Rotary press die

一种旋转模具、冲压模具的技术,应用在成型工具、制造工具、运输和包装等方向,能够解决无法进行修正、难以形成直径变化复杂形状等问题,达到高硬度、良好润滑性、确保深度尺寸的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

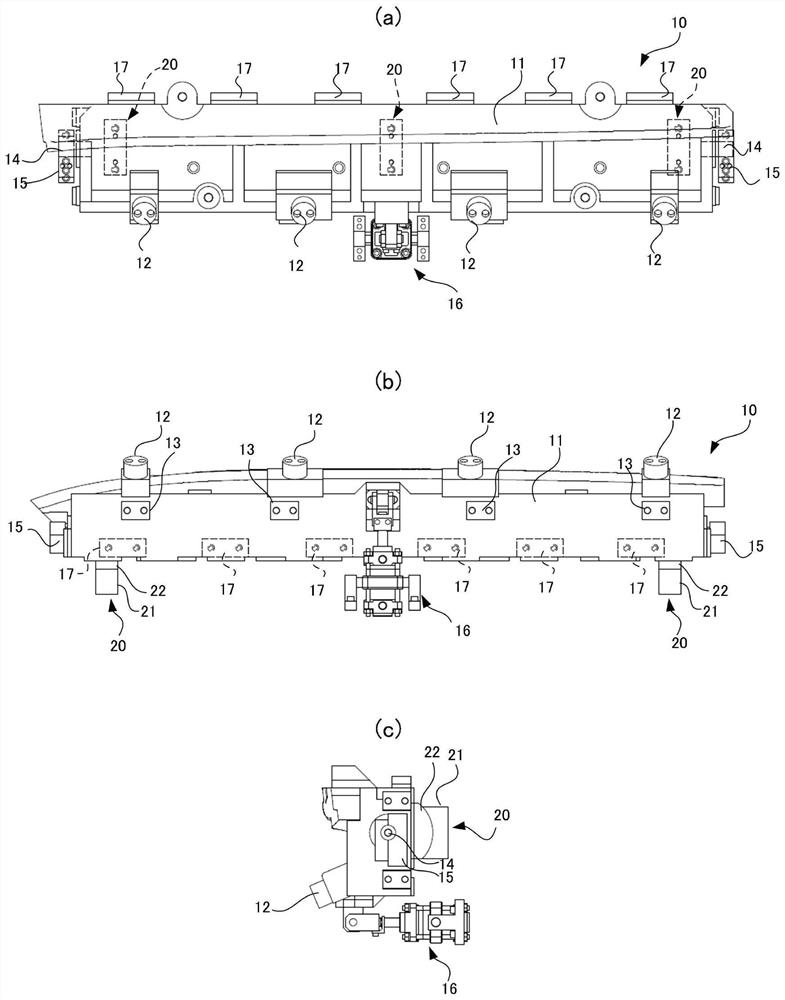

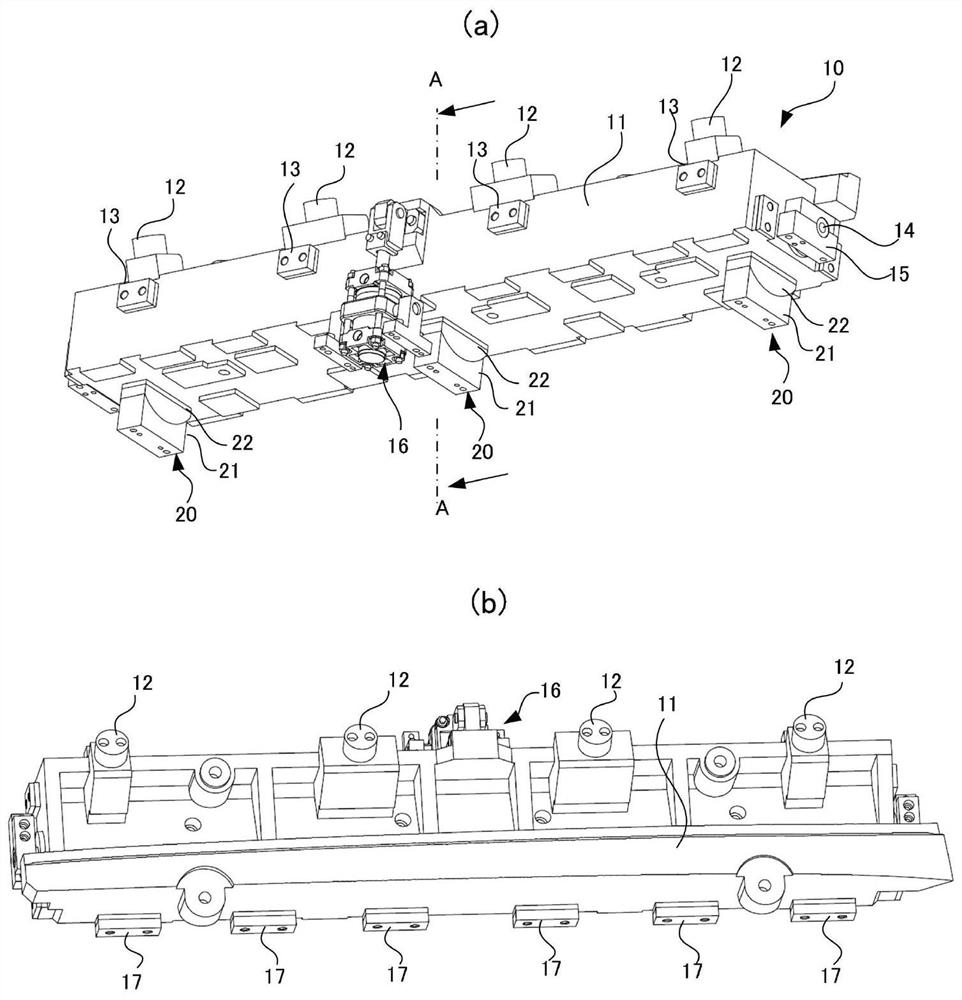

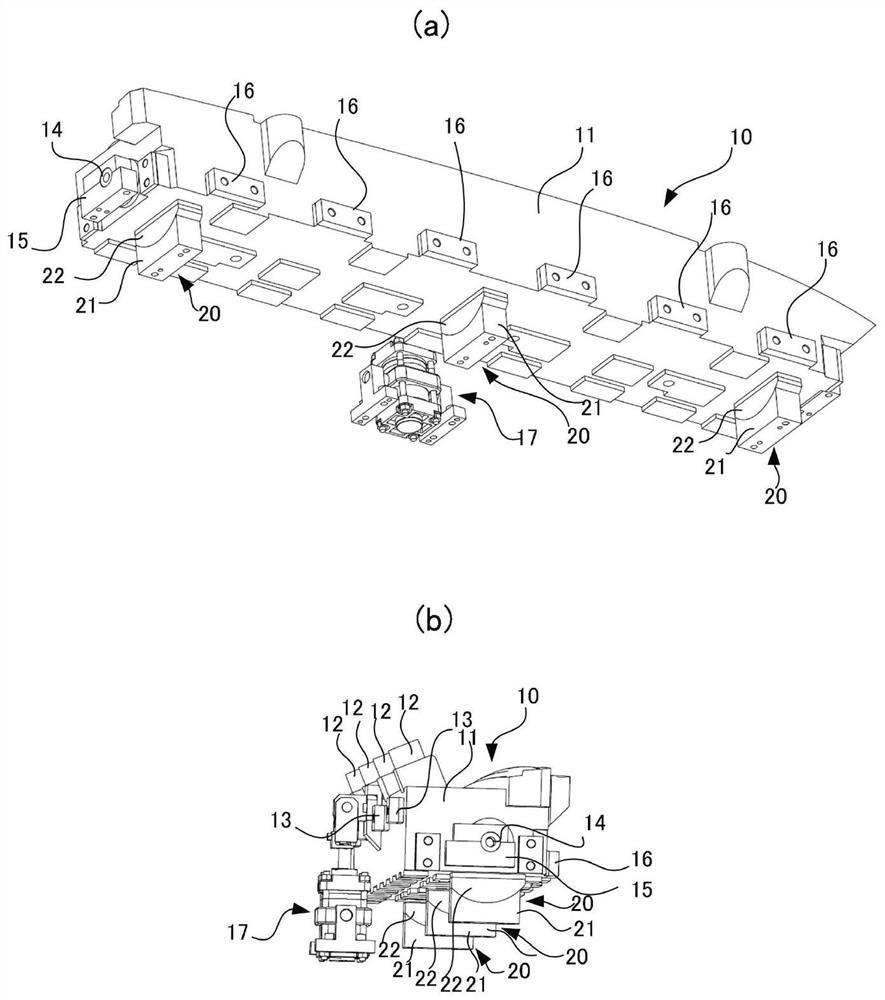

[0042] A first embodiment of the present invention will now be described. figure 1 The rotary die of the rotary press die according to the first embodiment of the present invention is shown, (a) is a plan view of the rotary die, (b) is a front view of the rotary die, and (c) is a side view of the rotary die. figure 2 The rotary die of the rotary punching die according to the first embodiment of the present invention is shown, (a) is a side view of the rotary die, and (b) is a side view of the rotary die in a different direction from that of (a). image 3 Shows the same rotary stamping die, (a) is a side view of the rotary stamping die, (b) is a side view of the rotary stamping die in a different direction from Figure (a), Figure 4 shows the construction of a rotary stamping die figure 2 Cross-sectional view of line AA in (a).

[0043] Such as Figure 4 , Figure 5 As shown, the rotary stamping die (10) fixes the rotatable rotary die (11) on the fixed base (31) through ...

Embodiment 2

[0073] A rotary press die according to a second embodiment of the present invention will now be described. Figure 8 The rotary die of the rotary press die according to the second embodiment of the present invention is shown, (a) is a cross-sectional view of the rotary press die in the state where pressurization is completed, and (b) is a cross-section of the rotary press die with the work plate removed picture.

[0074] The rotary press die (40) of this embodiment forms a working plate P whose shape is different from that of the first embodiment. Therefore, the shape of the rotating die (41) of the rotary stamping die (40), the shape of the horizontally moving cam (52), the vertically moving cam (53), the fixed die (54), etc. are different from those of the first embodiment, but basically Same construction.

[0075] In this embodiment, the rotary block (20) of the rotary press die in the first embodiment can be used for the rotary die (41). That is to say, in this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com