Composite Air Tank

A technology of composite materials and air storage tanks, which is applied in the field of composite material air storage tanks, can solve the problems of axial and radial winding, radial winding cannot strengthen water discharge holes, and axial winding cannot be carried out, so as to achieve the effect of ensuring safety strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

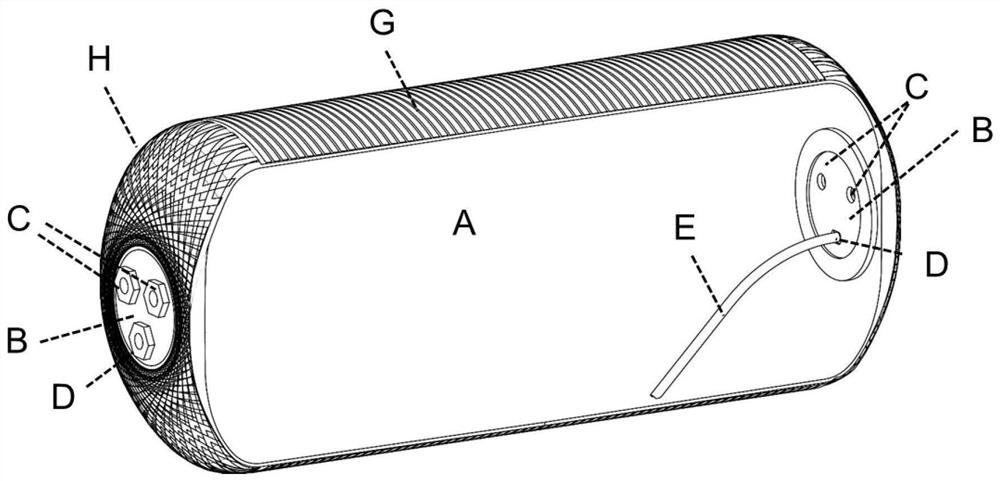

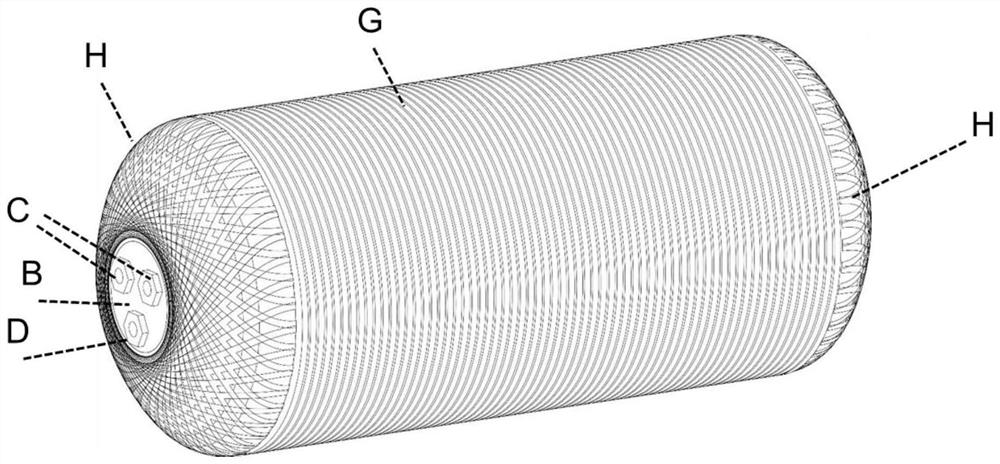

[0029] like Figure 1-7 As shown in the figure, in a composite air storage cylinder of the present invention, inserts B are arranged at both ends of the inner tank A, and an exhaust pipe joint C and a drain pipe joint D are arranged on the insert B, and the internal drain pipe E is connected to the drainage pipe. On the pipe joint D, the end of the inner drain pipe E is connected to the bottom of the air storage cylinder, and the outer layer is a fiber resin composite winding layer, which includes an axial winding layer H and a radial winding layer G (that is, axial winding and radial winding).

