Bearing end face warping preventing non-magnetic grinding device and method

An anti-warping and end-face technology, applied in the field of bearing processing, can solve the problems of sudden increase in normal grinding force, affecting processing accuracy, elastic deformation of the end face, etc., to eliminate elastic warping, improve grinding accuracy, and delay elastic recovery. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

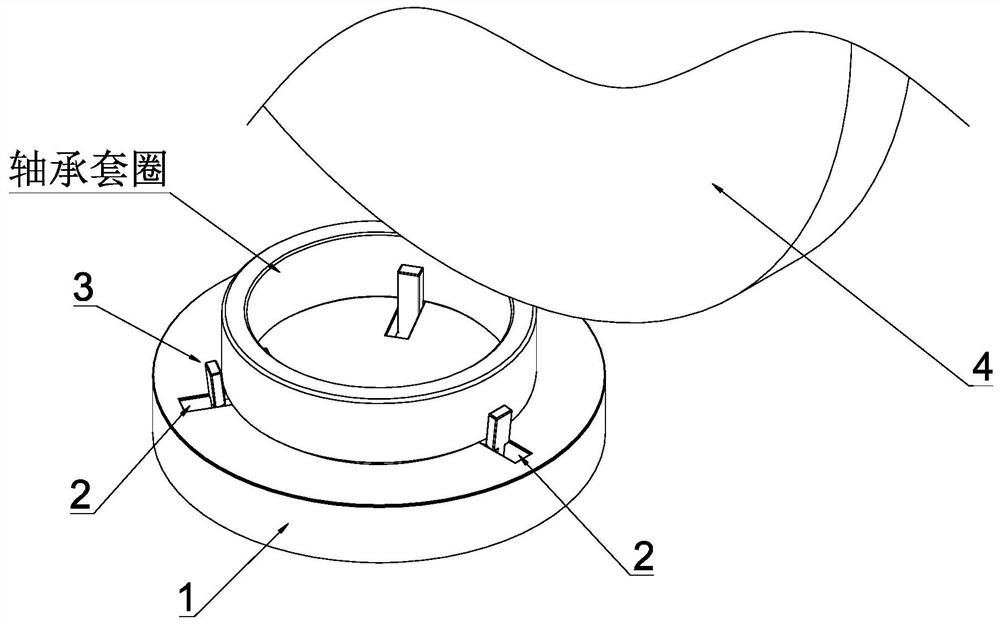

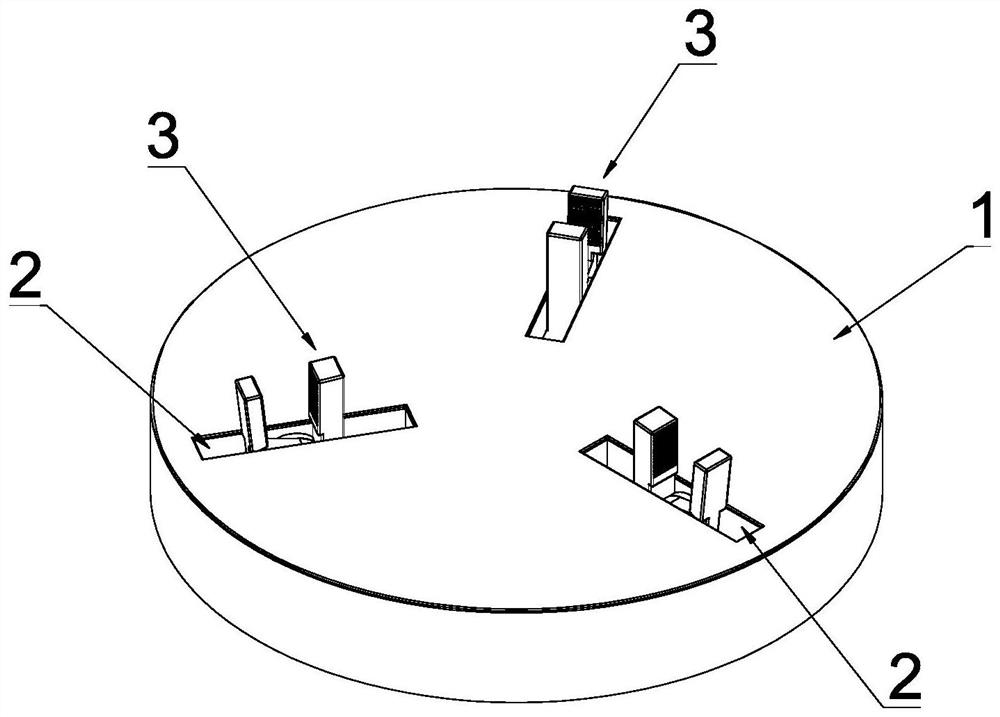

[0043] see Figure 1-Figure 2 , this embodiment discloses a non-magnetic grinding device for preventing warpage of bearing end faces, which includes a workbench 1 arranged on the turntable of the grinder, and the workbench 1 is provided with three slide grooves 2, and the three slide grooves 2 Evenly distributed around the central circumference of the workbench 1, the sliding grooves 2 extend along the radial direction, and each sliding groove 2 is provided with an elastic damping clamping mechanism for clamping the bearing ring and slidingly matching with the sliding groove 2 3. By setting three sliding grooves 2, each sliding groove 2 is evenly