Laser control device

一种控制装置、激光器的技术,应用在仪器、光束源、光学记录头等方向,能够解决峰值保持电路检波效率下降、难以正确地检测峰值输出电平和偏置输出电平、监视器输出信号迟缓等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] (Embodiment 1)

[0048] Next, a laser control device according to an embodiment of the present invention will be described.

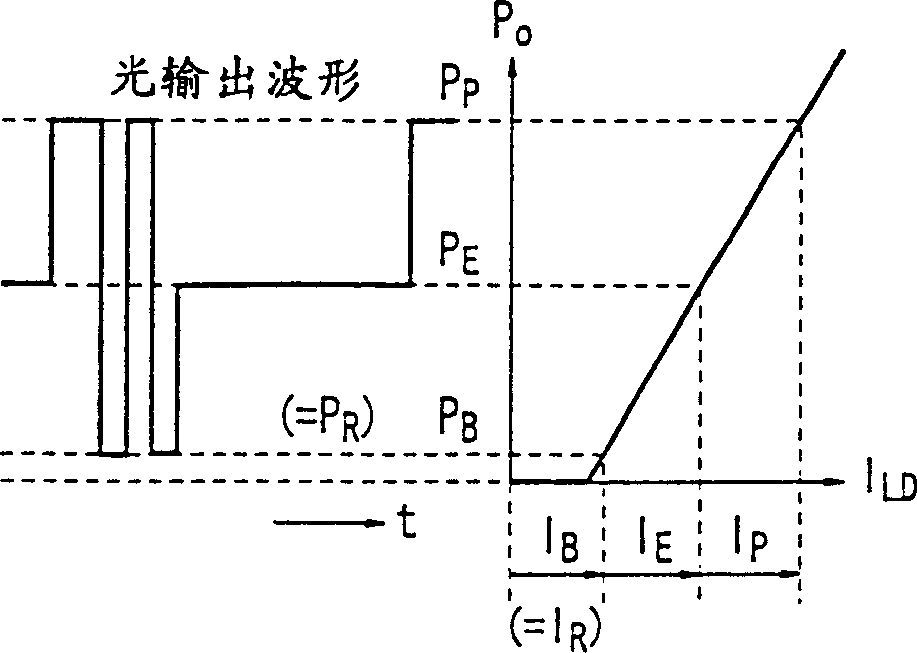

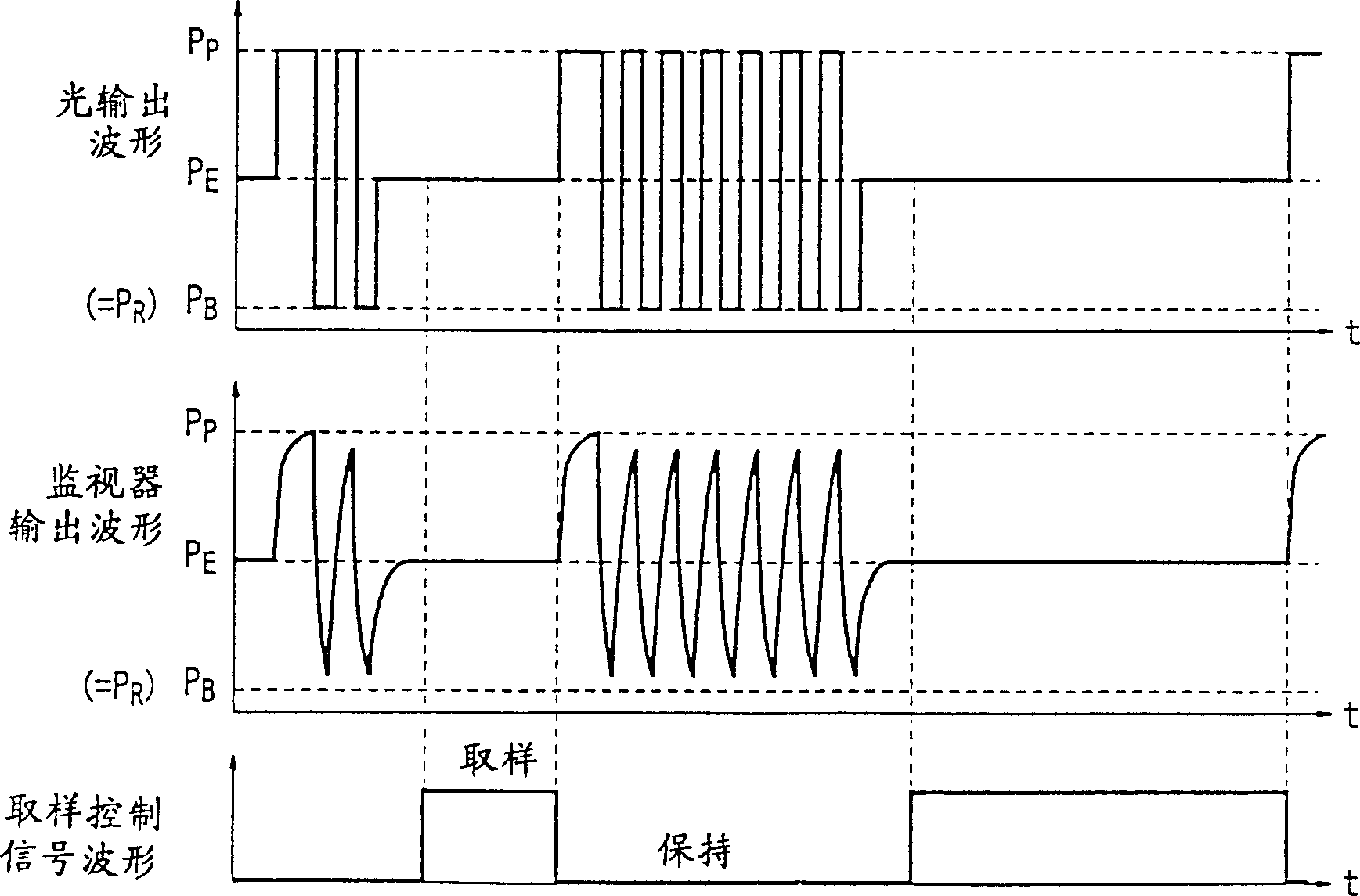

[0049] This embodiment 1 corresponds to the invention described in the first and second aspects of the present invention. The bottom peak power is controlled using the APC value at the time of reproduction immediately before recording, and the erasing power is controlled by a sample holder