Watch lens grinding equipment

A lens and equipment technology, applied in the field of watch lens grinding equipment, to achieve the effect of smooth surface, uniform grinding, and avoiding limited range of motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

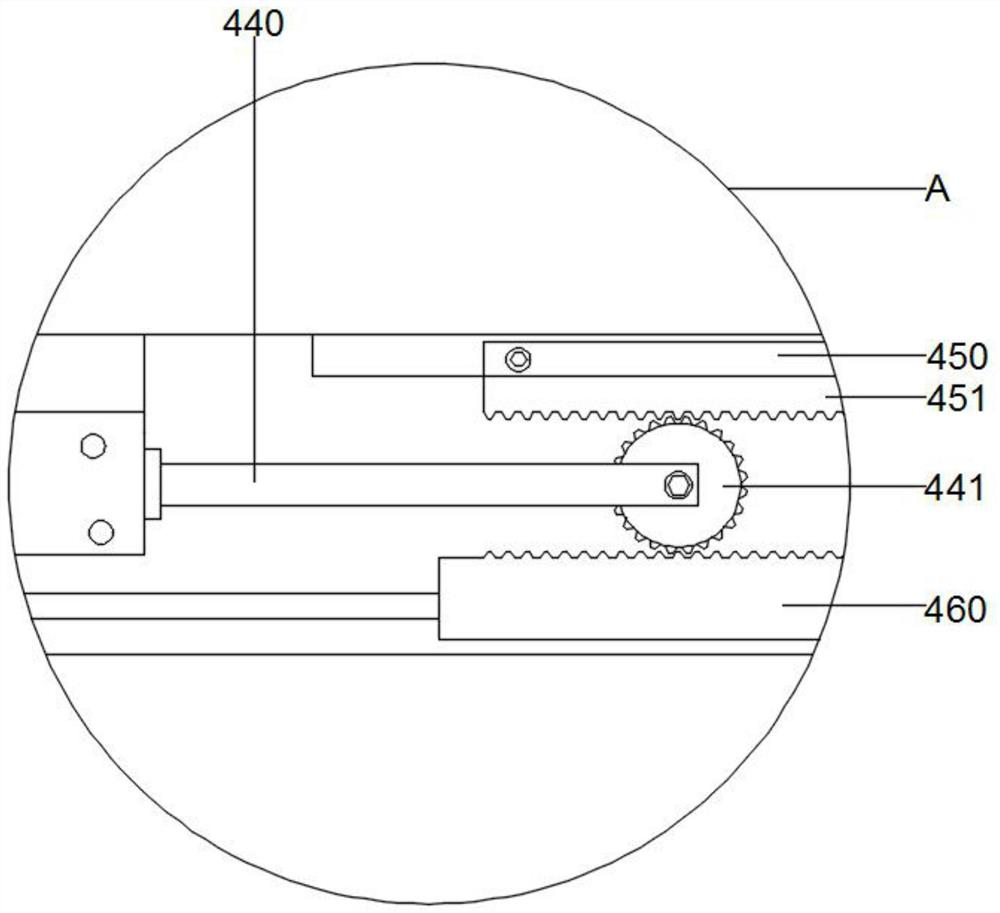

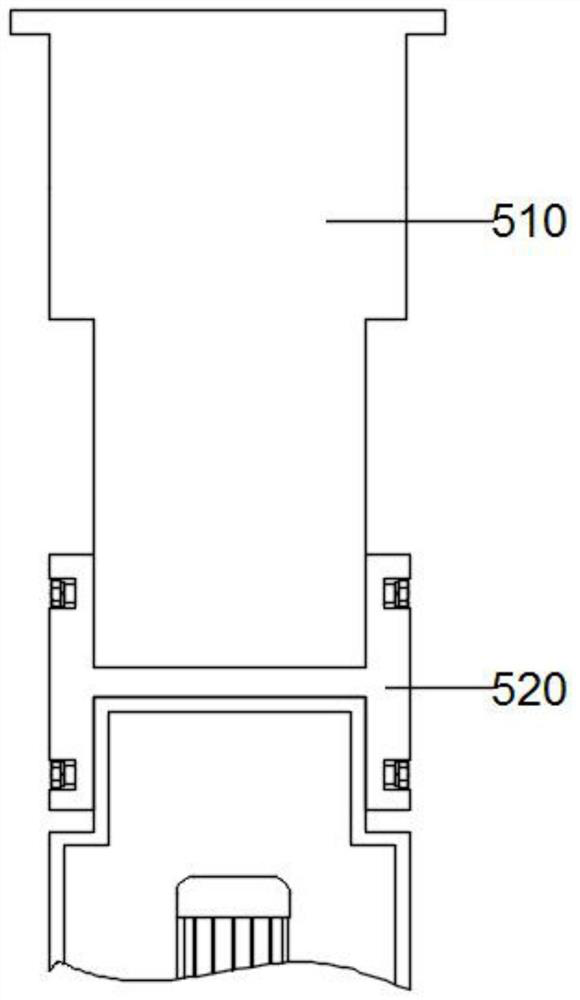

[0026] Refer to attached Figure 1-5 , a kind of watch lens polishing equipment provided by the present invention, comprises base 100, workbench 200, clamping device 300, moving device 400, lifting device 500, horizontal rotation device 600, angle adjustment device 700, vertical rotation device 800 and grinding device 900, specifically, the base 100 includes a horizontal plate 110, the top of the horizontal plate 110 is fixedly installed with a vertical pole 120, the top of the base 100 is provided with a workbench 200, the top of the workbench 200 is fixed with a clamping device 300, and the top of the vertical pole 120 is fixedly installed with a moving device 400, the bottom of the moving device 400 is fixedly connected to the lifting device 500, the top of the lifting device 500 is fixedly connected to the horizontal rotation device 600, the bottom of the horizontal rotation device 600 is flexibly connected to the angle adjustment device 700, the bottom of the angle adjustm...

Embodiment 2

[0037] Refer to attached Figure 6 , a kind of watch lens polishing equipment provided by the present invention, comprises base 100, workbench 200, clamping device 300, moving device 400, lifting device 500, horizontal rotation device 600, angle adjustment device 700, vertical rotation device 800 and grinding device 900;

[0038] Further, the clamping device 300 also includes a servo motor 2 350, the servo motor 2 350 is fixedly installed on the inner and outer wall of the vertical rod 120, two sets of servo motor 350 are symmetrically arranged, and the output end of the servo motor 2 350 is fixedly connected to the rotating block 351, The inner wall of the rotating block 351 is plugged with the cylinder three 360, the output end of the cylinder three 360 is fixedly installed with a protective pad 361, the servo motor two 350 is set as C-PLX310, and the servo motor two 350 has the function of driving the grinding blade 930 to perform rotary grinding, and the rotating block 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com