Polyimide sound absorption foam with spherical pit microstructure and preparation method of polyimide sound absorption foam

A polyimide sound-absorbing and micro-structure technology, which is applied in the direction of sound-producing equipment and instruments to achieve the effect of improving the degree of transformation, the degree of improvement is significant, and the operation process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

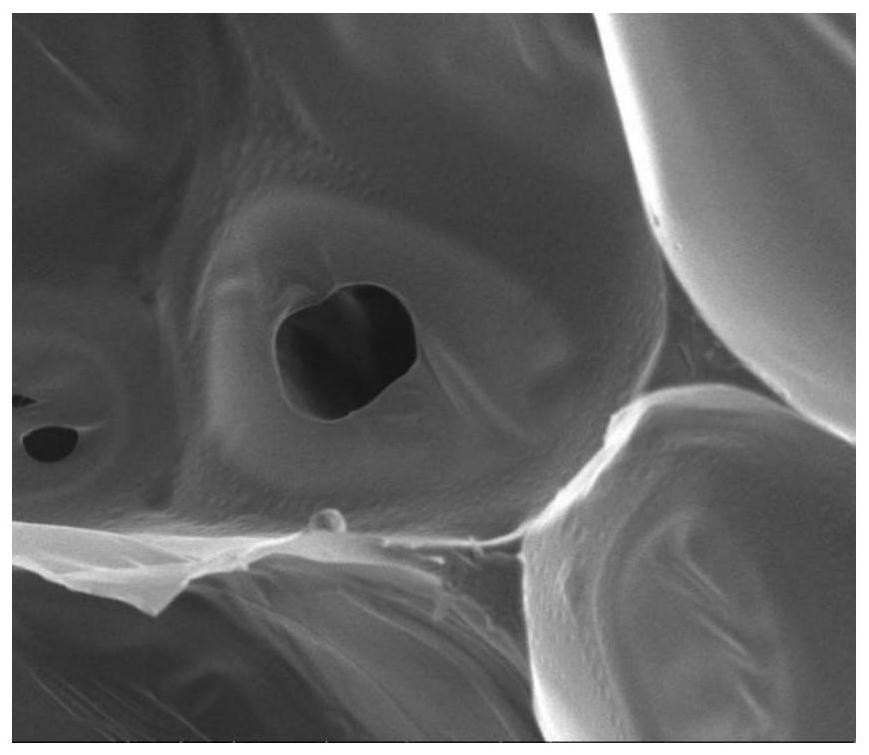

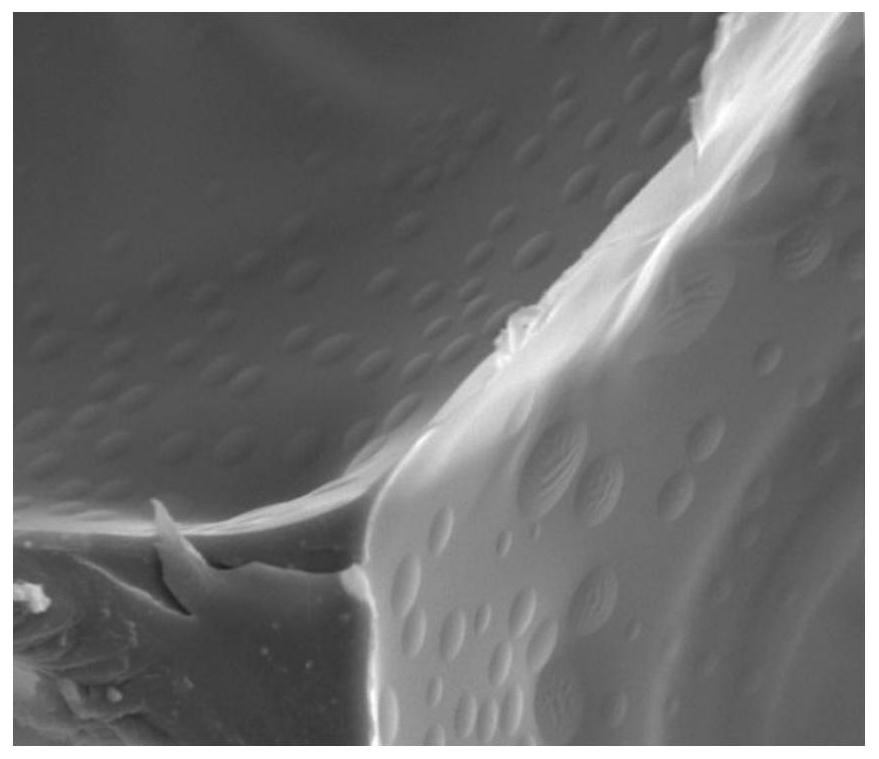

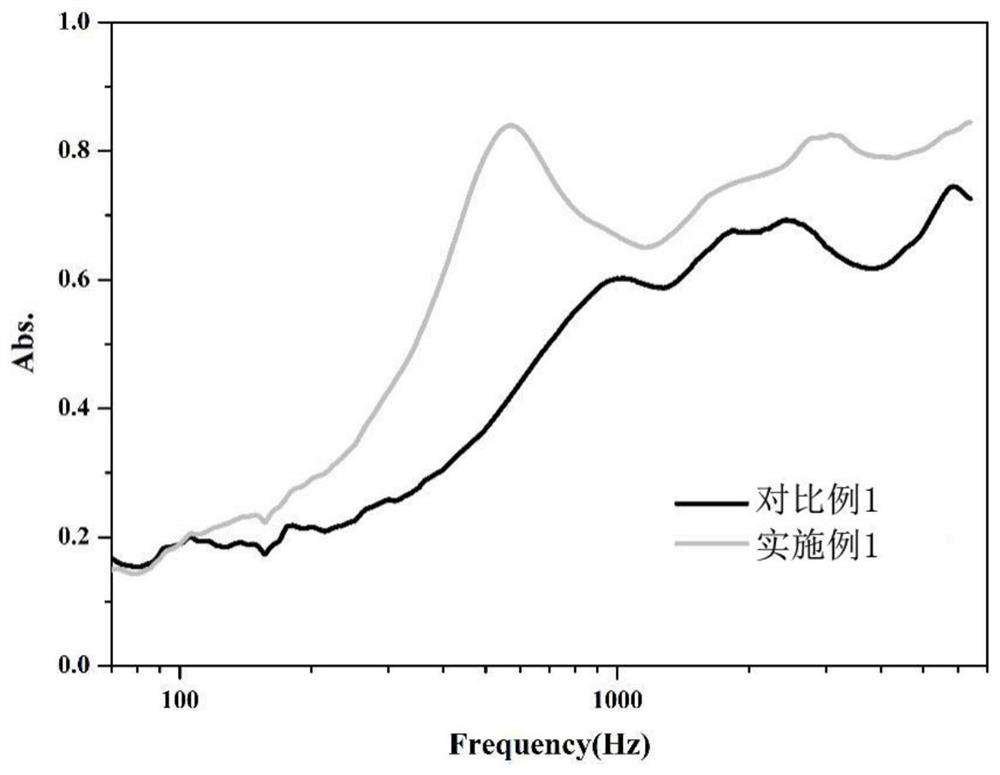

[0033] In a disposable plastic cup, 40g of N,N-dimethylformamide solution of 45% 3,3',4,4'-benzophenone tetra-acid dimethyl, 3.2g of T12 , Dabco33, a catalyst prepared from triethanolamine at a mass ratio of about 1:2:5, 20g of a surfactant prepared from AK8805 and PEG600 at a mass ratio of 1:1, and 4.8g of deionized water, mixed evenly as Foaming white material; weigh 60g of polyisocyanate and add it to a disposable plastic cup as foaming black material; after mixing the foaming white material and foaming black material evenly, foam molding to obtain a polyimide foam intermediate ; Demoulding the foam intermediate and placing it in a blast drying oven at 180° C. for 2 hours, finally obtaining a polyimide sound-absorbing foam with a microstructure on the inner surface of spherical pits. see figure 1 with figure 2 As shown, the diameter of the spherical pit structure on the resin skeleton of the foam matrix and the surface of the window is 6-8 μm, and wrinkles appear on the ...

Embodiment 2