because the period is relatively long. After the power is detected, the APC control is performed directly, and the peak power is controlled according to the control value of the erasing power.

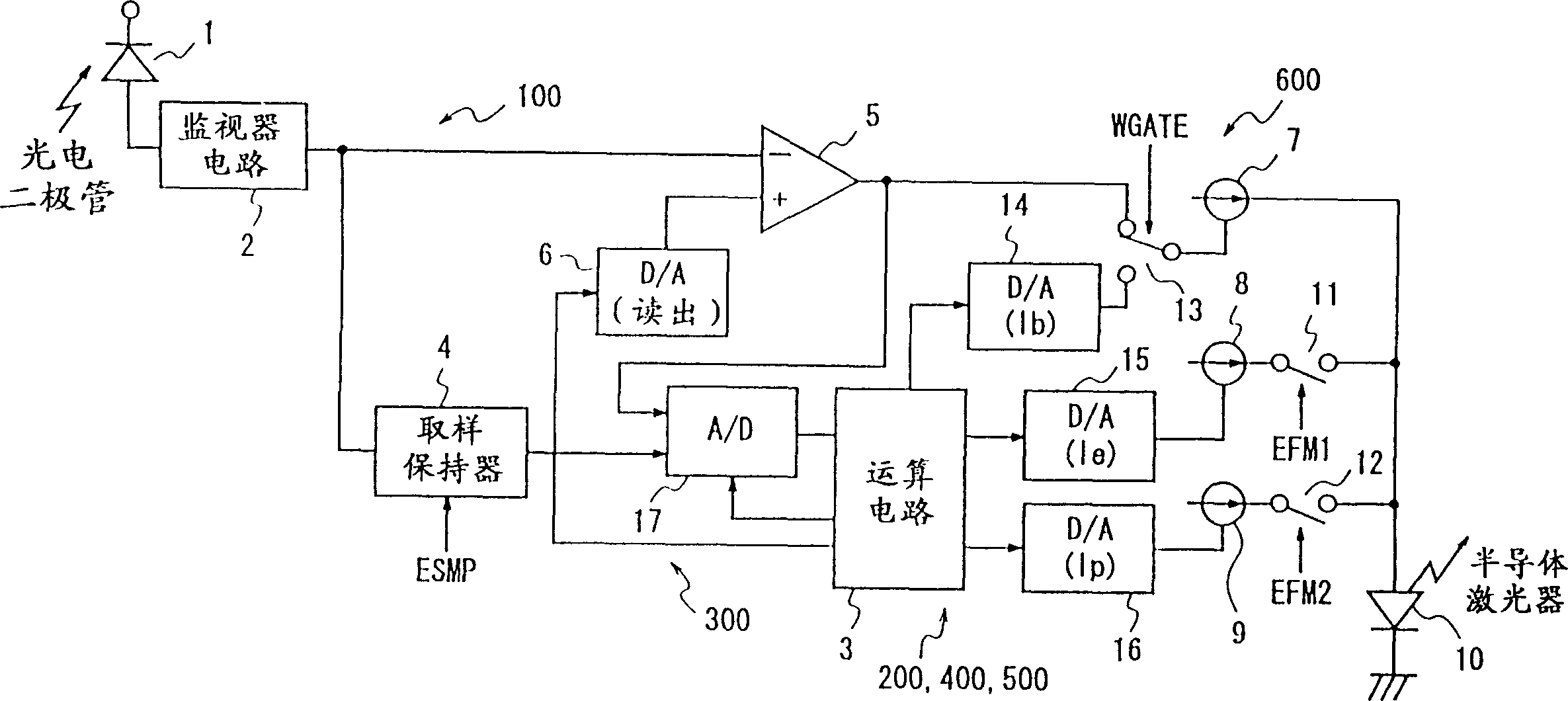

[0050] figure 1 A laser control device according to Embodiment 1 of the present invention is shown. exist figure 1 Among them, 10 is a semiconductor laser that irradiates laser light to the optical disk, 1 is a photodiode that receives light irradiated by the semiconductor laser 10, and 2 is a monitor circuit (current-voltage conversion device, current-voltage conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com