Invisible tire decorative cover and preparation method thereof

A technology for decorative covers and tires, applied to wheel covers, wheels, transportation and packaging, etc., can solve the problems of low emissivity, general infrared stealth effect, easy to form strong reflection points, etc., achieve low cost, and improve camouflage and stealth performance , Infrared stealth performance good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

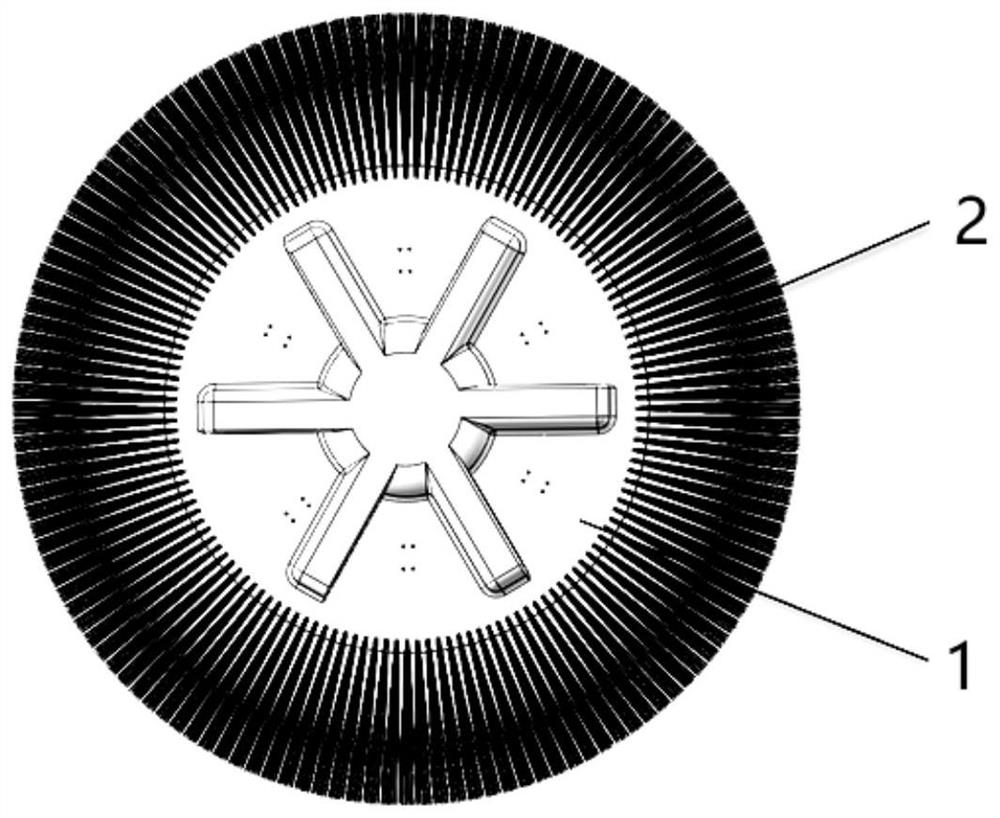

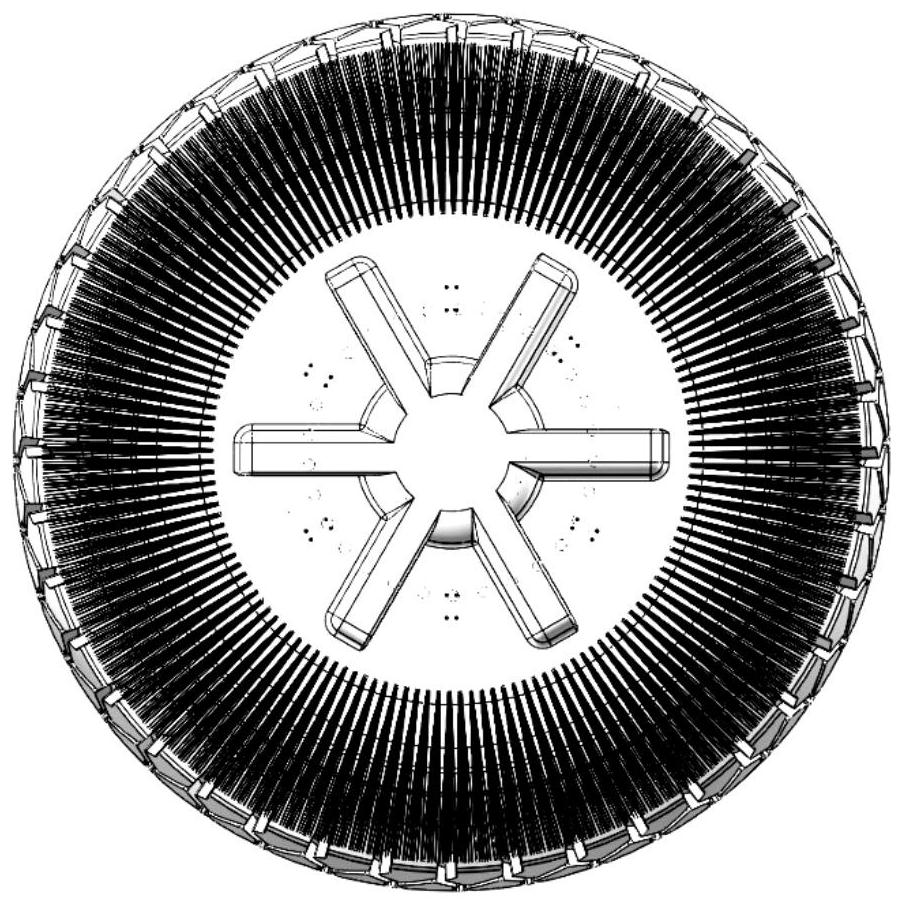

[0038] A kind of invisible tire decorative cover, its structure is as follows figure 1 As shown, the hubcap 1 and the camouflage grass 2 are included, the inner side of the hubcap 1 has a fixed bracket, and the fixed bracket fixes the hubcap on the vehicle hub; the hubcap 1 is a multi-layer structure, and its structure is as follows: figure 2 As shown, it includes substrate 16, infrared stealth coating, radar absorbing coating 13, metal reflective layer 12 and protective layer 11 in sequence; when fixedly connected with the vehicle hub, the protective layer 11 is located near the side of the vehicle hub; The camouflage grass is pasted on the surface of the base material 16 of the hubcap 1 . The specific material selection and optimal design of layer parameters for each layer in the hub cover 1 are as follows:

[0039] Substrate 16 is plastic or fiberglass material material; When substrate 16 is plastic material, described plastic comprises a kind of in epoxy resin, vinyl est...

Embodiment 2

[0047] A kind of preparation method of invisible tire decorative cover:

[0048] Step 1: Preparation of hubcap plastic substrate

[0049] A hub cover metal mold is prepared, and an ABS plastic material is used to prepare a plastic hub cover through an injection molding method.

