o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com