distributed in the circumferential direction, and the angle between two adjacent sliding grooves 2 is 120°. Correspondingly, the three elastic damping clamping mechanisms 3 clamp the bearing at the same time When processing the bearing ring, the degree of freedom of the three elastic damping clamping mechanisms 3 on the chute is 0, t...

Embodiment 2

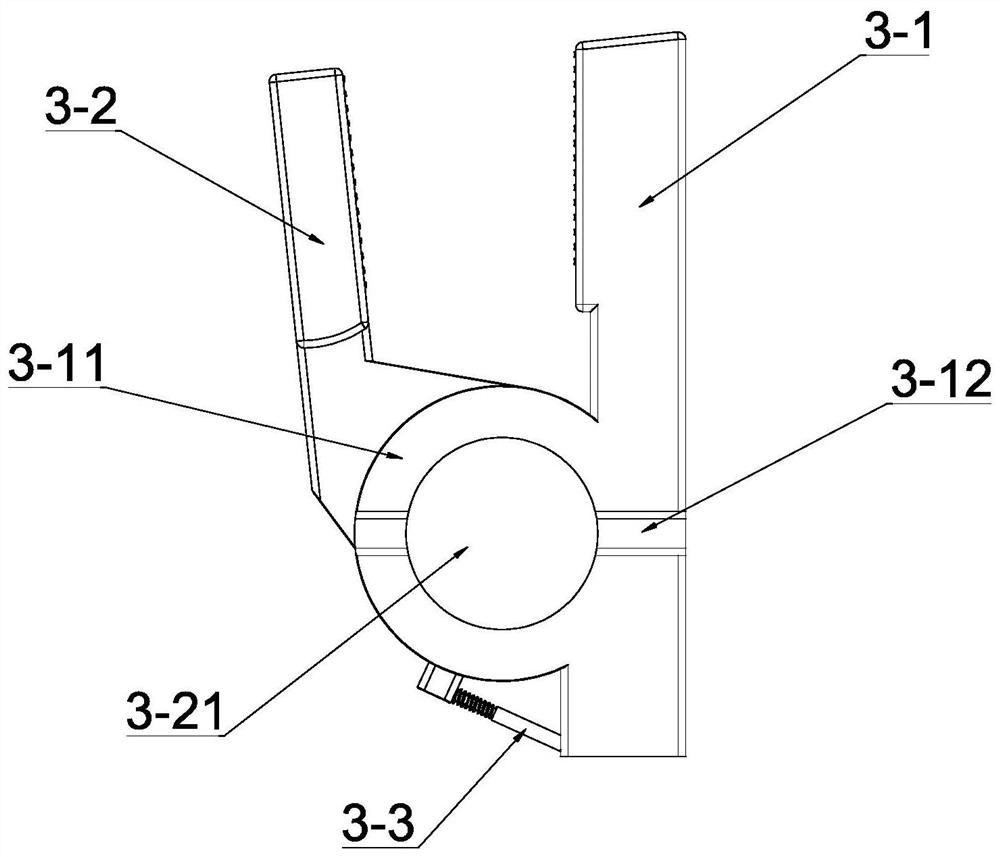

[0063] see Figure 12, the other structures in this embodiment are the same as those in Embodiment 1, the difference is that: the middle part of the first clamp body 3-1 is provided with a hinge seat 3-11, and the middle part of the second clamp body 3-2 The middle part is provided with a hinged shaft 3-21 that is rotatably matched with the hinged seat 3-11, and the elastic damper is a torsion spring 3-8, and the torsion spring 3-8 is sleeved on the hinged shaft 3-21. One end of the torsion spring 3-8 acts on the lower end of the first clamp body 3-1, and the other end acts on the lower end of the second clamp body 3-2. Through the above structure, the clamping function of the first clamp body 3-1 and the second clamp body 3-2 can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com