String pressing mechanism and automatic playing device using same

A driving device and string technology, applied in stringed instruments, musical instruments, electroacoustic instruments, etc., can solve the problems of inconvenient maintenance, high cost, and difficult assembly, and achieve the effect of reducing failure rate, light weight, and assembly difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

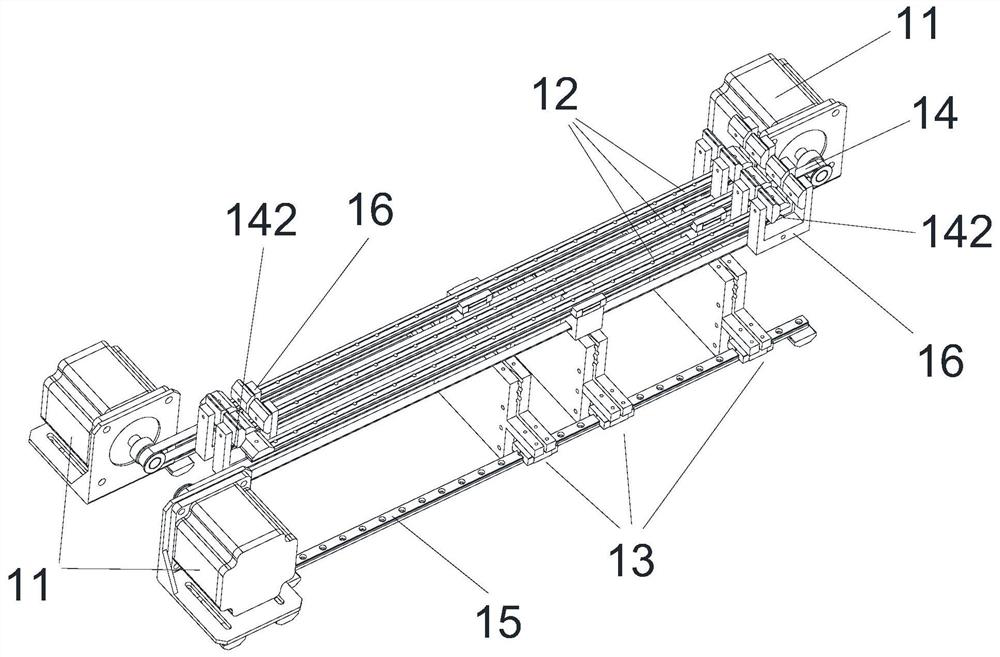

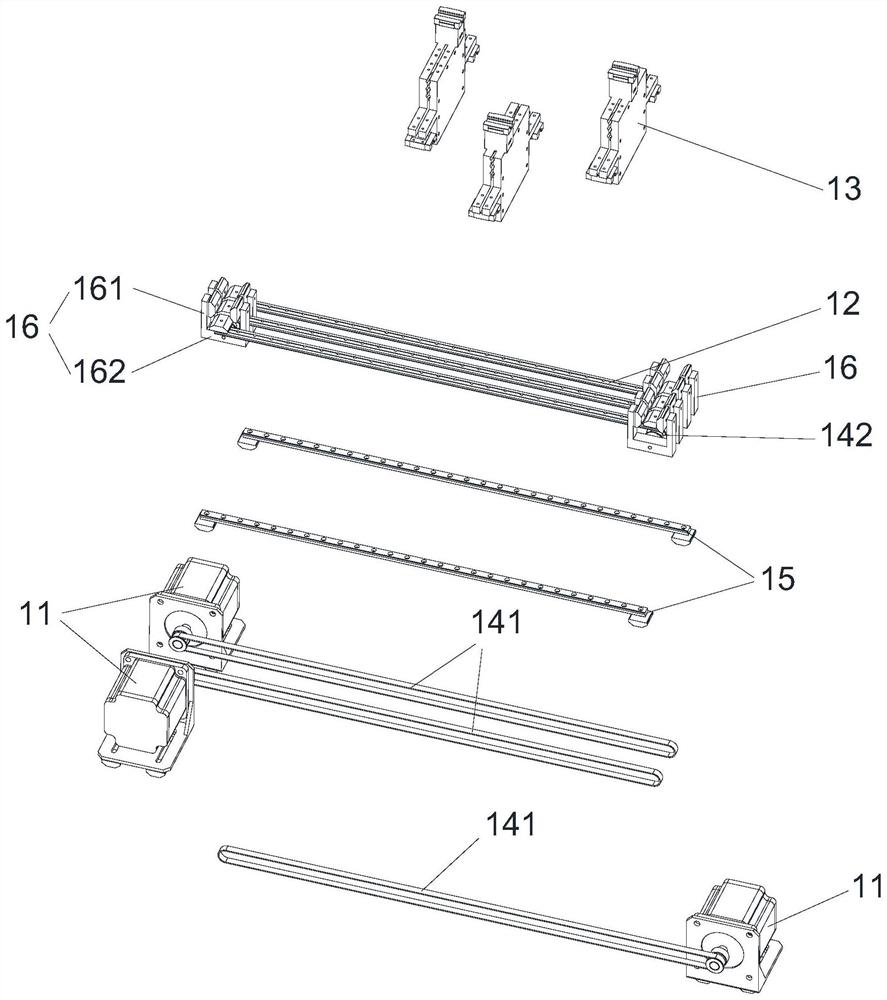

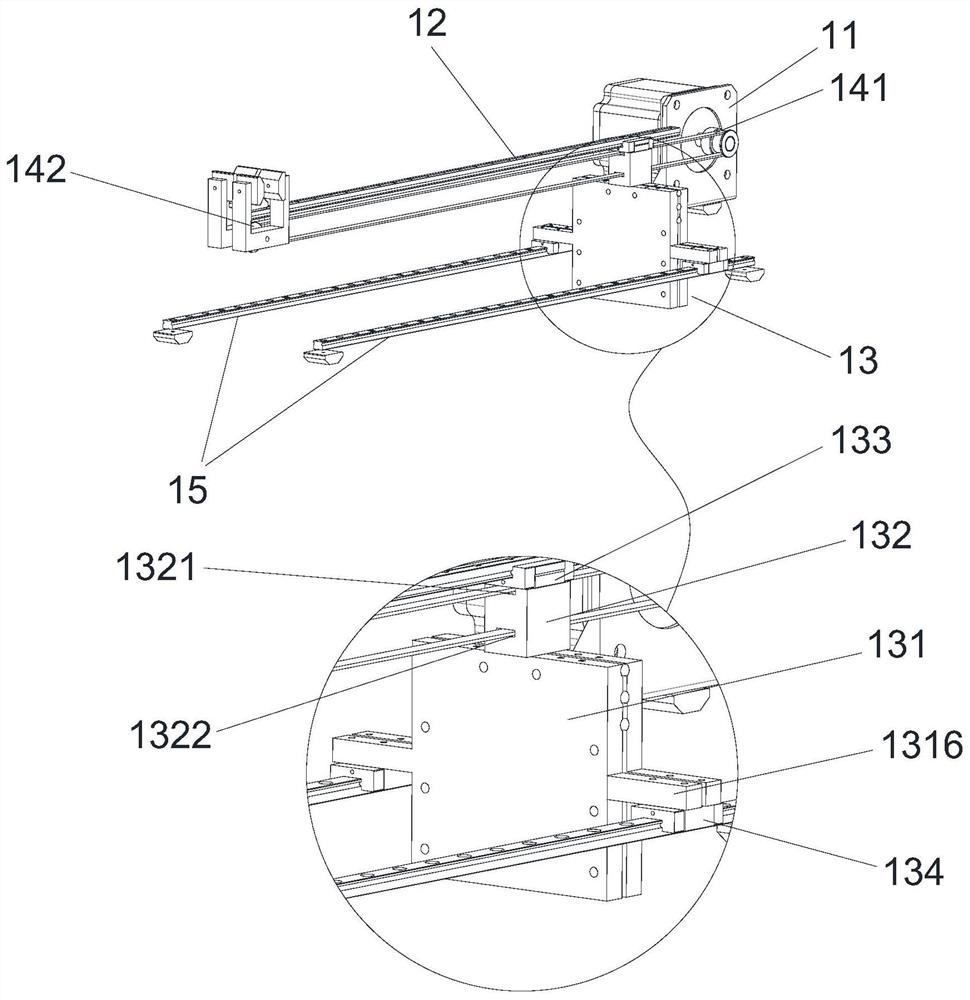

[0033] Please refer to Figure 1 to Figure 5 As shown, the embodiment of the present invention discloses a string pressing mechanism 1, which includes a bracket body (not shown in the figure) for relative fixing with the musical instrument body, and also includes several string pressing assemblies arranged above the strings, each of which The string pressing assembly includes a motor 11 installed on the bracket body and a first slide rail 12, a string pressing module 13 slidably arranged on the first slide rail 12 and a belt assembly 14 driven by the motor 11, the belt The assembly 14 includes a belt 141 and a pulley 142, the first slide rail 12 and the belt 141 are arranged parallel to the strings, the string pressing module 13 is connected with the belt 141, and the motor 11 controls the belt 141 to adjust the The stroke of the string pressing module 13 in the string length direction, each of the string pressing modules 13 includes a driving device (not shown in the figure),...

no. 2 example

[0046] Please refer to Figure 6 to Figure 13 As shown, the embodiment of the present invention also provides an automatic playing device, including a control system, and also includes the string pressing mechanism described in the first embodiment above, and the control system is at least used to control the motor and the driving device .

