Modification method for improving high-temperature oxidation resistance of titanium-based alloy

A high-temperature oxidation-resistant, titanium-based alloy technology, applied in the direction of electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of unsuitability for industrial production, decline in oxidation resistance, and poor effects, and achieve low modification costs , improve utilization, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

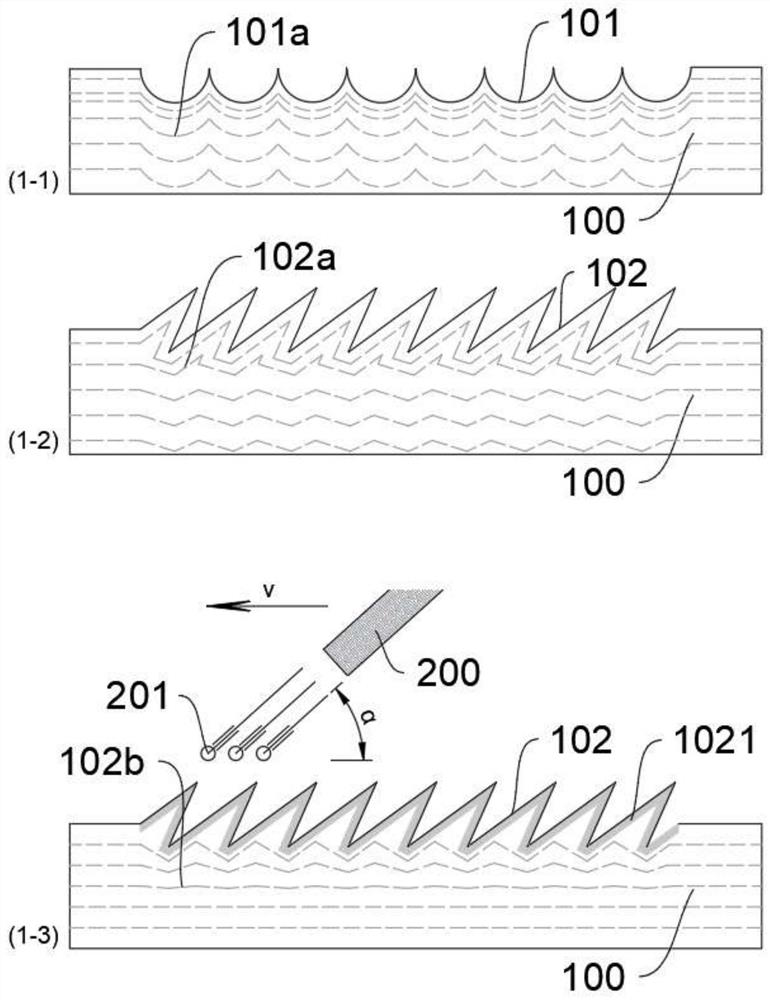

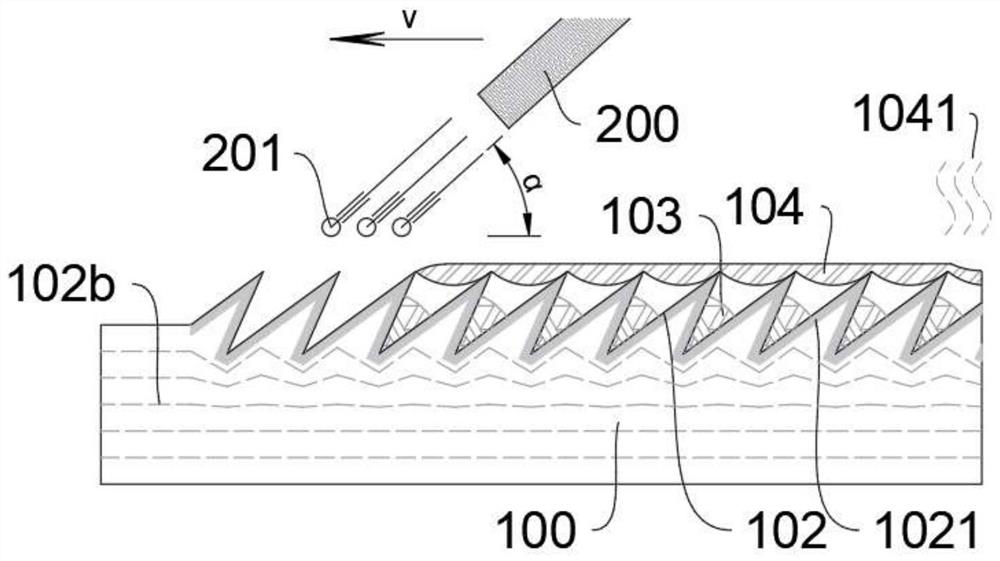

[0072] A modification method for improving the high-temperature oxidation resistance of titanium-based alloys, the method comprising:

[0073] The surface of the Ti-Al alloy that has undergone conventional pretreatment such as degreasing is subjected to sandblasting treatment, and then placed in a fluorine-containing system for anodic oxidation.

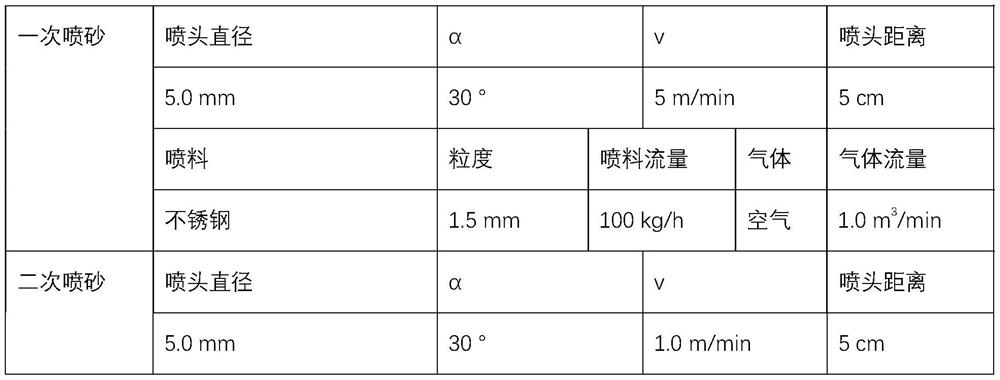

[0074] The specific operating parameters are shown in Table 1 below.

[0075] Table 1: Example 1 operating parameters

[0076]

[0077]

Embodiment 2

[0079] A modification method for improving the high-temperature oxidation resistance of titanium-based alloys, the method comprising:

[0080] The surface of the Ti-Al alloy that has undergone conventional pretreatment such as degreasing is subjected to sandblasting treatment, and then placed in a fluorine-containing system for anodic oxidation.

[0081] The specific operating parameters are shown in Table 2 below.

[0082] Table 2: Embodiment 2 operating parameters

[0083]

Embodiment 3

[0085] A modification method for improving the high-temperature oxidation resistance of titanium-based alloys, the method comprising:

[0086] The surface of the Ti-Al alloy that has undergone conventional pretreatment such as degreasing is subjected to sandblasting treatment, and then placed in a fluorine-containing system for anodic oxidation. The specific operating parameters are shown in Table 3 below.

[0087] Table 3: Embodiment 3 operating parameters

[0088]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com