Novel high-temperature flat gate valve

A slab gate valve, high temperature technology, applied in the direction of valve device, valve details, sliding valve, etc., can solve the problems such as prone to jamming, achieve the effect of enhancing high temperature working characteristics and reliability, realizing automatic compensation, effective and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

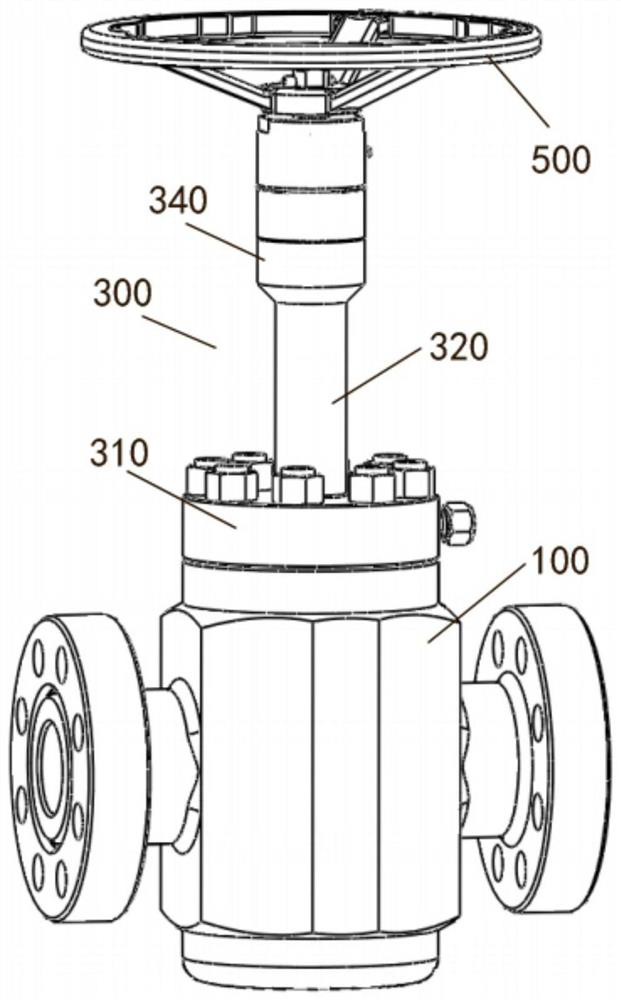

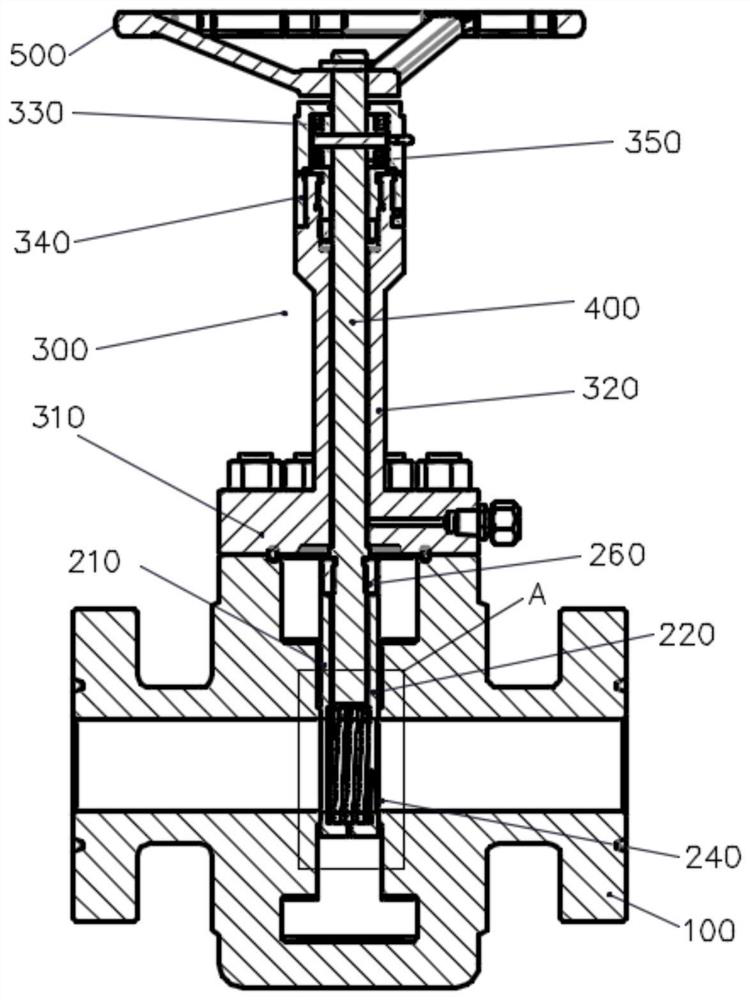

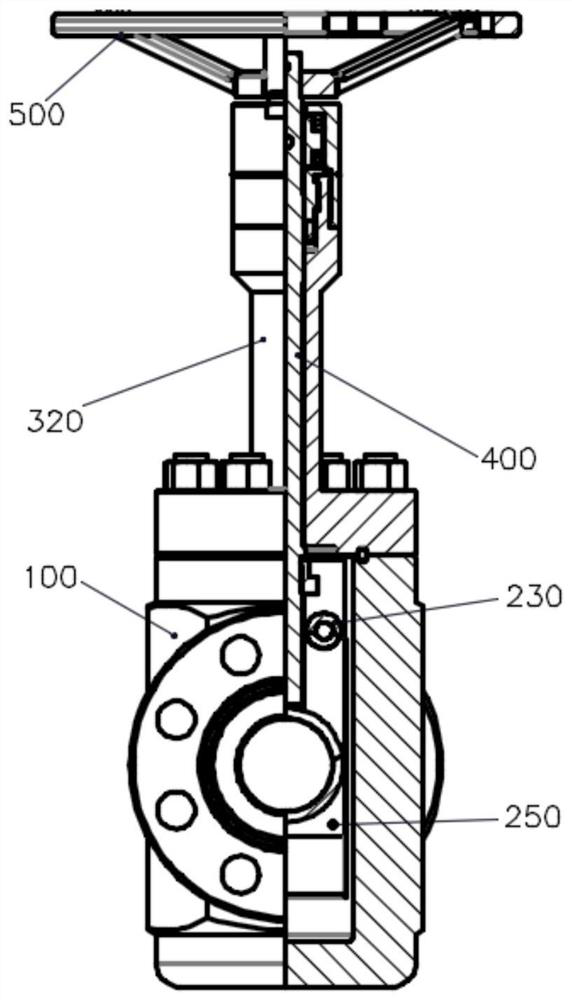

[0047] as attached Figure 1-3 As shown, a new high temperature slab gate valve includes an integrated valve body 100, a valve plate 200 arranged inside the valve body 100, a valve cover arranged above the valve body 100 and fixedly connected to the valve body 100 300 . The hand wheel 500 arranged above the valve cover 300 .

[0048] The contact surface between the valve plate 200 and the valve body 100 is provided with a sealing metal surfacing layer 600, and the valve stem 400 is connected above the valve plate 200; the handwheel 500 is fixedly connected to the end of the valve stem 400 away from the valve body 100, Rotating the hand wheel 500 drives the valve stem 400 to rotate, and then drives the valve plate 200 to move up and down, so as to realize the connection and blocking of the through hole of the valve plate 200 and the medium channel of the valve body 100 .

[0049] as attached Figure 4 As shown, the contact surface between the valve plate 200 and the valve bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com