[0050] Step 2: Preparation of other coatings on the hubcap

[0051] Preparation of phase change microcapsule cooling coating, SiO 2 Airgel thermal insulation coatings, radar absorbing coatings, conductive coatings and polyurea coatings, according to figure 2 The sequence shown is sprayed on the surface of the base material of the hub cover in turn, and the thickness of each layer is 1.5mm, 2mm, 0.8mm, 0.2mm, 1mm, and put into the curing oven for drying.

[0052] Step 3: Camouflage Grass Preparation

[0053] Spray the prepared low-emissivity paint on the surface of a 40 μm thick polyethylene film, the thickness of the sprayed coating is about 60 μm, then cut the cured film into a grass-like structu...

Embodiment 3

[0055] Step 1: Preparation of FRP substrate for hubcap

[0056] Prepare the metal mold of the hub cover, choose epoxy resin as the base material, glass fiber as the reinforcing fiber, and prepare the hub cover by RTM process.

[0057] Step 2: Preparation of other coatings on the hubcap

[0058] Phase-change microcapsule cooling coatings, hollow glass microsphere heat-insulating coatings, radar absorbing coatings, conductive coatings and polyurea coatings were prepared respectively, according to figure 2 The sequence shown is sprayed on the surface of the hubcap base material in turn, and the thickness of each layer is 1mm, 2mm, 0.6mm, 0.3mm, 1.5mm, and put into a curing oven for drying.

[0059] Step 3: Camouflage Grass Preparation

[0060] Prepare a low-emissivity coating by spraying on the surface of the polypropylene film after 30 μm. The thickness of the sprayed coating is about 50 μm. After curing, it is cut into a grass-like structure and tied into a ring pad with a w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com