Colored partridge spot Jianzhan and preparation process thereof

A preparation process, the technology of partridge, applied in the field of Jianzhan and its preparation process, can solve the problems of difficult control of formula, firing atmosphere and temperature curve, no display of oil drop crystal spots, high difficulty of firing, etc., and achieve gorgeous colors Extreme, strong three-dimensional effect, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation process of the colored partridge spot Jianzhan comprises the following steps:

[0043] (1) Prepare the green body, the first glaze slurry and the second glaze slurry, wherein:

[0044] The green body is prepared by the following method: mixing 7 parts by weight of kaolin and 3 parts by weight of laterite, pulverizing, elutriating, passing through an 80-mesh sieve, press filtration, mud refining, and aging to obtain the green body raw material; Body raw materials are drawn and formed, trimmed, bisque fired, and cooled to obtain a green body;

[0045] The laterite and kaolin are all taken from Shuiji Town, Jianyang District, Nanping City, Fujian Province;

[0046] The biscuit firing is that the temperature of the kiln is raised from normal temperature to 800° C. at a constant speed within 6 hours, then the furnace is stopped and cooled.

[0047] The first glaze slurry is prepared by the following method: mix 8 parts by weight of glaze ore, 1 part by weig...

Embodiment 2 and Embodiment 3

[0065] Jianzhan is very sensitive to the parameters of the preparation process, and a small change in the process parameters will have a great adverse effect on the appearance and other characteristics of the final product of the Jianzhan, and even lead to the failure of the preparation of the Jianzhan. Therefore, the requirements for the preparation process of Jianzhan are very strict. . Example 2 and Example 3 prepared Jianzhan according to the same preparation process as Example 1, and the characteristics of Jianzhao prepared in Example 2 and Example 3 were basically similar to those prepared in Example 1, and the yield was also roughly the same. The results show that the yield of Jianzhan prepared by the preparation process of Example 1 is high, and the method has good repeatability, strong stability, and is easy for large-scale production.