[0036] In a disposable plastic cup, 44g of N,N-dimethylacetamide solution of 47% 3,3',4,4'-biphenyltetraic acid diethyl ester, 3.2g of T12, Dabco33 , triethanolamine catalyst prepared in a mass ratio of about 1:2:5, 22g of surfactant prepared by DC193 and PEG1000 in a mass ratio of 0.8:1, 4.8g of deionized water, mixed evenly as foam White material; The polyisocyanate that weighs 60g joins in the disposable plastic cup, as foaming black material; After foaming white material and foaming black material are mixed, foam molding obtains polyimide foam intermediate; The foam intermediate was released from the mold and placed in a blast drying oven at 180°C for 2 hours to obtain a polyimide sound-absorbing foam with a microstructure on the inner surface of spherical pits. The diameter of the spherical pit structure on the resin skeleton of the foam matrix and the surface of the window is 8-10 μm, and wrinkles appear on the surface of some pits.

[0037] The polyimide sound-absorbin...

Embodiment 3

[0039]In a disposable plastic cup, 25g of N-methylpyrrolidone solution of 77% pyromellitic acid diisopropyl, 3.2g of T12, Dabco33, triethanolamine in a mass ratio of about 1:2:5 Catalyst prepared in proportion, 23g of surfactant prepared by PMX200 and PTMG2000 at a mass ratio of 1.2:1, 4.8g of deionized water, mixed evenly as foaming white material; weighing 60g of polyisocyanate added to a disposable In a plastic cup, it is used as a foaming black material; after mixing the foaming white material and the foaming black material evenly, foaming is formed to obtain a polyimide foam intermediate; the foam intermediate is demoulded and placed in a blast drying at 180°C Keep it in the box for 2 hours, and finally obtain a polyimide sound-absorbing foam with a microstructure on the inner surface of spherical pits. The diameter of the spherical pit structure on the resin skeleton of the foam matrix and the surface of the window is 5-7 μm, and wrinkles appear on the surface of some pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com