[0047] The plucking mechanism of the existing automatic playing device achieves the purpose of plucking the strings by setting a corresponding plucking cylinder and bracket group at each string. When plucking a string, two plucking cylinders that cooperate with each other are usually required. And some brackets with specific angles and lengths are realized. The structure is relatively complicated, the installation and positioning of the brackets are difficult, and the purchase and maintenance costs are high. pitch accuracy.

[0048] As yet another object of the present invention, in order to solve the technical problems of the above-ment...

no. 3 example

[0059] As an improvement to the strumming mechanism of the second embodiment above, in this embodiment, a first lifting mechanism is also provided between the "I"-shaped fixing frame and the steering gear mounting seat, and the "" Each horizontal bracket of the "glyph limiter is provided with a second lifting mechanism on both sides of the vertical bracket. The first lifting mechanism is used to raise or lower the height of the steering gear, and the second lifting mechanism is used to raise or lower the horizontal The height of one or both sides of the stand to change the height of the picks. Exemplarily, when the control system controls the first lifting mechanism below the steering gear mounting seat of any pizzicato assembly to rise, at the same time controls the second elevating mechanism on the side of the transverse bracket corresponding to the pizzicato assembly to rise, so as to lift the corresponding The height of the plectrum of the plucked string assembly reduces t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com