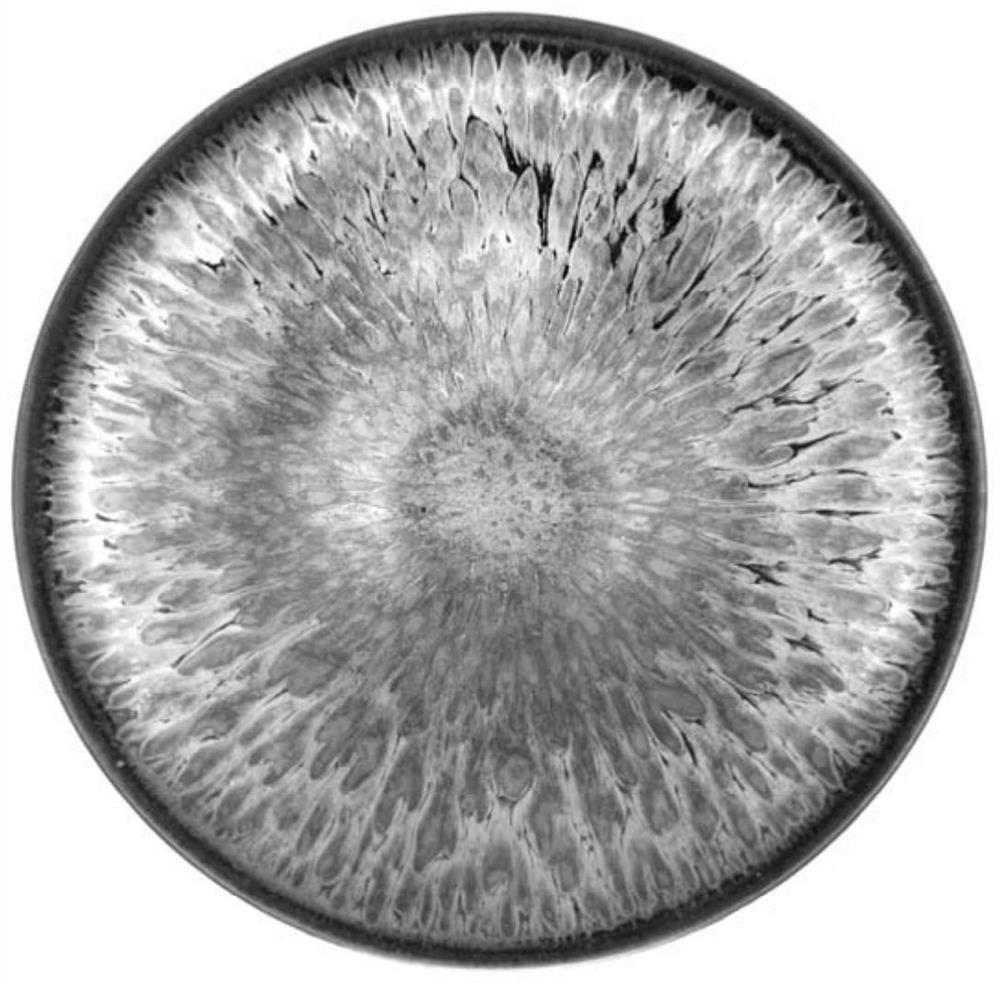

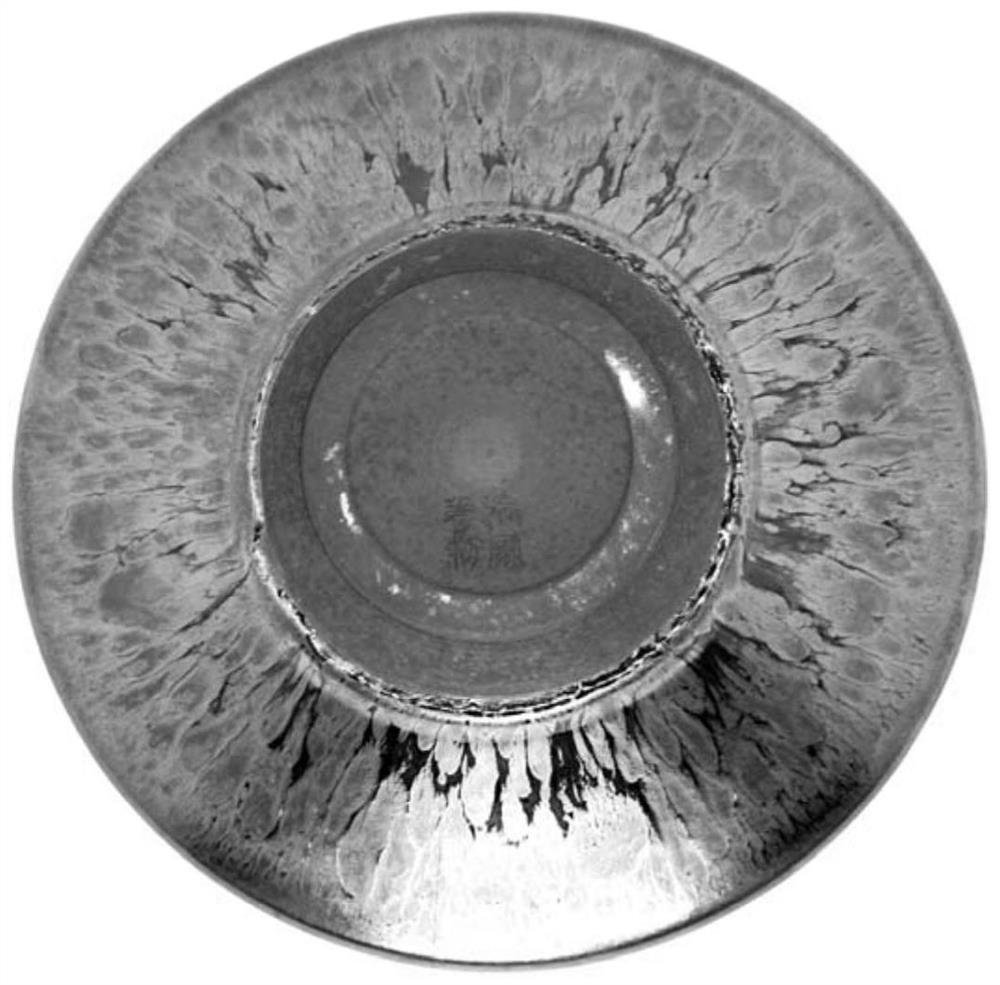

[0066] Evaluation of Colored Partridge Spot Jianzhan

[0067] The color partridge spot that embodiment 1 makes builds a reference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com