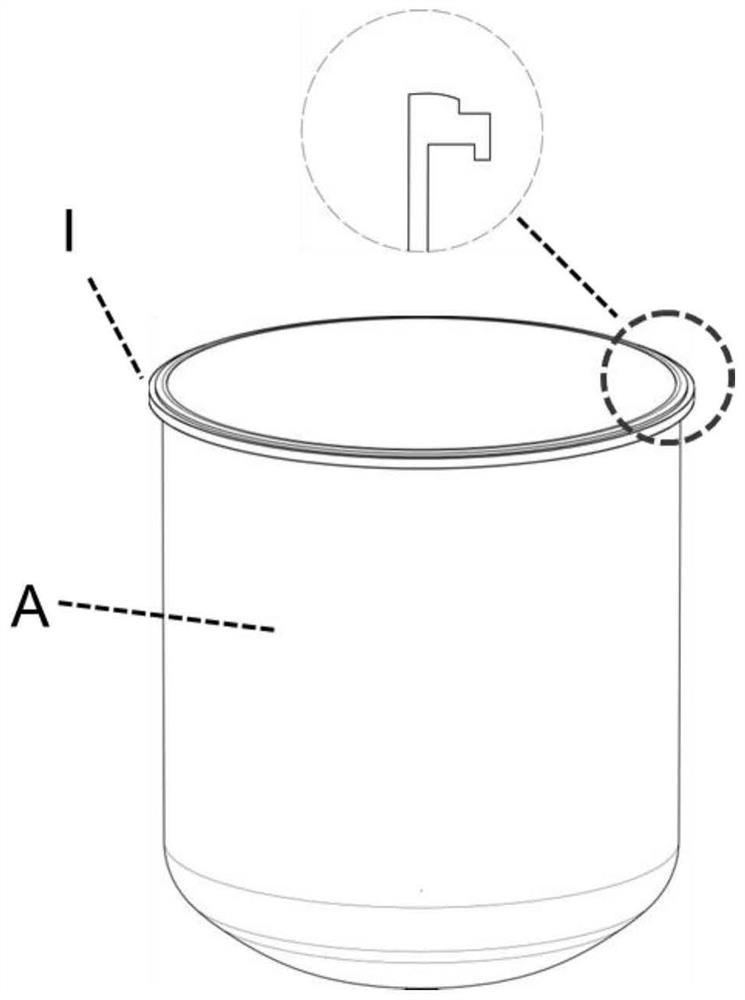

[0030] In this embodiment, three threaded holes are preset on the insert B, such as figure 2 The equiangular arrangement is shown, the insert B is embedded in the mold in advance, and injection molded together with the inner tank A. The material of the inner tank A is nylon 66+GF33 material, such as image 3 As shown, the welding boss I in the inner pot A is arranged to the outside...

Embodiment 2

[0035] A composite air storage cylinder, inserts B are arranged on both ends of the inner bladder A, an exhaust pipe joint C and a drain pipe joint D are arranged on the insert B, and the internal drain pipe E is connected to the drain pipe joint D. The end of the drain pipe E is connected to the bottom of the air storage cylinder, and the outer layer is a fiber resin composite winding layer. The fiber resin composite winding layer includes an axial winding layer H and a radial winding layer G (ie, axial winding and radial winding are adopted).

[0036] In this embodiment, three threaded holes are preset on the insert B, such as figure 2 The equiangular arrangement is shown, the insert B is embedded in the mold in advance, and injection molded together with the inner tank A. The material of the inner tank A is nylon 6+GF25 material, combined with Image 6 , the welding boss I in the inner tank is arranged inward.

[0037] The inner tank A consists of two halves. The two halv...

Embodiment 3

[0041] A composite air storage cylinder, inserts B are arranged on both ends of the inner bladder A, an exhaust pipe joint C and a drain pipe joint D are arranged on the insert B, and the internal drain pipe E is connected to the drain pipe joint D. The end of the drain pipe E is connected to the bottom of the air storage cylinder, and the outer layer is a fiber resin composite winding layer. The fiber resin composite winding layer includes an axial winding layer H and a radial winding layer G (ie, axial winding and radial winding are adopted).

[0042] In this embodiment, three threaded holes are preset on the insert B, such as figure 2 The equiangular arrangement is shown, the insert B is embedded in the mold in advance, and blow-molded together with the inner tank A, and the material of the inner tank A is PE material. The surface of the inner tank A is polished with 800-grit sandpaper, and then the surface of the inner tank is filament wound. In this embodiment, the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com