Rotary compressor, refrigeration cycle device, and method for manufacturing rotary compressor

A technology of a rotary compressor and a manufacturing method, which is applied in the direction of rotary piston machines, rotary piston pumps, machines/engines, etc., and can solve problems such as vane spring offset and inability to set vane springs with high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

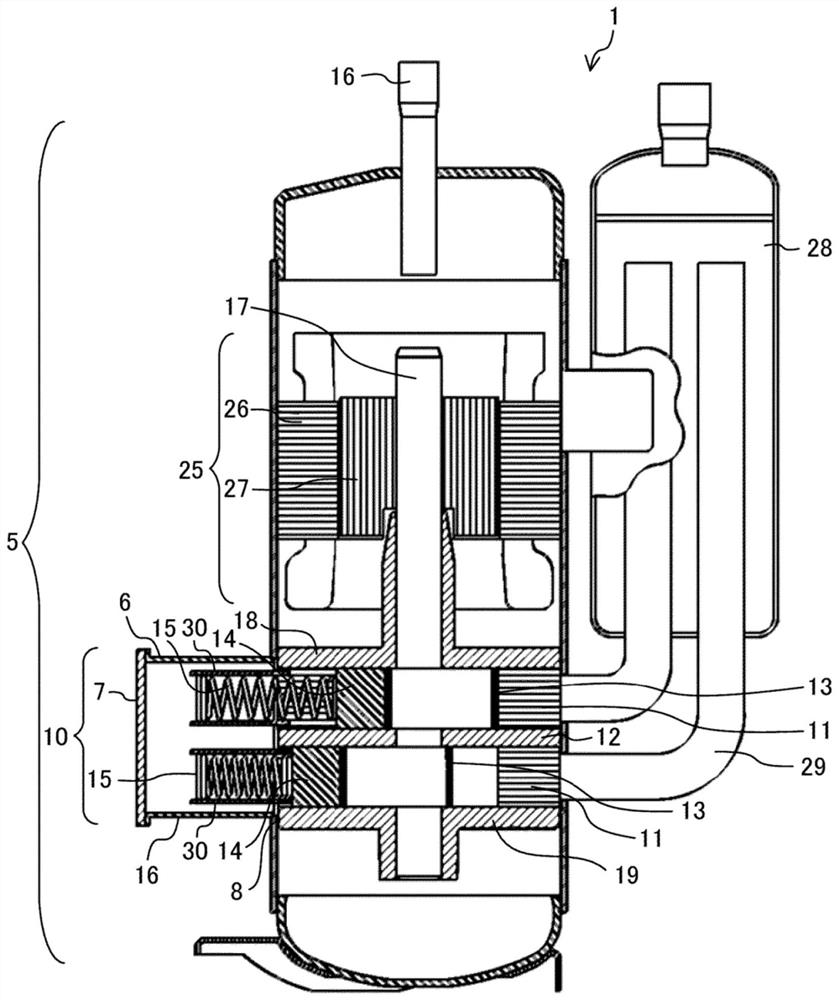

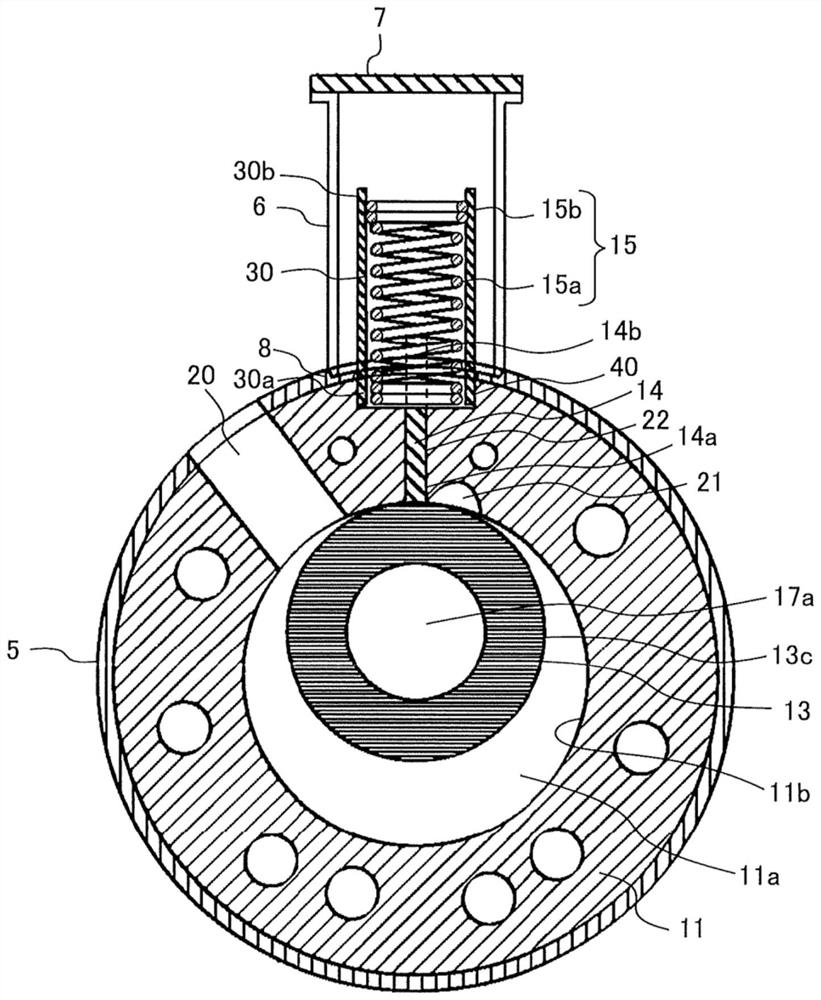

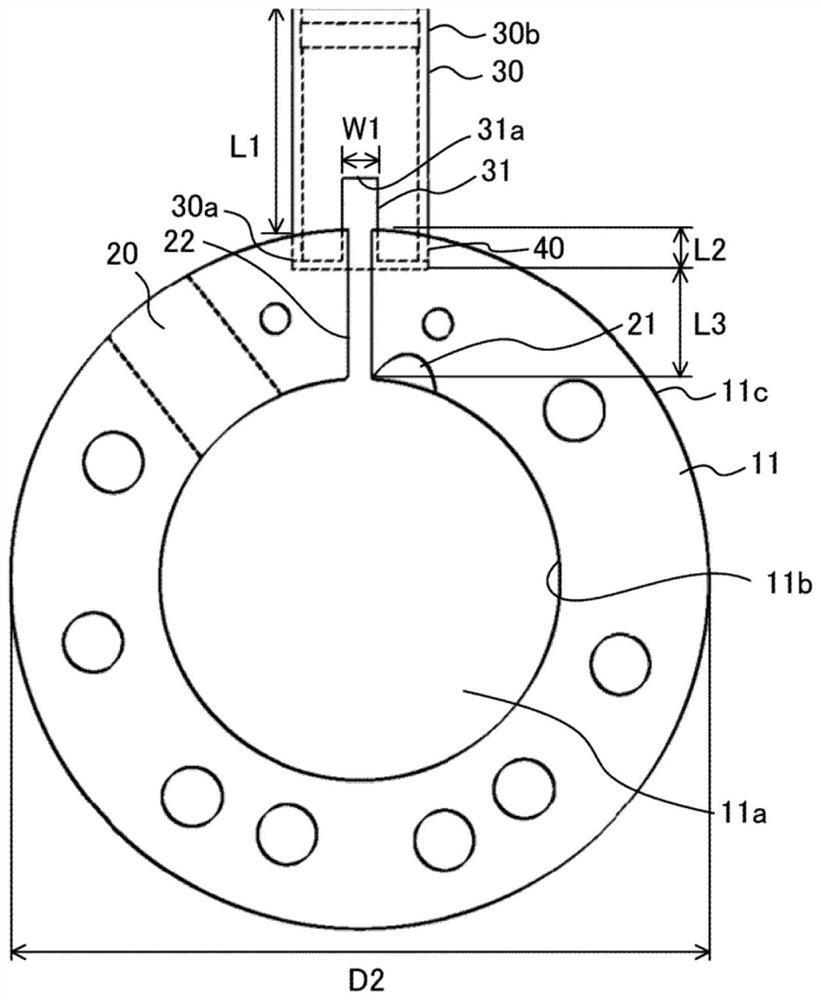

[0024] figure 1 It is a cross-sectional view showing a schematic configuration of the rotary compressor according to the first embodiment. figure 2 It is an enlarged transverse cross-sectional view of a compression mechanism part in the rotary compressor according to the first embodiment. image 3 It is an enlarged view which shows the connection structure of the spring guide of the rotary compressor which concerns on Embodiment 1, and a cylinder block. Wherein, in this specification, when referred to as "radial direction", "circumferential direction" and "axial direction" unless otherwise specified, they refer to the "radial direction", "circumferential direction" and "axial direction" of the cylinder, respectively. Axial".

[0025] The rotary compressor 1 includes, inside the airtight container 5 , an electric element 25 , a compression element 10 that compresses the refrigerant, and a rotating shaft 17 that transmits the driving force of the electric element 25 to the co...

Embodiment approach 2

[0116] The second embodiment relates to a refrigeration cycle apparatus including the rotary compressor 1 of the first embodiment.

[0117] Figure 11 It is a figure which shows the refrigerant circuit of the refrigeration cycle apparatus which concerns on Embodiment 2.

[0118] The refrigeration cycle apparatus 50 includes the rotary compressor 1 of the first embodiment, a condenser 51 , an expansion valve 52 serving as a decompression device, and an evaporator 53 . The gas refrigerant discharged from the rotary compressor 1 flows into the condenser 51, exchanges heat with the air passing through the condenser 51, becomes a high-pressure liquid refrigerant, and flows out. The high-pressure liquid refrigerant flowing out of the condenser 51 is decompressed by the expansion valve 52 to become a low-pressure gas-liquid two-phase refrigerant, and flows into the evaporator 53 . The low-pressure gas-liquid two-phase refrigerant flowing into the evaporator 53 exchanges heat with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com